Frozen tender fish ball based on endogenous enzyme activity regulation and processing method thereof

A processing method and endogenous enzyme technology, which are applied in the field of food processing, can solve the problems of surimi products, such as large impact, reduced tenderness, and reduced gel strength of surimi products, so as to solve the problem of loose structure, improve tenderness, The effect of reducing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

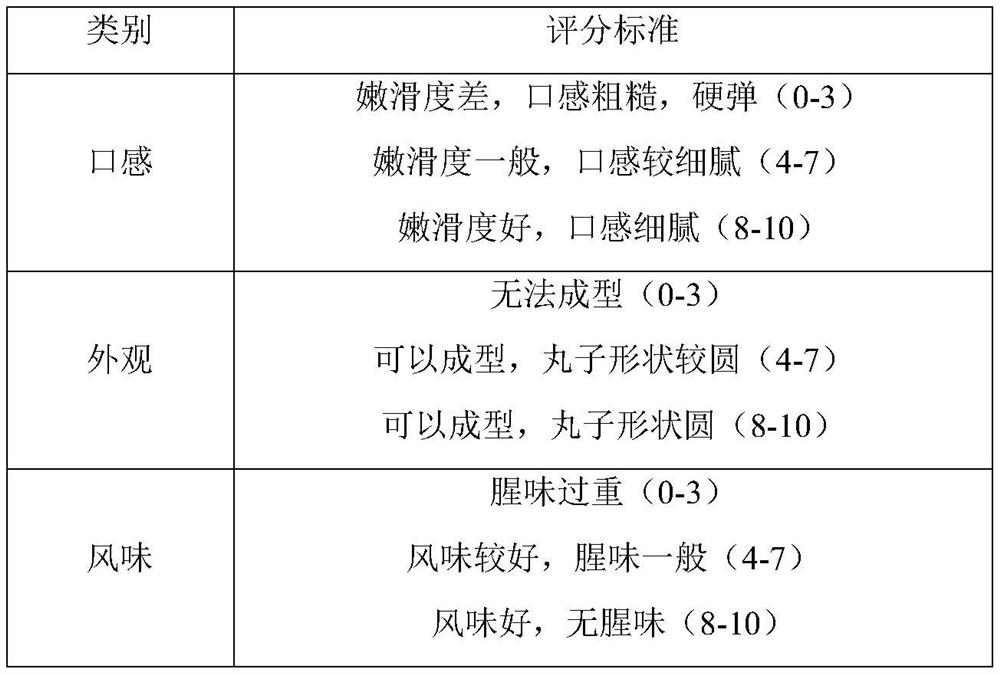

Examples

Embodiment 1

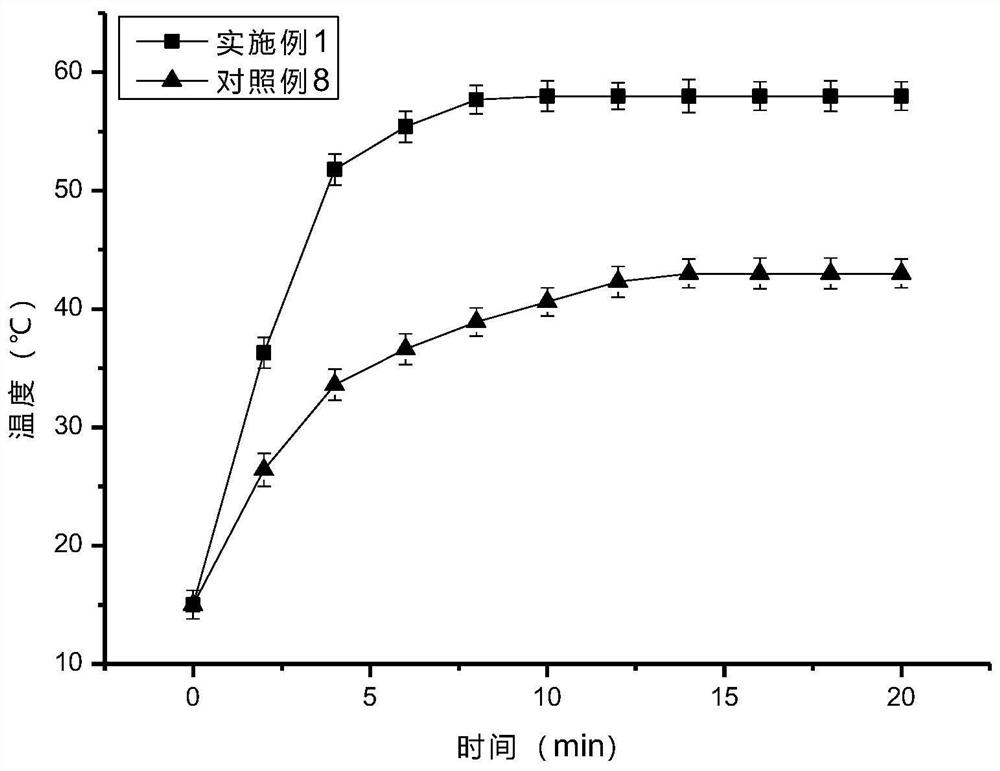

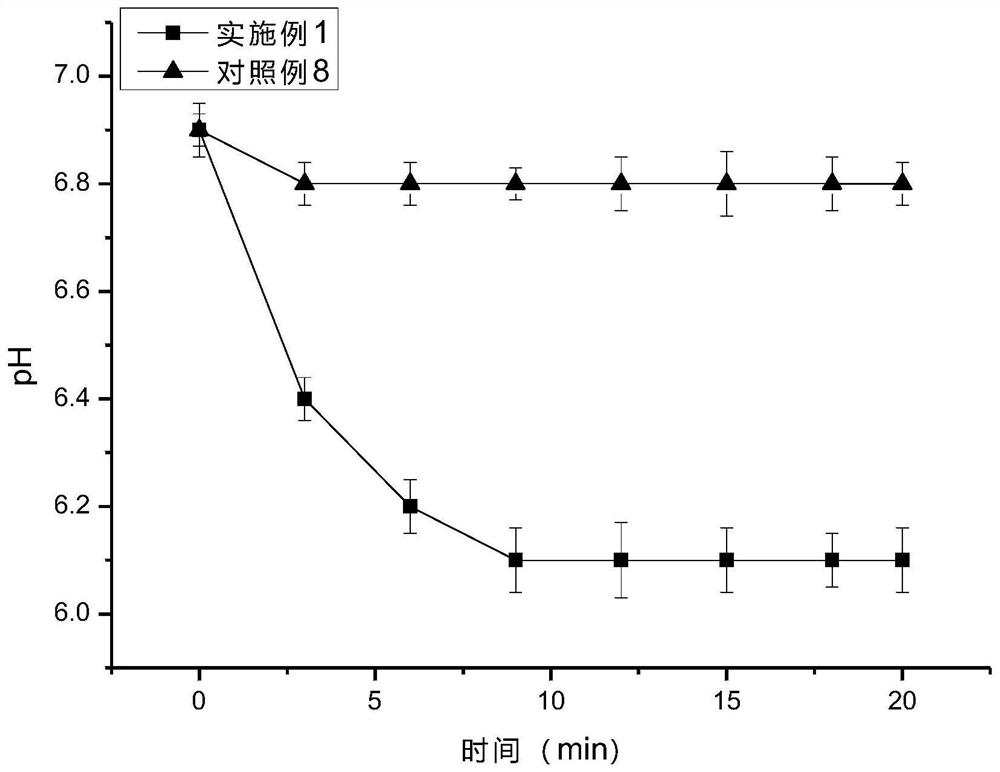

[0049] A processing method based on the regulation of endogenous enzyme activity for frozen tender fish balls, comprising the steps of:

[0050] (1) Thawing: thaw the frozen surimi at 4°C and 85% humidity for 16 hours, so that the surface temperature of the surimi is below 8°C, and the central temperature of the surimi is -3°C, and the thawed surimi is obtained;

