Flame-retardant corrosion-resistant rubber material and preparation method thereof

A rubber material and corrosion-resistant technology, applied in the field of flame-retardant and corrosion-resistant rubber materials and their preparation, can solve problems such as hardening and inelasticity, corrosion of cable sheaths, and non-fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

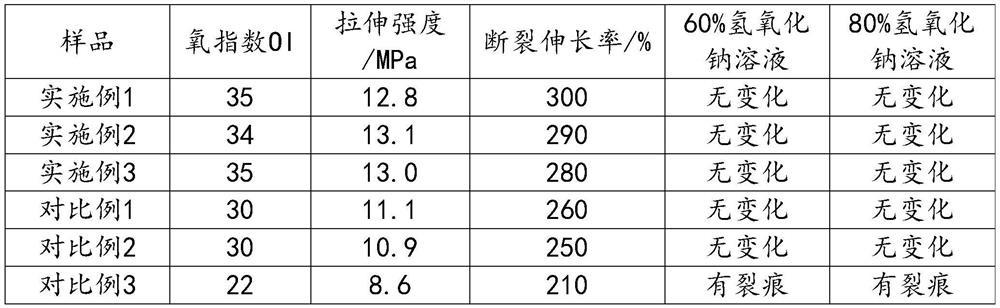

Examples

Embodiment 1

[0035] A flame retardant corrosion-resistant rubber material, including 60 parts of natural rubber, 30 neoprene, 10 composite fibers, 5 parts of modified graphene, 5 polystyrene, 1 vulcanizing agent 2 stearic acid, 3 zinc oxide, 3 anti-aging agents, 10 paraffin and 1 promoter;

[0036] The flame retardant corrosion-resistant rubber material is made of the following steps:

[0037] In the first step, the natural rubber was placed in an oven for 12 h at 70 ° C, and then cut into strips, the initial temperature of the controller was 80 ° C, the rotor speed 60R / min, and the natural rubber strip and neoprene were put into secret. In the meager, after mixing 20 min, the composite fiber, zinc oxide, modified gossipide and polystyrene are added to the mesenchym, and then transferred to the open mill after 30 minutes, and the vulcanizing agent, stearic acid, and anti-age Agents, paraffin and accelerators, mix 30 min to obtain a mixed rubber;

[0038] In the second step, the mixture obtai...

Embodiment 2

[0052] A flame retardant corrosion-resistant rubber material, including the following weight materials: 80 parts of natural rubber, 35 parts of neoprene, 12 composite fibers, 8 parts of modified graphene, 7 parts of polystyrene, 1.5 vulcanizers , 3 stearic acids, 4 zinc oxide, 4 dispensing agents, and 2 paraffin and 2 servants;

[0053] The flame retardant corrosion-resistant rubber material is made of the following steps:

[0054] In the first step, the natural rubber was placed in an oven for 12 h at 70 ° C, and then cut into strips, the initial temperature of the controller was 80 ° C, the rotor speed 60R / min, and the natural rubber strip and neoprene were put into secret. In the meager, after mixing 20 min, the composite fiber, zinc oxide, modified gossipide and polystyrene are added to the mesenchym, and then transferred to the open mill after 30 minutes, and the vulcanizing agent, stearic acid, and anti-age For agents, paraffin and accelerators, mixing 40 min to obtain a m...

Embodiment 3

[0069] A flame retardant corrosion-resistant rubber material, including 60-100 parts of natural rubber, 40 neoprene, 15 composite fibers, 10 modified oxide oxide, 8 parts of polystyrene, sulfurization agent 2 copies of stearic acid, 5 zinc oxide, 5 dispensing agents, and 1 paraffin and 3 paraffin;

[0070] The flame retardant corrosion-resistant rubber material is made of the following steps:

[0071] In the first step, the natural rubber was placed in an oven for 12 h at 70 ° C, and then cut into strips, the initial temperature of the controller was 80 ° C, the rotor speed 60R / min, and the natural rubber strip and neoprene were put into secret. In the meager, after mixing 20 min, the composite fiber, zinc oxide, modified gossipide and polystyrene are added to the mesenchym, and then transferred to the open mill after 30 minutes, and the vulcanizing agent, stearic acid, and anti-age Division, paraffin and accelerator, mix 50 min to get a mixed glue;

[0072] In the second step, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com