Preparation method of canna edulis RS3 resistant starch and application thereof in functional foods and anti-Parkinson drugs

A technology of resistant starch and canna, which is applied in canna RS3 resistant starch and its application in functional food and anti-Parkinson drugs, can solve the problem of less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

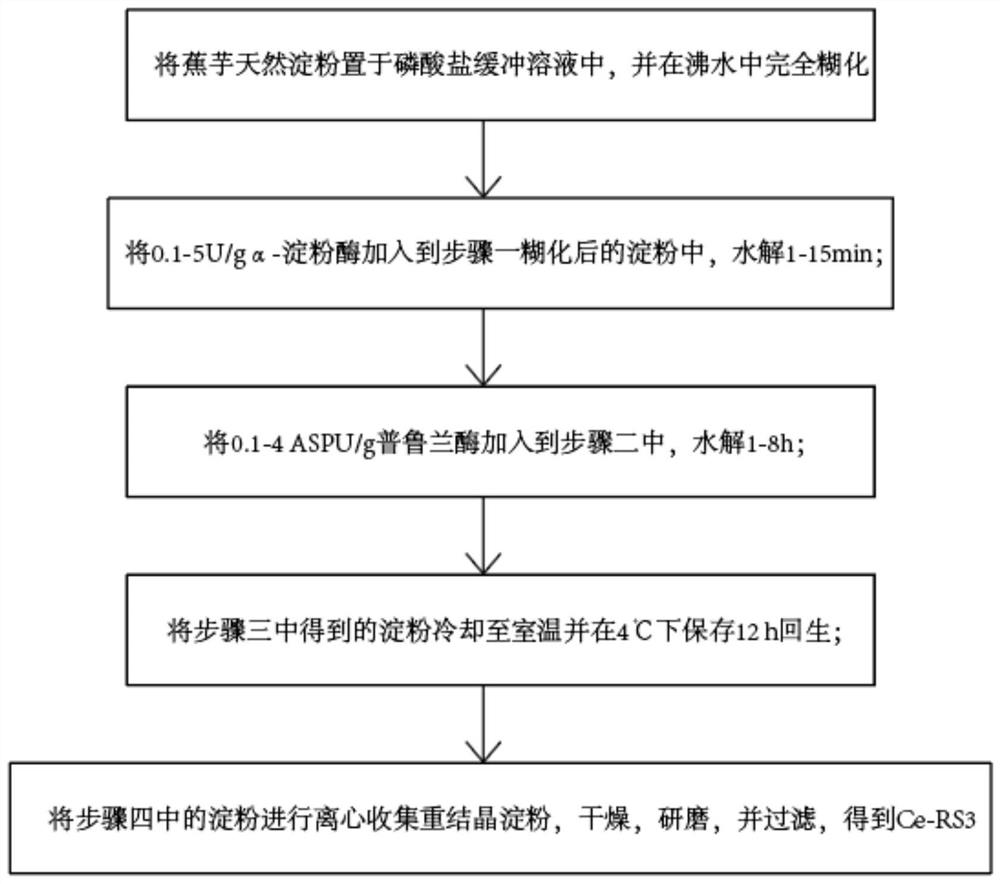

[0048] The invention discloses a preparation method of canna RS3 resistant starch, such as figure 1 shown, including the following steps:

[0049] Step 1. Canna taro natural starch is placed in phosphate buffer solution, and gelatinizes completely in boiling water;

[0050] Step 2. Add 0.1-5U / g α-amylase to the gelatinized starch in step 1, and hydrolyze for 1-15min;

[0051] Step 3. Add 0.1-4ASPU / g pullulanase to step 2, and hydrolyze for 1-8h;

[0052] Step 4. The starch obtained in step 3 is cooled to room temperature and stored at 4° C. for 12 hours to regenerate;

[0053] Step 5. Centrifuge the starch in step 4 to collect recrystallized starch, dry, grind, and filter to obtain Ce-RS3.

Embodiment 1

[0054] Embodiment 1 A kind of preparation method of canna taro RS3 resistant starch

[0055] Material:

[0056]Plantain natural starch was obtained from Guizhou Yilitai Biotechnology Co., Ltd. Pullulanase (1000ASPU / ml) was purchased from Novozymes Investment Co., Ltd. (Beijing, China). High-temperature α-amylase (10000 U / g) was purchased from Solarbio Co., Ltd. (Beijing, China). Potato amylose standard, amyl glucosidase, and porcine pancreatic alpha-amylase were provided by Sigma, Inc. (St. Louis, MO, USA). The D-glucose assay kit was obtained from Megazyme International Limited (Wicklow, Ireland). Deionized water was purified using a Milli-Q system (milipore, MA, USA).

[0057] Canna RS3 preparation:

[0058] 150g canna native starch was placed in 1000ml phosphate buffer solution (pH5.0), and completely gelatinized in boiling water for 20min. After that, add high-temperature α-amylase, stir at 200 rpm, adjust the cooked starch to 60°C, adjust the pH to 5.0, and then imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com