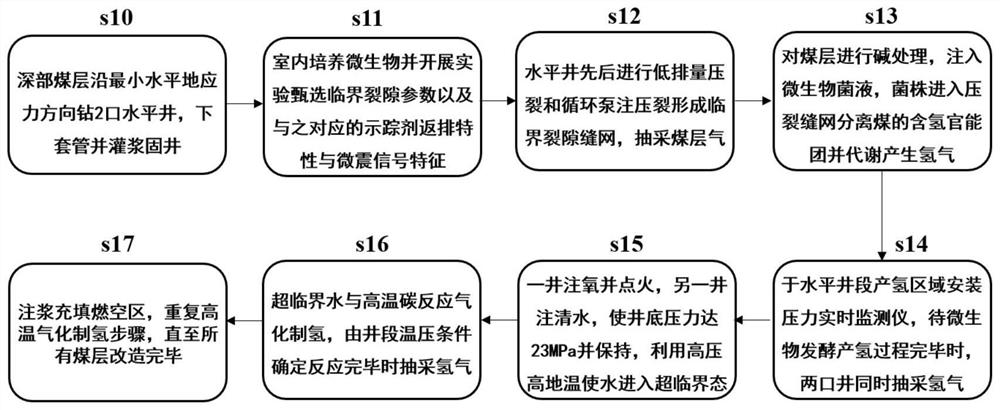

A bio-high temperature gasification combined mining method for hydrogen production from coal

A coal, high temperature technology, applied in coal gasification, ground mining, earthwork drilling and other directions, can solve the problems of large transportation costs, large discharge of waste water, waste gas and waste, and increased investment in the process of "three wastes", so as to improve the utilization rate, The effect of improving development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

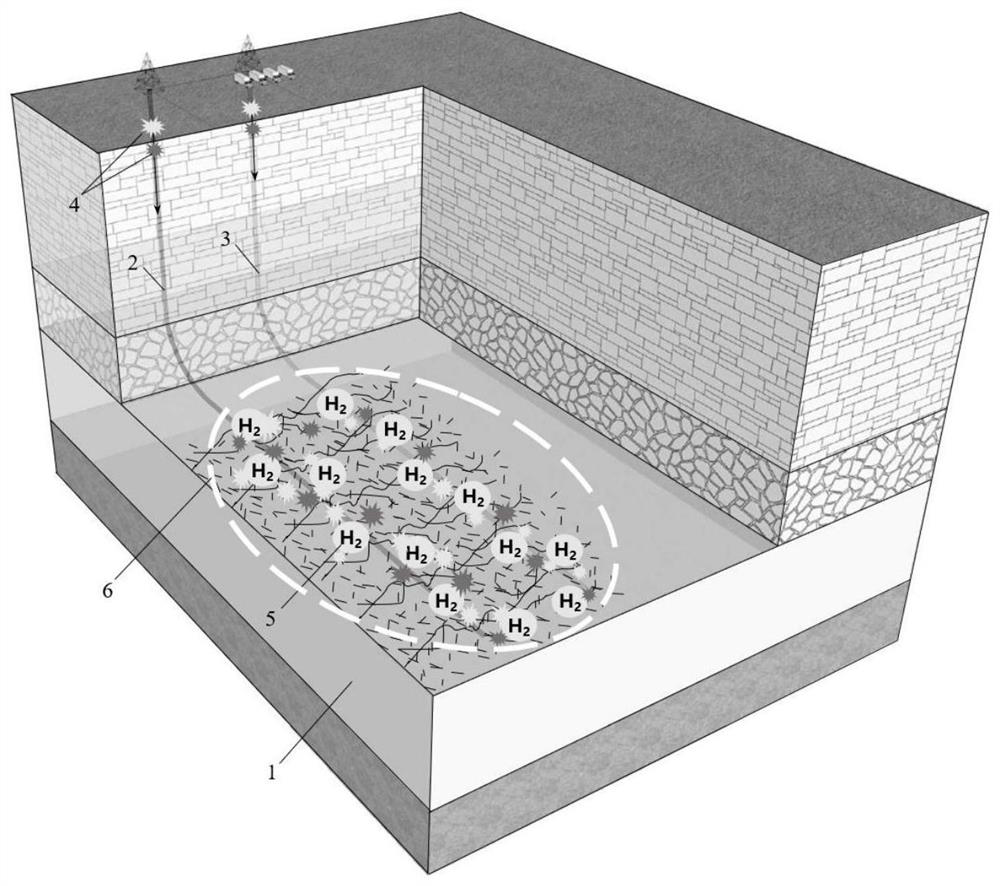

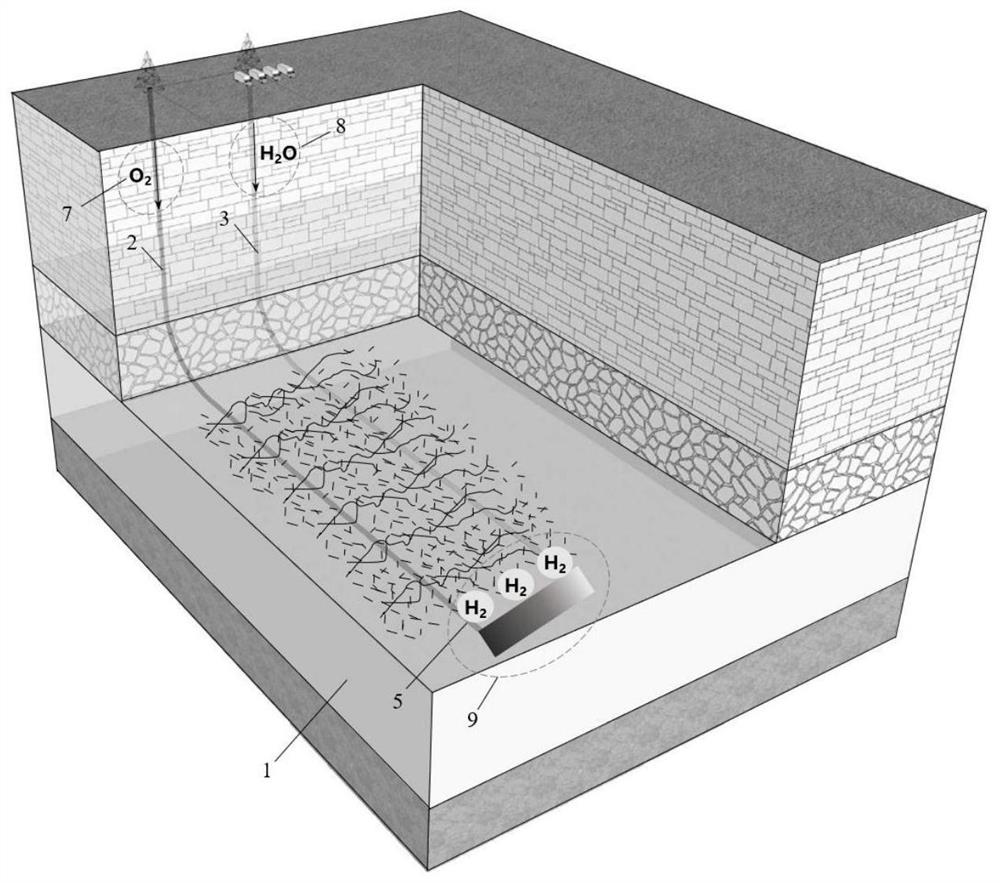

[0043] The technical solutions of the present invention will be described in detail below in conjunction with the drawings and specific implementations, and it should be understood that these implementations are only for illustration.

[0044] The coal seam is dense and has poor permeability, the original specific surface area of the coal body is small, and the sufficiency and uniformity of microbial diffusion are low, so the contact area between the coal-based hydrogen-producing microbial liquid and the coal body is small, and the exposure of biodegradable organic matter is relatively small. The microbes are small, and the effective nutrients supplied by the microorganisms to accept the unit coal body are insufficient, which greatly restricts the anaerobic fermentation rate of the coal-based hydrogen-producing microorganisms in the coal seam. The problem of contact area.

[0045] The bio-high-temperature gasification combined mining of coal hydrogen production belongs to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com