Nanoscale polymer microsphere for profile control and flooding and preparation method thereof

A polymer, nano-scale technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of lack of compressibility, poor access, inability to deep profile control, etc., and achieve long water absorption cycle and small particle size. , the effect of enhancing oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

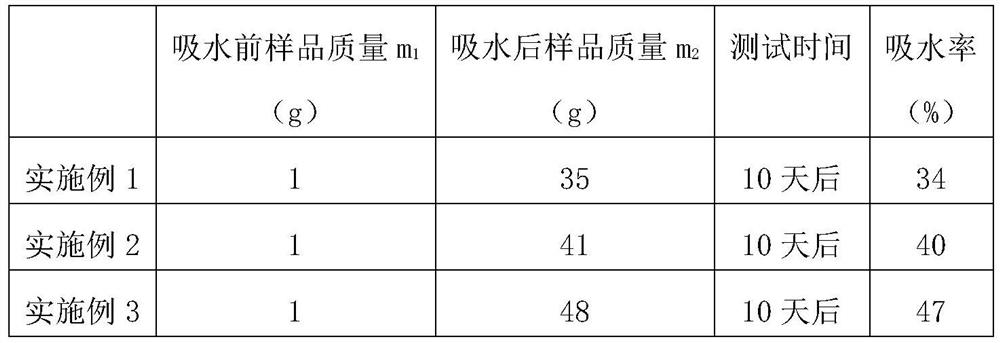

Examples

Embodiment 1

[0023] Weigh 1000g of white oil, 225g of Span 80, and 75g of tween-80 and add them into a 2L four-neck flask, stir evenly to obtain the oil phase;

[0024] Weigh 300g of deionized water and add it to a 1L beaker, then add 380g of acrylamide monomer, 40g of sodium acrylate, and 6g of N,N-methylenebisacrylamide in sequence, stir until the solution is clear, and then add 10g of 25% persulfuric acid The ammonium aqueous solution was stirred evenly, poured into a four-necked flask, stirred evenly, and nitrogen was passed through to exhaust oxygen for 30 minutes, so that the oxygen content in the four-necked flask was below 0.3%;

[0025] Put the four-neck flask into an ice bath, the initial temperature is 20°C, slowly add 10g of 25% sodium sulfite aqueous solution to initiate the reaction, and reach 90°C after 15 minutes, at this time, the reaction temperature will no longer rise, the reaction is ended, and the temperature is lowered to room temperature. Sampling analysis showed th...

Embodiment 2

[0027] Weigh 1000g of white oil, 300g of Span 80 and 100g of tween-80 and add them into a 2L four-neck flask, stir evenly to obtain the oil phase;

[0028] Weigh 410g of deionized water and add it to a 1L beaker, then add 480g of acrylamide monomer, 30g of sodium 2-acrylamide-2-methylpropanesulfonate, and 10g of N,N-methylenebisacrylamide in sequence, and stir until After the solution is clarified, then add 20g of 25% ammonium persulfate aqueous solution, stir evenly, pour it into a four-necked flask, stir evenly, pass nitrogen to exhaust oxygen for 30 minutes, so that the oxygen content in the four-necked flask is below 0.3%;

[0029] Put the four-neck flask in an ice bath, the initial temperature is 20°C, slowly add 15g of 25% sodium sulfite aqueous solution to initiate the reaction, and reach 90°C after 10 minutes, at this time, the reaction temperature will no longer rise, the reaction is ended, and the temperature is lowered to room temperature. Sampling and analysis show...

Embodiment 3

[0031] Weigh 1000g of white oil, 300g of Span 80, and 150g of TX-10 and add them into a 2L four-neck flask, stir evenly to obtain the oil phase;

[0032] Weigh 300g of deionized water and add it to a 1L beaker, then add 430g of acrylamide monomer, 45g of sodium 2-acrylamide-2-methylpropanesulfonate, and 15g of N,N-methylenebisacrylamide in sequence, and stir until After the solution is clarified, then add 20g of 25% ammonium persulfate aqueous solution, stir evenly, pour it into a four-necked flask, stir evenly, pass nitrogen to exhaust oxygen for 30 minutes, so that the oxygen content in the four-necked flask is below 0.3%;

[0033] Put the four-necked flask into an ice bath, the initial temperature is 20°C, slowly add 25g of 25% sodium sulfite aqueous solution to initiate the reaction, and reach 90°C after 10 minutes, at this time, the reaction temperature will no longer rise, the reaction is ended, and the temperature is lowered to room temperature. Sampling and analysis sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com