Food leavening agent based on 3D printing as well as preparation method and application of food leavening agent

A 3D printing and food fermentation technology, applied in the field of bioengineering, can solve the problems of low efficiency, non-standard safety, and poor versatility, and achieve the effects of increased mechanical strength, simple preparation process, and long use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

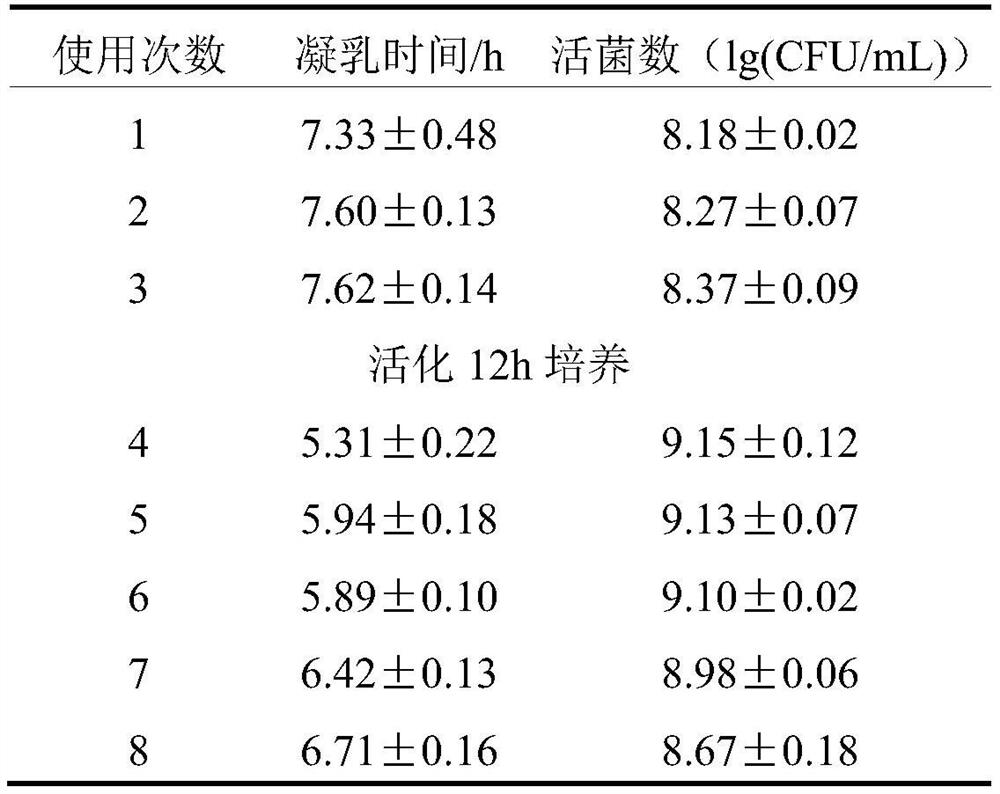

Examples

Embodiment 1

[0042] Weigh polyether (60g, 12600g / mol) in N 2 It was dissolved in 550 mL of dichloromethane under protection, and the mixture was stirred at 30° C., and after complete dissolution, 0.6 mL of dibutyltin dilaurate was added. 3.5 mL of isocyanoethyl methacrylate was diluted in 50 mL of dichloromethane and added dropwise to the reaction mixture. make the reaction at N 2 , stirring at 30 °C for 2 days, then quenched by adding 60 mL of methanol. After the mixture was concentrated by rotary evaporation, it was added to 2000 mL of diethyl ether for precipitation. The precipitated mixture was finally washed twice in diethyl ether, and then dried under vacuum to obtain a modified polyether.

[0043] Weigh 3 g of the modified polyether and dissolve it in 7 mL of sterile pure water, cool the resulting mixture at 4 °C and periodically vortex mix it, after it is completely dissolved, mix the mixture with 2-hydroxy-2-methyl- 1-phenylacetone (0.1% by volume with sterile pure water) and ...

Embodiment 2

[0048] Weigh polyether (60g, 12600g / mol) in N 2 It was dissolved in 550 mL of dichloromethane under protection, and the mixture was stirred at 30° C., and after complete dissolution, 0.6 mL of dibutyltin dilaurate was added. 3.5 mL of isocyanoethyl methacrylate was diluted in 50 mL of dichloromethane and added dropwise to the reaction mixture. make the reaction at N 2 , stirring at 30 °C for 2 days, then quenched by adding 60 mL of methanol. After the mixture was concentrated by rotary evaporation, it was added to 2000 mL of diethyl ether for precipitation. The precipitated mixture was finally washed twice in diethyl ether, and then dried under vacuum to obtain a modified polyether.

[0049] Weigh 3 g of the modified polyether and dissolve it in 7 mL of sterile pure water, cool the resulting mixture at 4 °C and periodically vortex mix it, after it is completely dissolved, mix the mixture with 2-hydroxy-2-methyl- 1-phenylacetone (0.1% by volume to sterile pure water) and 0....

Embodiment 3

[0053] Weigh polyether (60g, 12600g / mol) in N 2 It was dissolved in 550 mL of dichloromethane under protection, and the mixture was stirred at 30° C., and after complete dissolution, 0.6 mL of dibutyltin dilaurate was added. 3.5 mL of isocyanoethyl methacrylate was diluted in 50 mL of dichloromethane and added dropwise to the reaction mixture. make the reaction at N 2 , stirring at 30 °C for 2 days, then quenched by adding 60 mL of methanol. After the mixture was concentrated by rotary evaporation, it was added to 2000 mL of diethyl ether for precipitation. The precipitated mixture was finally washed twice in diethyl ether, and then dried under vacuum to obtain a modified polyether.

[0054] Weigh 3 g of the modified polyether and dissolve it in 7 mL of sterile pure water, cool the resulting mixture at 4 °C and periodically vortex mix it, after it is completely dissolved, mix the mixture with 2-hydroxy-2-methyl- 1-Phenylacetone (0.1% by volume of sterile pure water) was mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com