Synthesis and application of alcohol amine with lengthened main carbon chain

An alcohol amine and carbon chain technology, applied in the production of cement grinding aids and chemical building materials, can solve problems such as the inability to obtain alcohol bases, and achieve the effect of good grinding aid effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

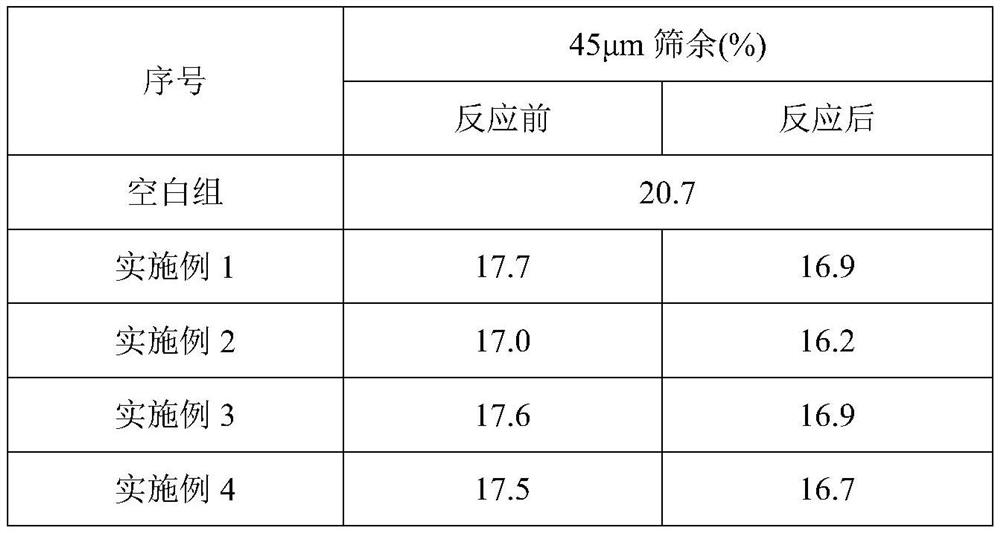

Embodiment 1

[0025] Add 14.9 g of triethanolamine to the flask, slowly add 3 ml of concentrated sulfuric acid while shaking to make the mixture uniform, and add 22.5 g of 36% hydrobromic acid into the dropping funnel. Then heat the reaction bottle to 100°C, react for 50 minutes, and then cool and distill. Then add 5ml of N-methylpyrrolidone, heat to 160°C and keep the temperature, slowly add potassium ferrocyanide solution, react for 60 minutes, then cool and distill. Finally, add 5 ml of 80% sulfuric acid aqueous solution, heat to reflux, and add lithium aluminum hydride, and distill after the reaction to obtain a novel alcohol amine with an extended main carbon chain.

Embodiment 2

[0027] Add 19.1 g of triisopropanolamine to the flask, slowly add 3 ml of concentrated sulfuric acid while shaking to make the mixture uniform, and add 22.5 g of 36% hydrobromic acid into the dropping funnel. Then heat the reaction bottle to 100°C, react for 50 minutes, and then cool and distill. Then add 5ml of N-methylpyrrolidone, heat to 150°C and keep the temperature, slowly add potassium ferrocyanide solution, react for 60 minutes, then cool and distill. Finally, add 5 ml of 80% sulfuric acid aqueous solution, heat to reflux, and add lithium aluminum hydride, and distill after the reaction to obtain a novel alcohol amine with an extended main carbon chain.

Embodiment 3

[0029] Add 16.3 g of diethanol monoisopropanolamine to the flask, slowly add 3 ml of concentrated sulfuric acid while shaking to make the mixture uniform, and add 22.5 g of 36% hydrobromic acid into the dropping funnel. Then heat the reaction bottle to 105°C, react for 50 minutes, and then cool and distill. Then add 5ml of N-methylpyrrolidone, heat to 170°C and keep the temperature, slowly add potassium ferrocyanide solution, react for 60 minutes, then cool and distill. Finally, add 5 ml of 80% sulfuric acid aqueous solution, heat to reflux, and add lithium aluminum hydride, and distill after the reaction to obtain a novel alcohol amine with an extended main carbon chain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com