Compressed air energy storage system coupled and integrated with deep cooling air separation device

A technology of compressed air energy storage and compressed air, which is applied to pump devices, cold treatment separation, refrigeration and liquefaction, etc. It can solve the problems of increasing the cost of power generation and power supply, improve power generation efficiency, reduce design margins and equipment investment, and reduce consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

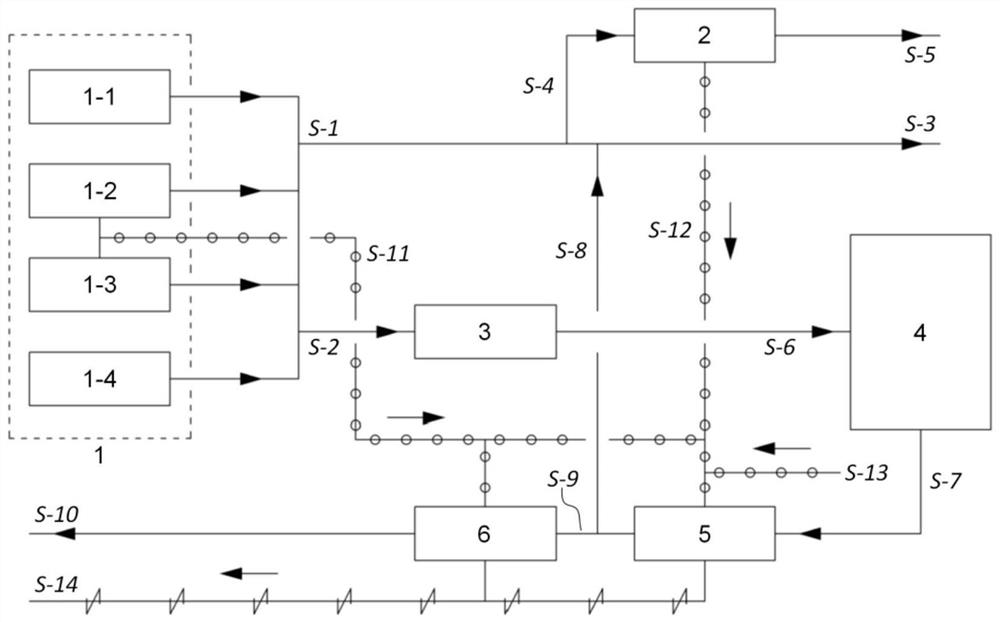

Embodiment 1

[0016] Embodiment 1 is aimed at a certain petrochemical enterprise 100000Nm 3 / h (Oxygen / Liquid Oxygen Production) Cryogenic Air Separation Unit establishes a compressed air energy storage system coupled with it, using the attached figure 1 process shown. The total gas volume of the air separation unit is 500000Nm 3 / h air, where the air compressor drive motor power is 41.0MW, the output pressure is 0.70MPaG, the supercharger drive motor power is 23.0MW, and the output pressure is 2.50MPaG. The daily energy storage scale of the energy storage system is 8,000,000Nm 3 High pressure air, storage pressure 8.3MPaG.

[0017] The driving motors of the air compressor and the energy storage compressor in the energy storage device are 65.6MW and 74.0MW respectively, and they run for 10 hours a day during the period of low electricity consumption when the electricity price is relatively low (from 22:00 to 8:00 the next day, 0.28 yuan / kWh). The scale of the high pressure turbine is ...

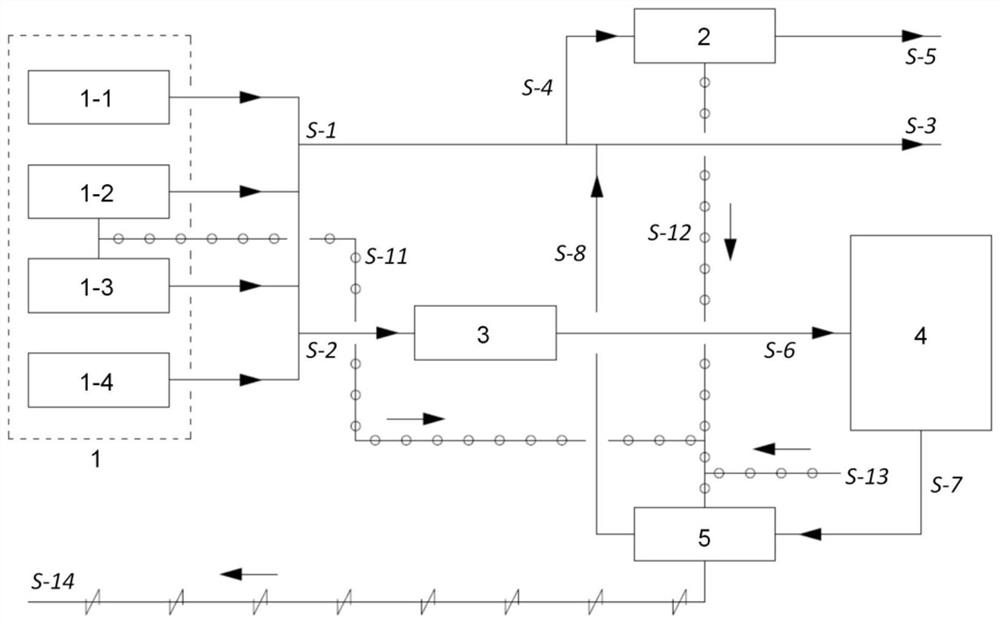

Embodiment 2

[0022]Embodiment 2 is aimed at a certain petrochemical enterprise 100000Nm 3 / h (Oxygen / Liquid Oxygen Production) Cryogenic Air Separation Unit establishes a compressed air energy storage system coupled with it, using the attached figure 2 process shown. The total gas volume of the air separation unit is 500000Nm 3 / h air, where the air compressor drive motor power is 41.0MW, the output pressure is 0.70MPaG, the supercharger drive motor power is 23.0MW, and the output pressure is 2.50MPaG. The daily energy storage scale of the energy storage system is 4,000,000Nm 3 High pressure air, storage pressure 8.3MPaG.

[0023] The driving motors of the air compressor and the energy storage compressor in the energy storage device are 32.8MW and 37.0MW respectively, and they run for 10 hours a day during the period of low electricity consumption when the electricity price is relatively low (from 22:00 to 8:00 the next day, 0.28 yuan / kWh). The scale of high pressure turbine is 5000...

Embodiment 3

[0028] Embodiment 3 is aimed at a certain petrochemical enterprise 100000Nm 3 / h (Oxygen / Liquid Oxygen Production) Cryogenic Air Separation Unit establishes a compressed air energy storage system coupled with it, using the attached figure 2 process shown. The total gas volume of the air separation unit is 500000Nm 3 / h air, where the air compressor drive motor power is 41.0MW, the output pressure is 0.70MPaG, the supercharger drive motor power is 23.0MW, and the output pressure is 2.50MPaG. The daily energy storage scale of the energy storage system is 3,200,000Nm 3 High pressure air, storage pressure 8.3MPaG.

[0029] The driving motors of the air compressor and the energy storage compressor in the energy storage device are 26.3MW and 29.6MW respectively, and they run for 10 hours a day during the period of low electricity consumption when the electricity price is relatively low (from 22:00 to 8:00 the next day, 0.28 yuan / kWh). The scale of high pressure turbine is 400...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap