Method for preparing CuPt alloy nanoparticles at room temperature

A technology of alloy nanoparticles and room temperature, applied in the direction of nanotechnology, can solve the problems of increasing the complexity of the preparation process, increasing energy consumption, etc., and achieve the effects of improving product purity, simplifying cleaning steps, and small product size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) Take deionized water as a solvent, configure a volume of 40 milliliters, a copper chloride solution with a concentration of 15 mmol / L and a volume of 5 milliliters, a concentration of 10 mmol / L of chloroplatinic acid, stir for 30 minutes until uniform , to obtain a mixed solution 1;

[0037] 2) Add a mass of 0.18 g of potassium chloride to the mixed solution 1, stir at room temperature for 10 minutes until uniform, add a volume of 5 ml of hydrochloric acid solution with a concentration of 0.1 mol / L, and continue stirring for 15 minutes to obtain a mixed solution 2;

[0038] 3) Add ascorbic acid with a volume of 12.5 ml and a concentration of 1.0 mol / L to the mixed solution 2, and stir and react at room temperature for 6 hours;

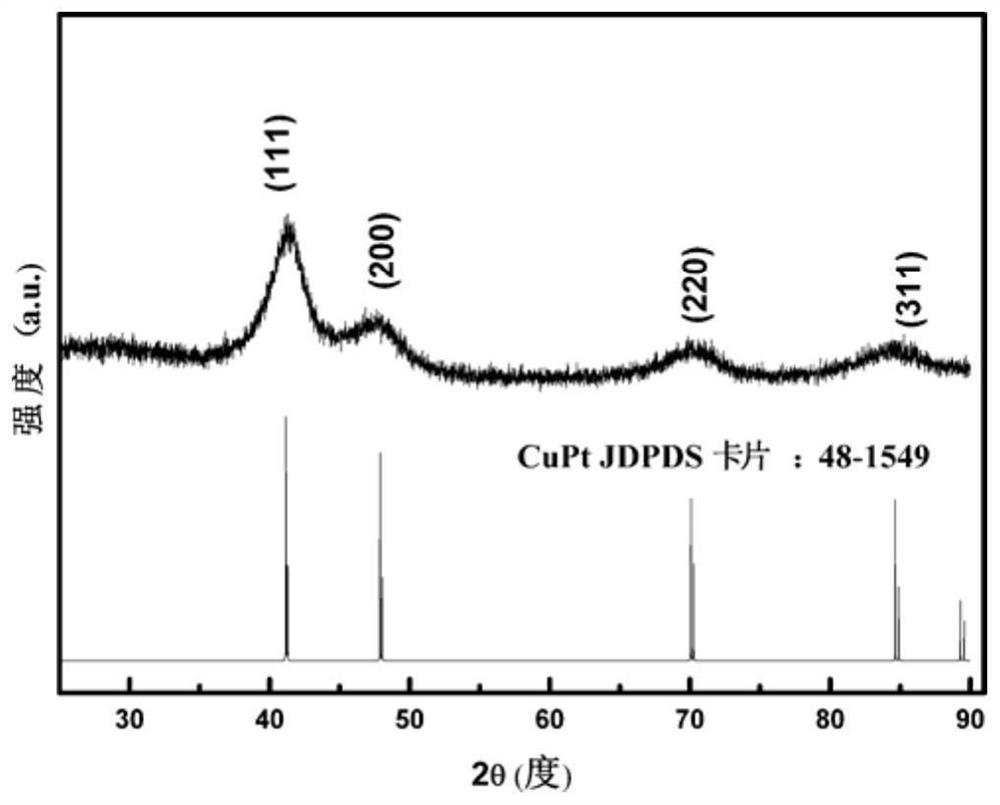

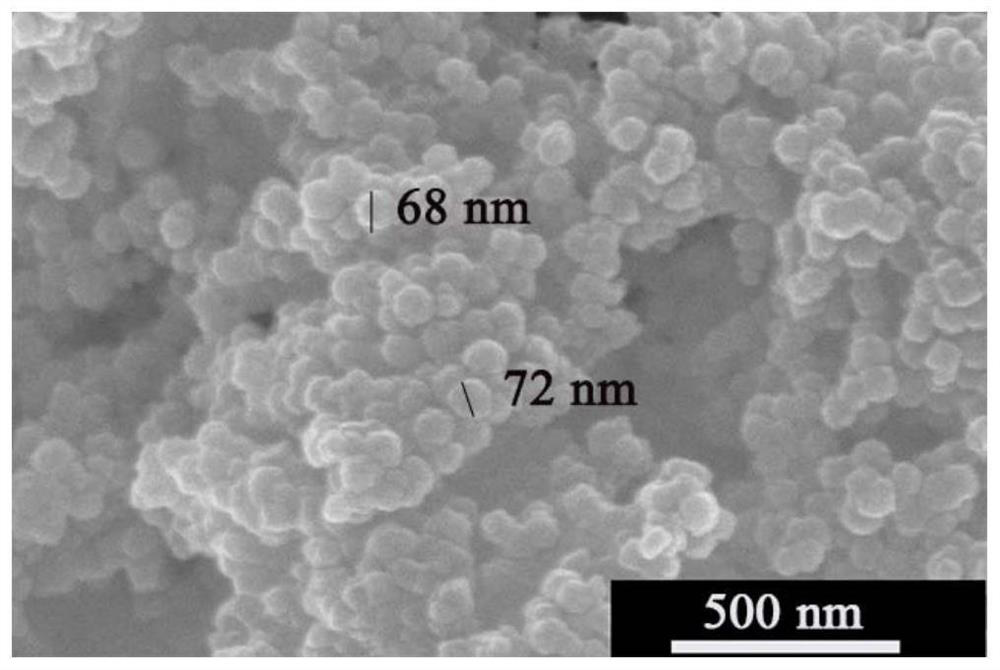

[0039] 4) The obtained product is separated by a centrifuge, firstly dispersed in deionized water for ultrasonication, and then secondly centrifuged, dispersed in ethanol for ultrasonication, centrifuged again to extract the sample powder, an...

