Dry and wet rain area cooling tower capable of adjusting coverage area of dry area by utilizing water spraying potential energy of rain area

A covering area and cooling tower technology, applied in the direction of water shower coolers, lighting and heating equipment, engines, etc., can solve the problems of increasing air intake resistance, reducing the ventilation volume of the whole tower, and uneven radial distribution of the flow field of the cooling tower , to improve cooling efficiency, reduce ventilation resistance, and enhance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

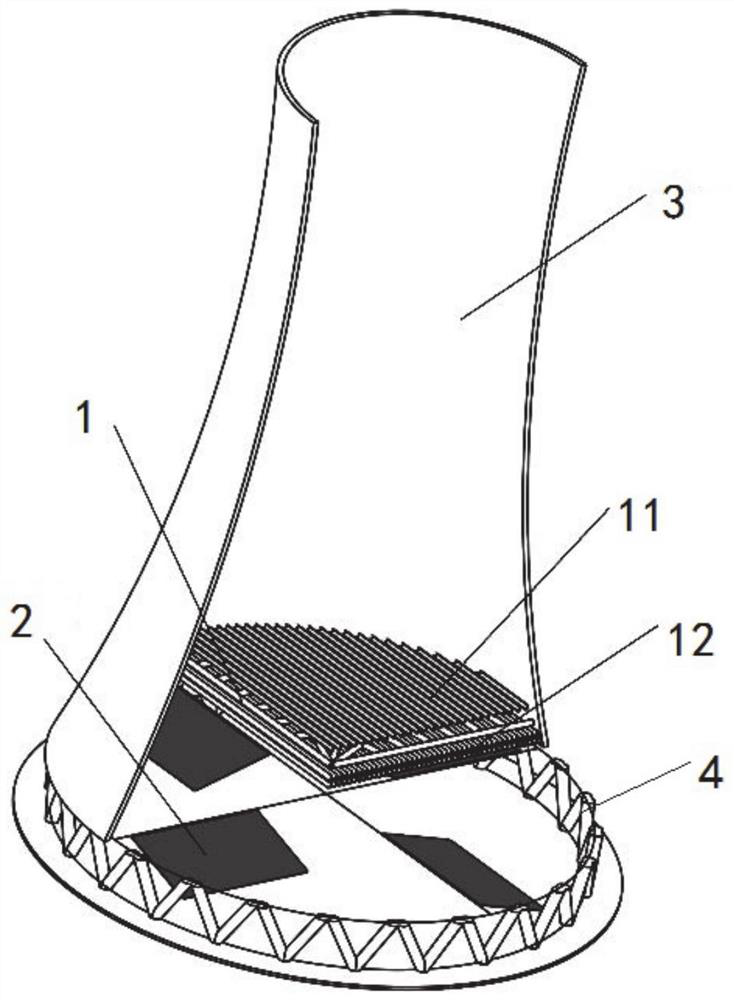

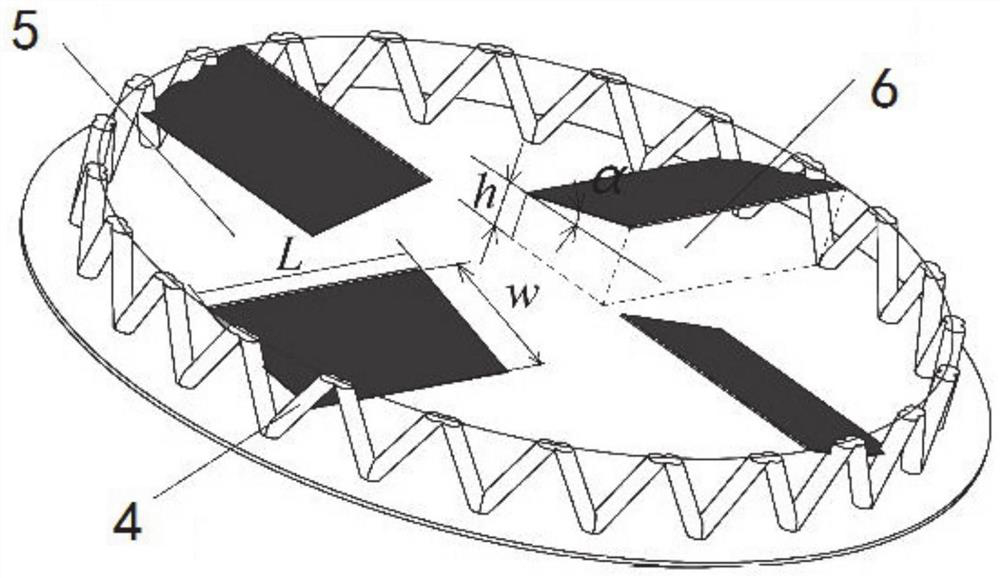

[0035] Such as Figure 1-4 As shown, the cooling tower in the dry and wet rain area is used to adjust the coverage area of the dry area by using the water potential energy of the rain area. One end of the splitter plate is located on the tower wall 3 of the cooling tower, and the other end points to the center of the radial section of the cooling tower. All the splitter plates are rotationally symmetrical about the center of the radial section of the cooling tower.

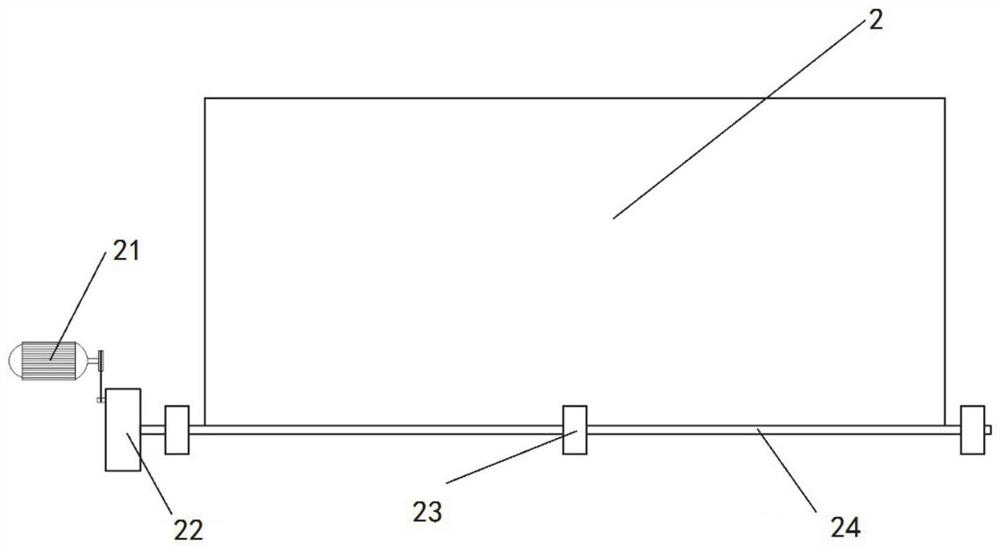

[0036] The cooling tower is a natural ventilation counter-flow wet cooling tower with dry and wet rain areas, and its conventional structure includes a water eliminator 11 at the top of the water distribution system 1, a filler 12 at the bottom of the water distribution system 1, and a dry and wet rain area.

[0037] A conventional cooling tower with a rain zone adds a splitter plate 2 to form a dry and wet rain zone cooling tower in the rain zone, where the area covered by the splitter plate 2 is the dry zone 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com