Device and method for enhancing aeration by utilizing hydraulic shearing and gas buoyancy

A hydraulic shearing and aeration technology, applied in chemical instruments and methods, water aeration, biological treatment devices, etc., can solve problems such as easy blockage of aeration system, low oxygenation efficiency, uneven aeration, etc., and achieve Accelerated oxygen transfer rate, long service life, and increased turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

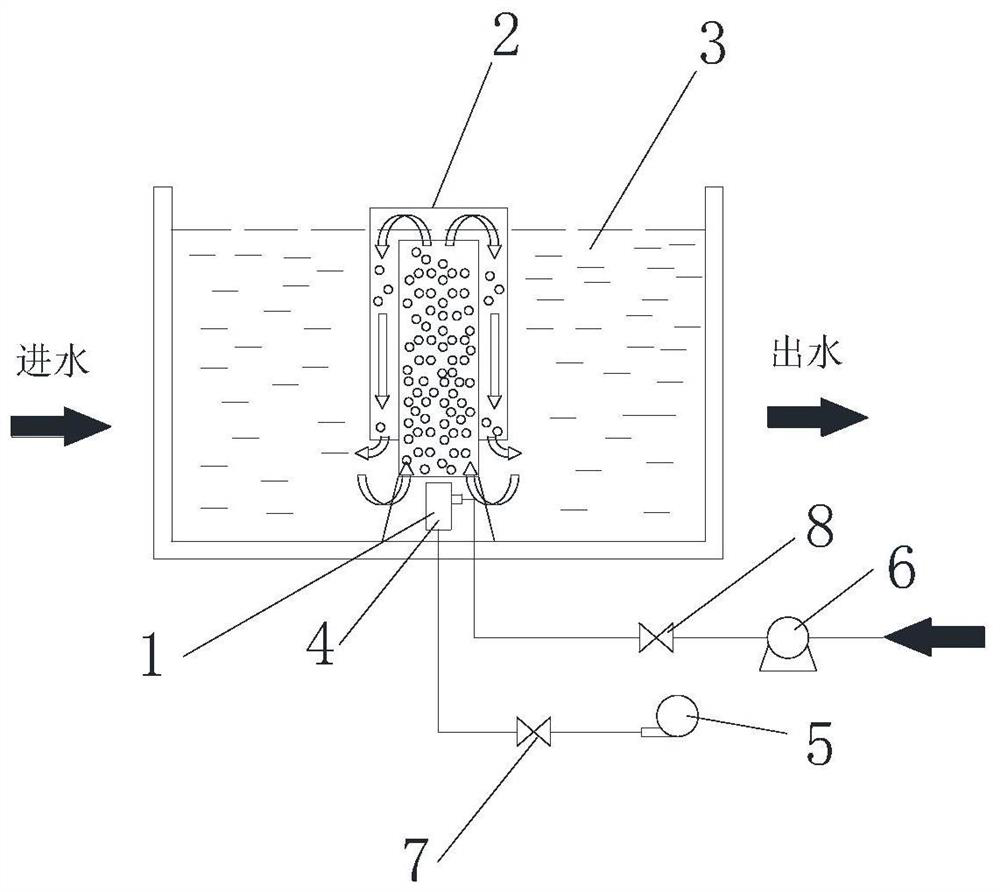

[0050] figure 1 It is the device of the present invention that uses hydraulic shear and gas buoyancy to generate fine bubbles to enhance aeration, and the device for enhancing aeration includes a bubble generating unit 1 and an airlift circulation unit 2 installed above the bubble generating unit 1, The bubble generation unit 1 includes an aeration core tube 4 arranged at the bottom of the aeration tank 3 and a blower 5 and a booster pump 6 that are connected to the aeration core tube 4 through pipelines and placed outside the aeration tank 3 .

