Treatment method of positive electrode active substance waste product of lithium ion secondary battery

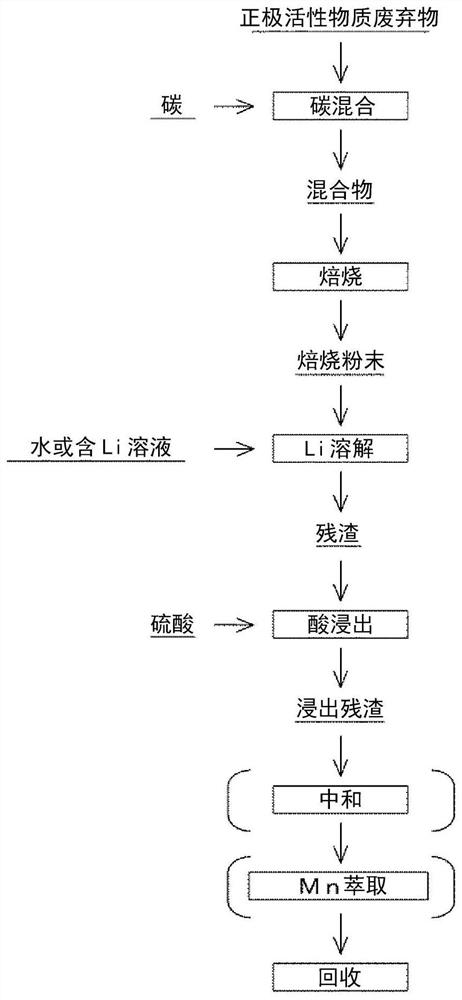

A positive electrode active material and treatment method technology, applied in the direction of battery electrodes, solid waste removal, lithium oxide;/hydroxide, etc., can solve problems such as complex process, poor treatment efficiency, and increased treatment or equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

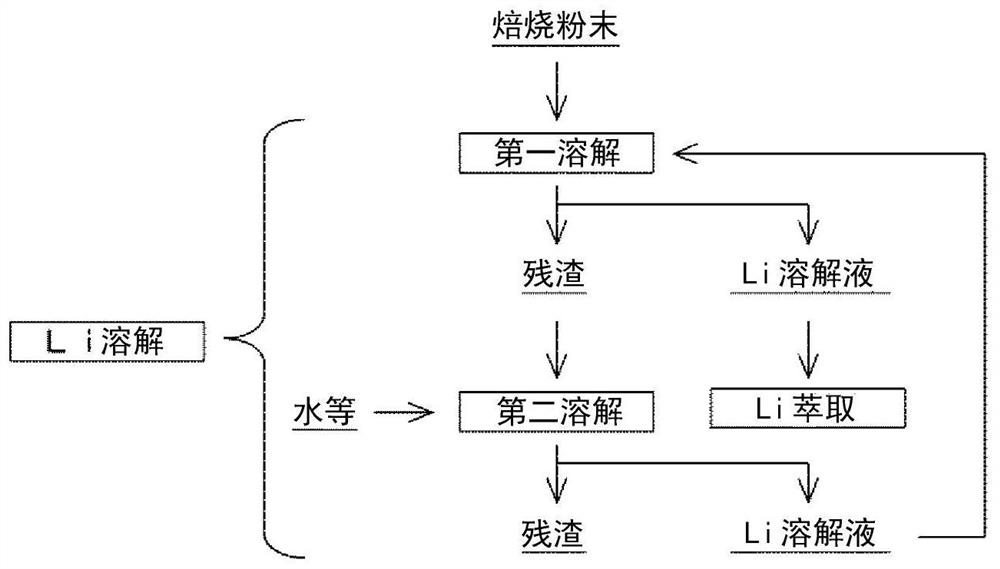

Method used

Image

Examples

Embodiment

[0105] Next, the above-mentioned treatment method of positive electrode active material waste was experimentally implemented and its effect was confirmed, so it will be described below. However, the description here is for the purpose of illustration only, and is not intended to be limited thereto.

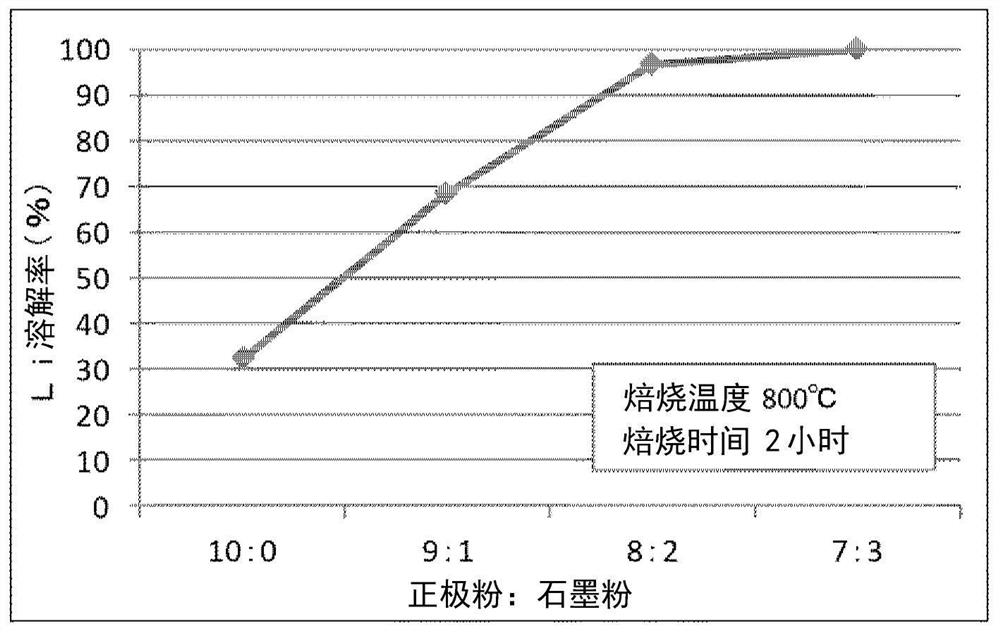

[0106] The powder of the positive electrode active material containing cobalt, nickel, manganese, and lithium was mixed with varying ratios of graphite powder as carbon, and the mixture was fired at different temperatures over 2 hours. The calcined powder obtained after the calcining was added to water to dissolve lithium in the calcined powder in the water. The results of these are shown in image 3 and 4 .

[0107] according to image 3 It can be seen that the dissolution rate of lithium is greatly improved when more carbon is mixed than the positive electrode active material powder:carbon ratio of 9:1. In particular, when the mixing ratio of the positive electrode active m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com