Embodiment 2

[0043] 1) Take deionized water as a solvent, configure a volume of 40 milliliters, a copper chloride solution with a concentration of 18 mmol / liter and a volume of 5 milliliters, a concentration of chloroplatinic acid with a concentration of 10 mmol / liter, stir until uniform, and obtain mixed solution 1;

[0044] 2) Add a mass of 0.3 g of potassium chloride to the mixed solution 1, stir at room temperature for 5 minutes, add a volume of 2 ml of hydrochloric acid with a concentration of 0.15 mol / L, and continue stirring for 20 minutes to obtain a mixed solution 2;

[0045] 3) Add ascorbic acid with a volume of 12.5 ml and a concentration of 1.2 mol / L to the mixed solution 2, and stir and react at room temperature for 5 hours;

[0046] 4) The obtained product is separated with a centrifuge, firstly dispersed in deionized water and ultrasonically centrifuged for the second time, dispersed in ethanol and ultrasonically extracted, and centrifuged again to extract the sample powder,...

Embodiment 3

[0049] 1) With deionized water as a solvent, configure a volume of 35 milliliters, a copper chloride solution with a concentration of 16 mmol / L and a volume of 5 milliliters, a concentration of 10 mmol / L of chloroplatinic acid, stir for 10 minutes until uniform , to obtain a mixed solution 1;

[0050] 2) Add 0.315 g of potassium chloride into the mixed solution 1, stir at room temperature for 5 minutes, add 8 ml of HCl with a concentration of 0.1 mol / L, and continue stirring for 20 minutes to obtain the mixed solution 2;

[0051] 3) Add ascorbic acid with a volume of 12.5 ml and a concentration of 1.2 mol / L to the mixed solution 2, and stir and react at room temperature for 5 hours;

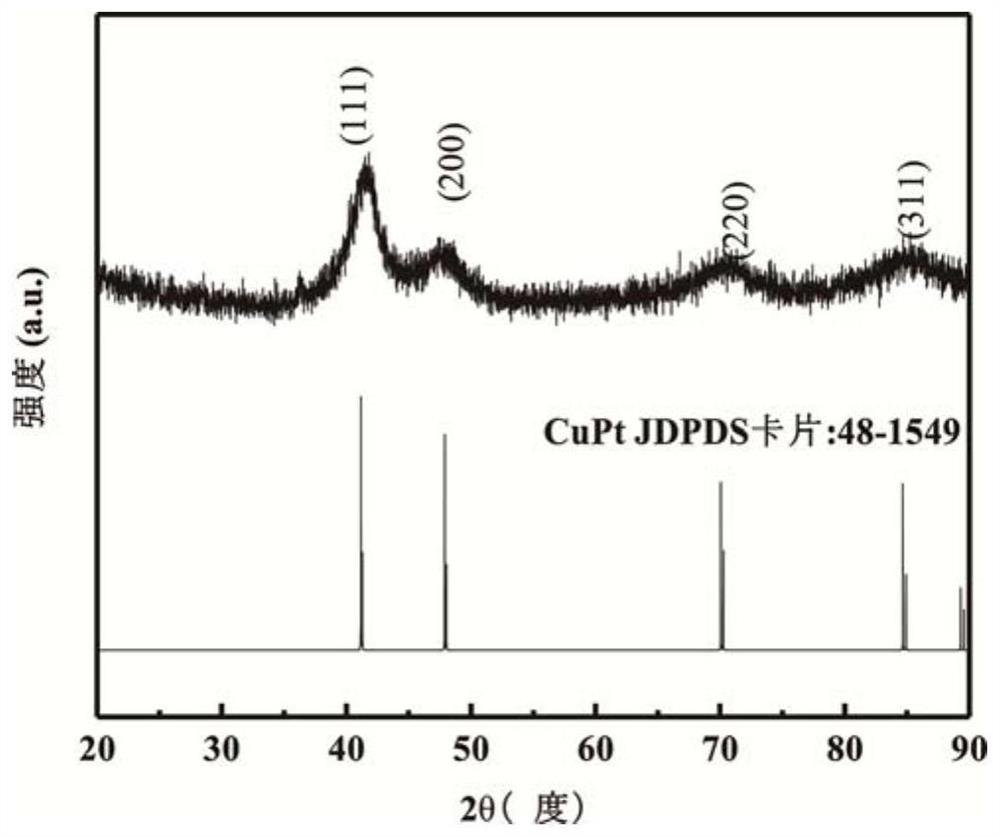

[0052] 4) The obtained product is separated with a centrifuge, first dispersed in deionized water and ultrasonically centrifuged for the second time, dispersed in ethanol for ultrasonication, and centrifuged again to extract the sample powder, and then dried in a blast drying oven at 50 degrees C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com