Surface treatment solution composition containing trivalent chromium and inorganic compound, and method for manufacturing hot dip galvanized steel sheet surface-treated using same

A hot-dip galvanized steel sheet and surface treatment technology, which is applied in the field of hot-dip galvanized steel sheet and surface treatment solution composition, can solve the problems of discoloration and discomfort, and achieve excellent weldability and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

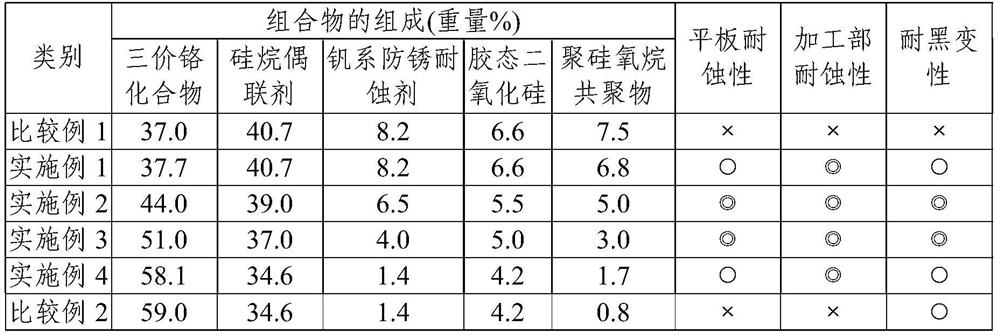

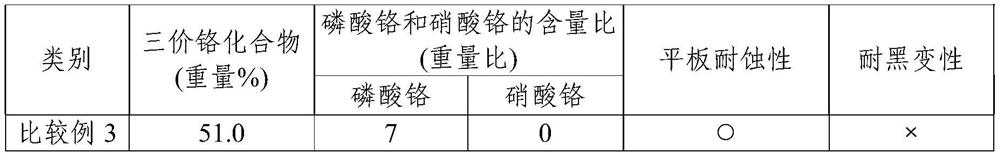

[0057] 1. Changes in physical properties depending on the content of trivalent chromium compounds

[0058] In order to test the changes in the physical properties of the contents of each component of the surface treatment solution composition according to the present invention, the following surface treatment solution composition is prepared: the surface treatment solution composition comprises a trivalent chromium compound, a vanadium series antirust and corrosion resistant agent, Colloidal silica, silane coupling agent, polysiloxane copolymer and water, wherein, the trivalent chromium compound is chromium nitrate and chromium phosphate, and the vanadium series antirust and corrosion resistant agent is vanadium acetylacetonate, so The colloidal silicon dioxide is Ludox HAS (snowtex-O), and the silane coupling agent is a mixture of tetraethyl orthosilicate and 3-glycidoxypropyltrimethoxysilane in a weight ratio of 1:1. A mixture, the polysiloxane copolymer is a polysiloxane co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com