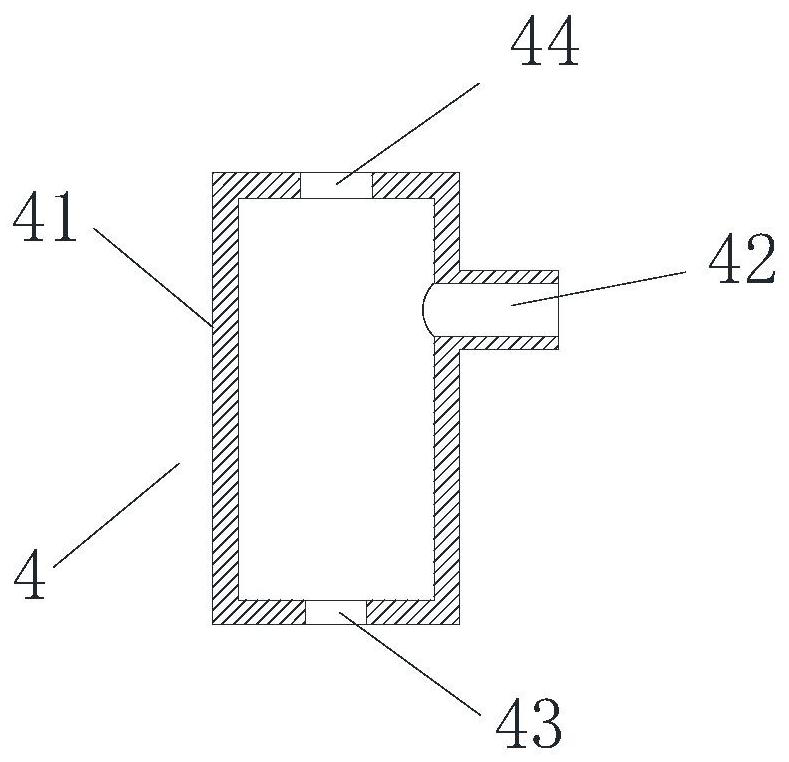

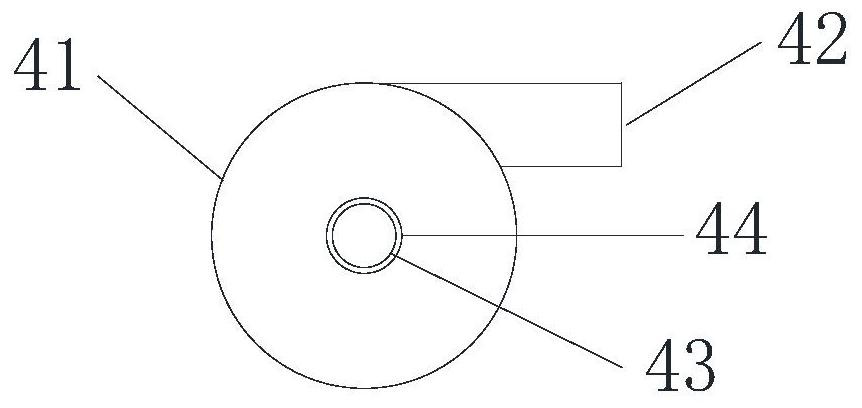

[0051] Wherein, the aeration core tube 4 is located at the center of the bottom of the airlift circulation unit 2, such as figure 2 and 3 As shown, the aeration core tube 4 includes a cylindrical swirl chamber segment 41, the interior of the swirl chamber segment 41 is a cavity structure, the side wall of the swirl chamber segment 41 is provided with a liquid inlet 42, and The direction of the liquid inlet 42 is tangent to the sid...

Embodiment 2

[0075] The device described in Example 1 is used to enhance aeration by utilizing hydraulic shear and gas buoyancy to generate fine bubbles, and transform the traditional blower aeration device. Such as Figure 6 and 7As shown, the width of the aeration tank 3 is 10m, the water depth is 5-6m, and the water flow direction is from left to right. Considering the reconstruction cost, energy consumption and hydraulic retention time, the original aeration head 11 in the first half of the aeration tank 3 is modified, and the original aeration head 11 is used in the second half.

[0076] According to calculations, the aeration-intensifying devices composed of the bubble generation unit 1 and the airlift circulation unit 2 are arranged in 5 rows along the width direction of the aeration tank 3, and each row is arranged with 4 pieces. The gap width between the adjacent airlift circulation units 2 is 1.5-2m, and the distance between the outermost airlift circulation unit 2 and the pool...

Embodiment 3

[0080] Adopt the device described in embodiment 1 to utilize hydraulic shearing and gas buoyancy to produce fine bubbles to strengthen aeration, such as Figure 8 As shown, the width of the aeration tank 3 is 10m, the length is 11m, and the water depth is 5-6m. In the aeration tank 3, four partition walls 9 are sequentially arranged along the length direction, and one end of the partition wall 9 It is connected to the inner wall on one side in the length direction of the aeration tank, and the other end is separated from the inner wall on the other side in the length direction of the aeration tank by 2m. The partition walls 9 are arranged crosswise to form a serpentine flow channel. The partition wall 9 divides the aeration tank 3 into five flow channels 10, the width of the first four flow channels 10 is 2m, and the width of the fifth flow channel 10 is 2.5m.

[0081] The device for enhancing aeration composed of the bubble generating unit 1 and the airlift circulation unit 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com