A kind of bacterial cellulose membrane and breast patch and preparation method thereof

A technology of bacterial cellulose membrane and patch, which is applied in the field of medical biomaterials, can solve the problem that cells cannot grow ideally on it, and achieve the goal of helping breast repair, improving the safety of clinical use, and enhancing clinical compliance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

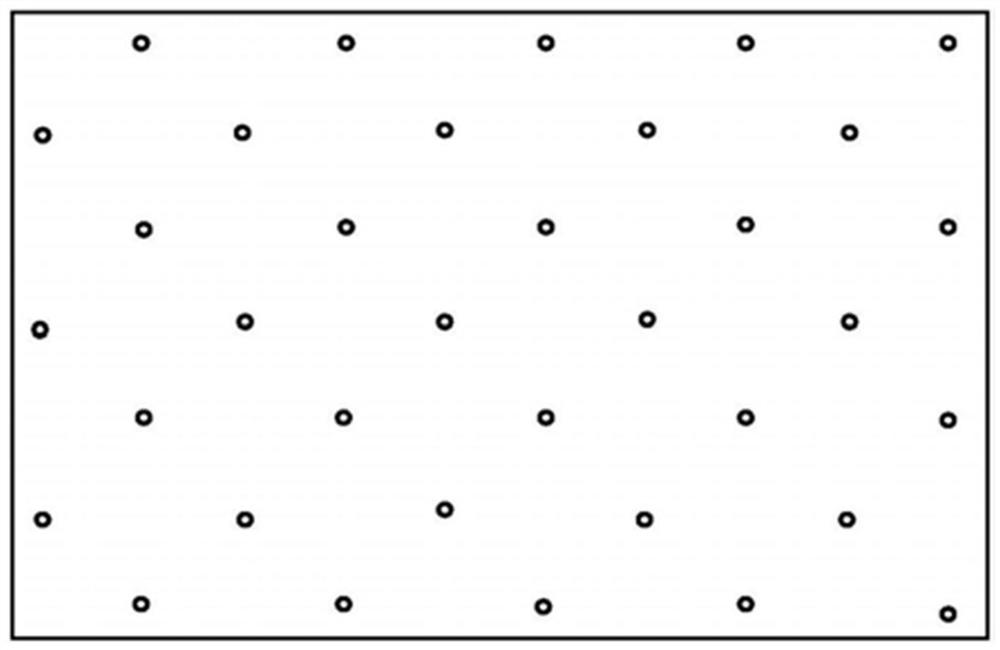

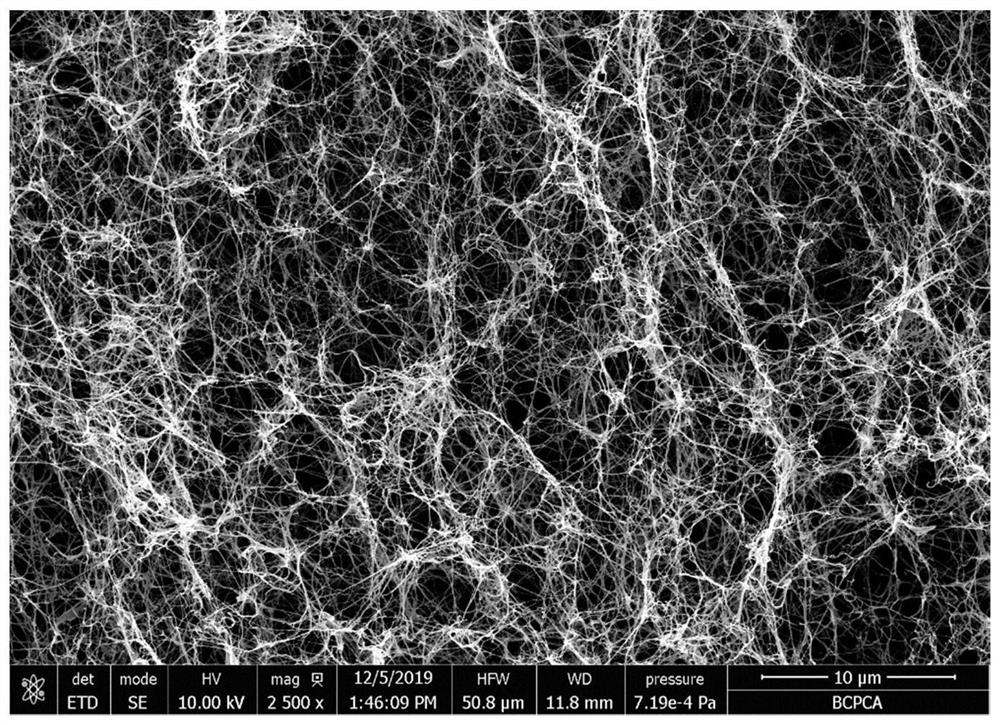

[0037] In view of the problems existing in breast patches in the prior art, the present invention first provides a bacterial cellulose film for preparing breast patches, and the preparation method of the bacterial cellulose film includes the following steps: preparing bacterial fibers by rotary fermentation In the process of fermentation, macromolecular substances with a particle size of 10-500 μm are sprayed onto the bacterial cellulose film, so that the macromolecular substances are distributed in the bacterial cellulose film.