[0051] (2) Empty chopping: Put 40 parts of thawed surimi into an ultra-high-speed vacuum chopping machine, add 0.3 parts of sodium hexametaphosphate at the same time, chop and mix for 5 minutes under the condition of 1500r / min, so that the surimi has no hard particles , slightly viscous, and the temperature does not exceed 2°C; the slurry after empty chopping is obtained;

[0052] (3) Salt chopping: Add 1.5 parts of table salt to the slurry after empty chopping and mix evenly, then chop and mix at a speed of 4200r / min for 2min, then add 6 parts of ice water, chop and mix at 4000r / min for 3min, the slurry The tempera...

Embodiment 2

[0059] Adjust the gel in step (6) of Example 1 to "gel in a 65°C water bath for 5.5 minutes so that the central temperature reaches 52°C and the pH reaches 6.5, then in a 55°C water bath, the pH reaches 6.1 and the gel takes 14.5 minutes", other and Embodiment 1 is consistent, obtains frozen tender fish balls.

Embodiment 3

[0061] Adjust the gel in step (6) of Example 1 to "gel in a 70°C water bath for 2.5 minutes so that the central temperature reaches 52°C and the pH reaches 6.3, then in a 55°C water bath, the pH reaches 6.1 and the gel takes 16.5 minutes", other and Embodiment 1 is consistent, obtains frozen tender fish balls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com