Mixed waste salt recovery process

A salt recovery and process technology, applied in the direction of alkali metal compounds, alkali metal sulfite/sulfite, alkali metal chloride, etc., can solve the problems of organic residues and affecting the purity of salt compound products, so as to improve the purity, Uniform heating and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The embodiment of the present application discloses a mixed waste salt recovery process.

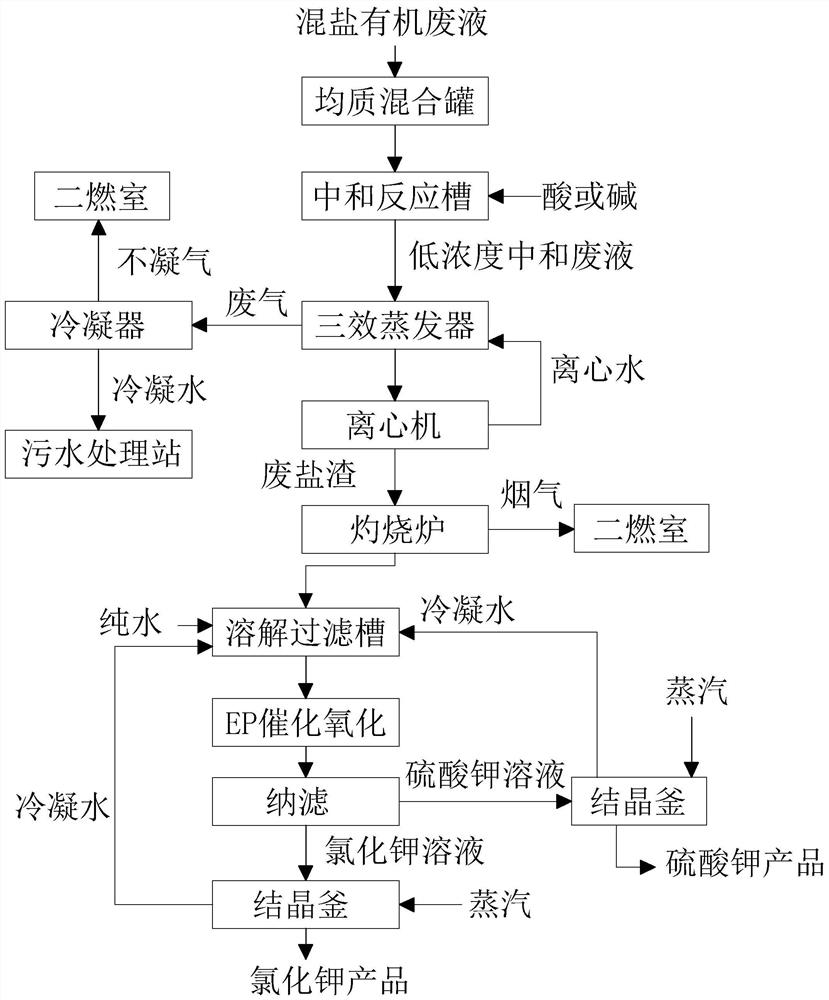

[0050] Such as figure 1 Shown, a kind of mixed waste salt recovery process, comprises sequential steps successively:

[0051] This application takes the recovery of potassium salt as an example, wherein the mixed salt organic waste liquid is an acidic solution.

[0052] S1: Acid-base neutralization, add the mixed salt organic waste liquid into the homogeneous mixing tank and mix evenly, then add the mixed salt organic waste liquid into the neutralization reaction tank, add potassium hydroxide into the neutralization reaction tank, and finally And the pH of the solution in the reaction tank is adjusted to be 7, and the neutralized waste liquid is obtained. If the mixed salt organic waste salt becomes alkaline, add sulfuric acid into the neutralization reaction tank.

[0053] S2: Drying and dehydration: Detect the concentration of the neutralization solution, the concentration is...