[0038] The bacterial cellulose membrane has good compatibility with the human body, but the pore size of the surface of the bacterial cellulose membrane prepared by the existing method is usually micron, and cells cannot ideally grow on its surface. The addition of the above substances in the process of the plain film is conducive to the formation of certain gaps between the bacterial cellulose films of different layers, which is conducive to the grow...

Embodiment 1

[0068] The present embodiment relates to a method for preparing a breast patch, comprising the following steps:

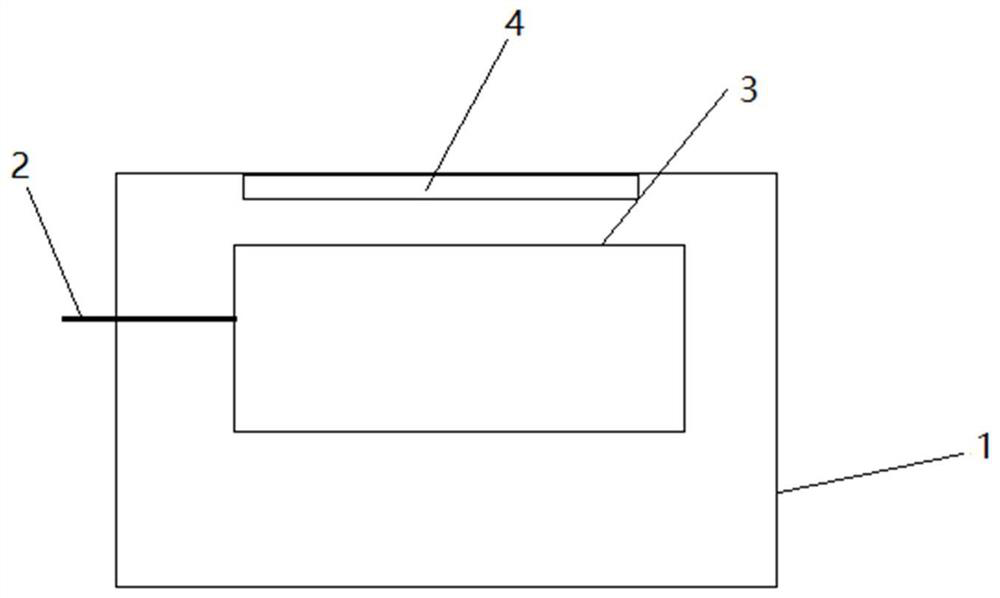

[0069] 1) To the rotary fermenter (its schematic diagram is as figure 1 ) in the tank body 1, add a fermentation medium, to its height and the surface of the bacterial cellulose film formation frame 2; , yeast extract 2.5g, citric acid 0.5g, disodium hydrogen phosphate 1g, dipotassium hydrogen phosphate 0.5g and the balance of distilled water;

[0070] 2) by activating the Acetobacter xylinum producing cellulose film to obtain an activated bacterial classification, the activated bacterial classification is expanded and cultivated to obtain a seed liquid, the seed liquid is inoculated into a fermentation medium and fermented to obtain a bacterial cellulose fermentation liquid, which is fermented for 5 days. Then, a bacterial cellulose film is formed on the surface of the bacterial cellulose forming frame;

[0071] 3) Rotate the rotating shaft, make the bacterial c...

Embodiment 2

[0083] The present embodiment relates to a method for preparing a breast patch, comprising the following steps:

[0084] 1) To the rotary fermenter (its schematic diagram is as figure 1 ), add the fermentation medium to its height and the surface of the bacterial cellulose membrane to form the frame; the formula of the fermentation medium is to contain in every 500mL: glucose 20g, maltose 15g, peptone 2.5g, yeast extract 2.5g , citric acid 0.5g, disodium hydrogen phosphate 1g, dipotassium hydrogen phosphate 0.5g and the balance of distilled water;

[0085] 2) activating the Acetobacter xylinum producing cellulose film, obtaining activated bacterial classification, expanding the activated bacterial classification to obtain seed liquid, inoculating the seed liquid into the fermentation medium and fermenting to obtain bacterial cellulose fermentation liquid, fermenting through 6 days Then, a bacterial cellulose film is formed on the surface of the bacterial cellulose forming fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| suture strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com