Optical film and method for manufacturing optical film

A manufacturing method and technology for optical films, applied in the field of optical films, can solve the problems of increased retardation, no mention of sliding property, retardation, etc., and achieve low retardation characteristics, excellent roll stability, and excellent brittleness resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

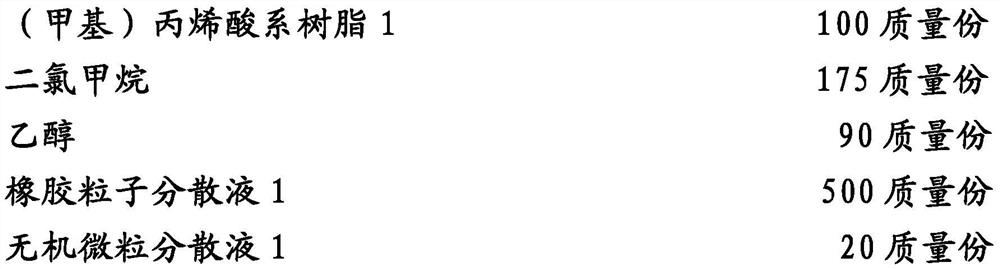

[0197] The solvent used for the preparation of the dope contains at least an organic solvent (good solvent) capable of dissolving the (meth)acrylic resin. Examples of good solvents include chlorine-based organic solvents such as dichloromethane, and non-chlorinated organic solvents such as methyl acetate, ethyl acetate, acetone, and tetrahydrofuran. Among them, dichloromethane is preferable.

[0198] As a solvent used for the preparation of dope, a poor solvent may be contained further. Examples of poor solvents include linear or branched aliphatic alcohols having 1 to 4 carbon atoms. When the ratio of the alcohol in the dope increases, the membrane-like product tends to gel, and the peeling from the metal support becomes easy. Examples of straight-chain or branched-chain aliphatic alcohols having 1 to 4 carbon atoms include methanol, ethanol, n-propanol, isopropanol, n-butanol, sec-butanol, and tert-butanol. Among these, ethanol is preferable in view of the stability of th...

Embodiment

[0230] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to these Examples. In addition, in an Example, the expression of "part" or "%" is used, and unless otherwise indicated, it means "part by mass" or "% by mass".

[0231] "Preparation of (meth)acrylic resin"

[0232] (Meth)acrylic resins 1 to 5 having the following compositions were synthesized according to a conventionally known synthesis method.

[0233] [Synthesis of (meth)acrylic resin 1]

[0234] According to conventional methods, synthesized (methyl ) Acrylic resin 1. The weight average molecular weight Mw of the (meth)acrylic resin 1 was 2 million.

[0235] [Synthesis of (meth)acrylic resin 2]

[0236] According to the conventional method, synthesized (methyl methacrylate) (methyl methacrylate) (50 mole %) / N-phenylmaleimide (25 mole %) / 2-ethylhexyl acrylate (25 mole %) ) Acrylic resin 2. The weight average molecular weight Mw of the (meth)ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com