Embodiment 2

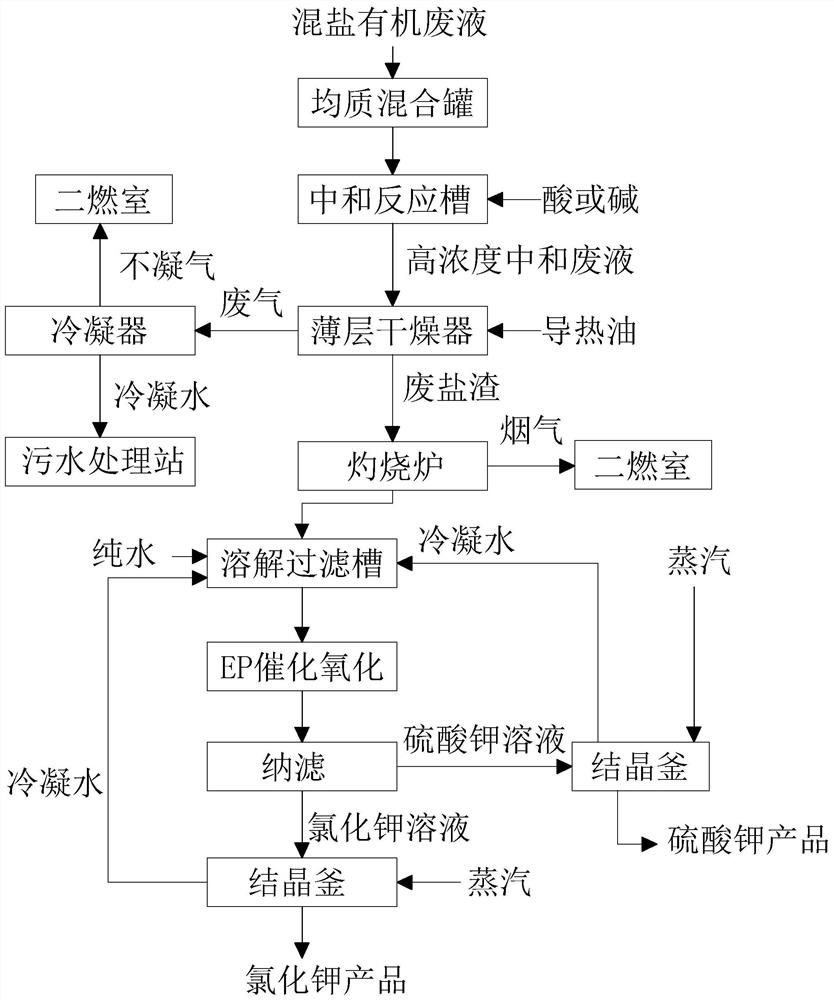

[0060] Such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that in step S2, the concentration of the neutralization solution is detected, and the concentration is between 10-15wt%, and the high-concentration neutralization waste liquid is directly sent to the thin layer for drying Dry in a container. The drying heat source comes from the heat-conducting oil furnace in the factory area, and the thin-layer dryer is in a negative pressure environment. The waste gas generated is condensed through the condenser, the condensed water is pumped to the sewage station of the factory area for treatment, and the non-condensable gas is sent to the secondary combustion chamber for incineration.

Embodiment 3

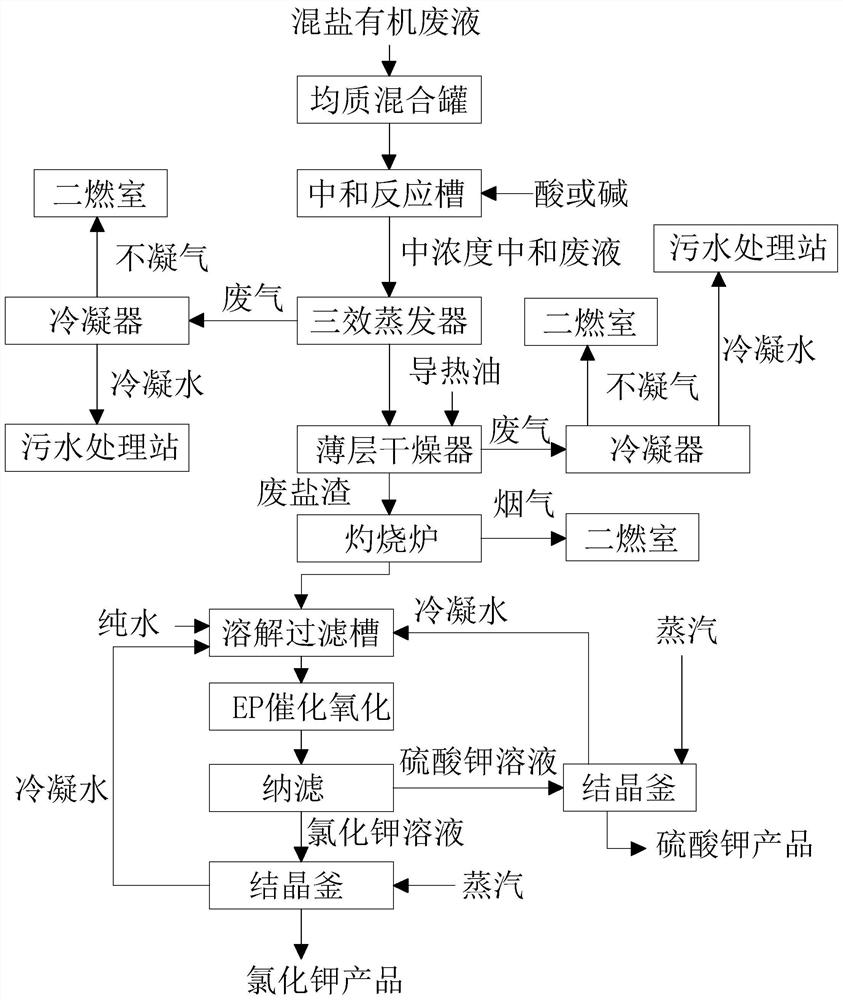

[0062] Such as image 3 As shown, the difference between embodiment 3 and embodiment 1 is that: in step S2, the concentration of the neutralization solution is detected, the concentration is between 5-10wt%, and the middle concentration neutralization waste liquid is added to the three-effect evaporator , and then the dope obtained by three-effect evaporation is sent to a thin-layer drier for drying. The drying heat source comes from the heat-conducting oil furnace in the factory area, and the thin-layer dryer is in a negative pressure environment. The waste gas generated is condensed through the condenser, the condensed water is pumped to the sewage station of the factory area for treatment, and the non-condensable gas is sent to the secondary combustion chamber for incineration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com