Thermal-shock-resistant ceramic brick and preparation method thereof

A technology of thermal shock resistance and ceramic quality, applied in the field of architectural ceramics, can solve the problems of low thermal shock resistance, and achieve the effects of improving the sintering degree, solving the reduction of thermal shock resistance, and widening the firing range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

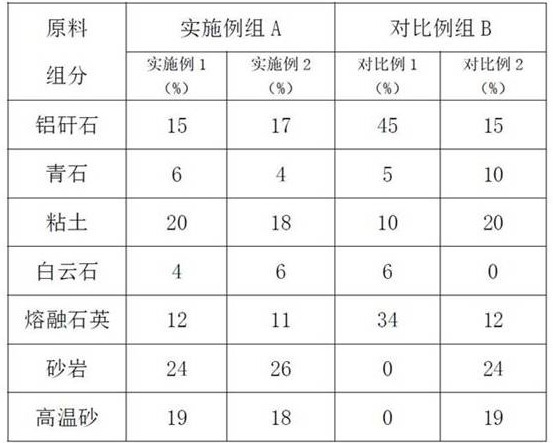

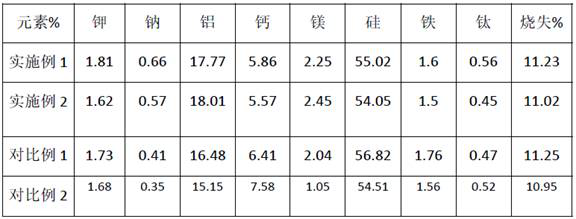

Examples

preparation example Construction

[0047] The present invention also provides a method for preparing thermal shock resistant ceramic bricks. The preparation method of thermal shock resistant ceramic bricks is applied to wide-body kilns for preparing the above-mentioned thermal shock resistant ceramic bricks. bricks, including the following steps:

[0048] Weigh the raw materials according to the ratio, and crush the raw materials so that the particle size of the raw materials is ≦0.5mm;

[0049] The crushed raw materials are ball milled to obtain powder slurry;

[0050] Drying the powder slurry to obtain powder;

[0051] Stale the powder for 48 hours;

[0052] Compressing the powder to obtain a green body and drying the green body;

[0053] Trim the green body, glaze the surface of the green body, and fire it in a wide-body kiln to obtain the thermal shock-resistant ceramic brick.

[0054] In the preparation method of the present invention, the raw materials are first weighed according to the above-mentione...

Embodiment 3

[0079] The components of Example 3 are the same as in Example 1, and the pressing pressure in the preparation step is 21000 MPa, and other steps are the same as in Example 1.

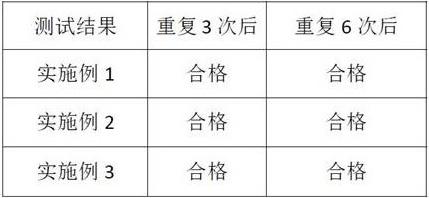

[0080] The thermal shock resistance ceramic bricks prepared in Example Group A and Example 3 above were tested for thermal shock resistance, and Table 3 was obtained.

[0081] The method of thermal shock resistance detection is as follows: raise the temperature of the thermal shock resistance instrument to 180°C±5, place the test sample of 300×600mm in the detection hanging cage of the thermal shock resistance instrument, and after heating for 30 minutes, the hanging cage will automatically put the glaze on Immerse the facing tiles in a water tank with a water temperature of 10-20°C. After soaking for 5 minutes, the hanging cage will automatically rise, and continue to heat at 180°C for 30 minutes; after repeating the above steps 3 times, take out the test sample from the thermal shock resistance instrum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com