Anti-bending rubber material for data line and preparation method thereof

A rubber material and anti-bending technology, applied in the field of anti-bending rubber materials and their preparation, can solve the problems of unfavorable tensile strength and bending strength of EPDM rubber, and achieve the increase of the number of binding sites and good tensile strength. Strength and flexural strength, the effect of improving the degree of vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

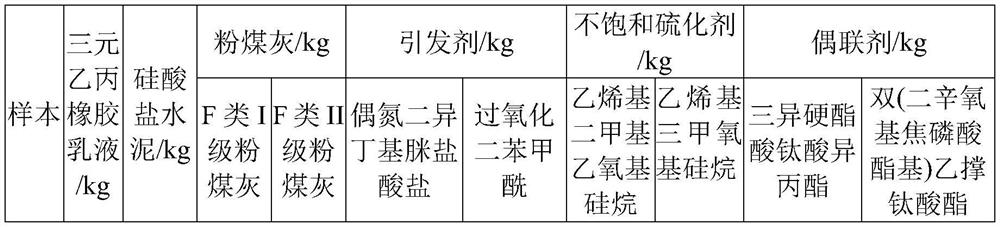

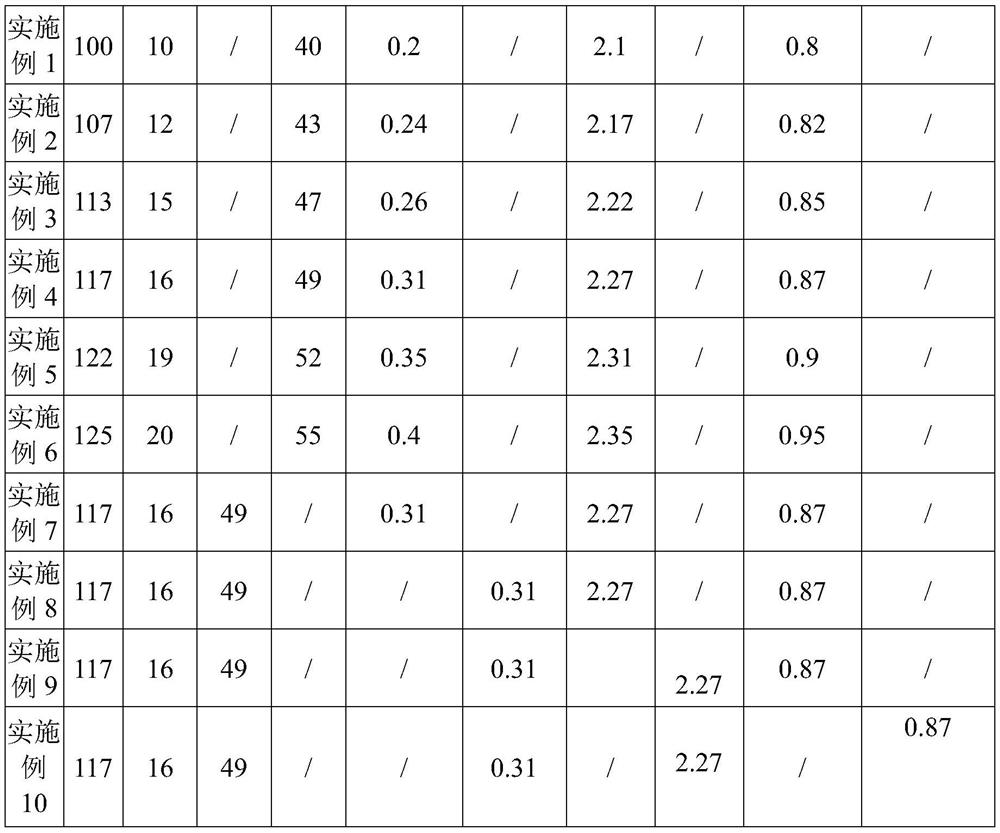

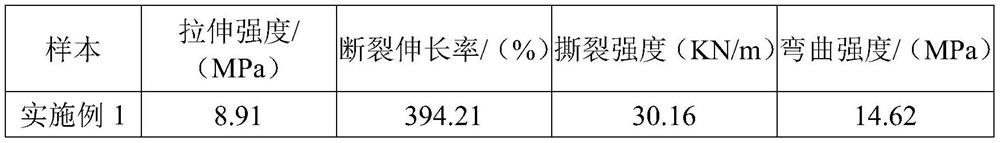

[0041] As shown in Table 1, the main difference of Examples 1-10 is that the ratio of raw materials is different.

Embodiment 1

[0043] In Example 1, the unsaturated vulcanizing agent is selected from vinyl dimethyl ethoxy silane, the initiator is selected from azobisisobutylamidine hydrochloride, the coupling agent is selected from isopropyl triisostearate titanate, powder The coal ash is Class II fly ash of class F.

[0044] The preparation method of the anti-bending rubber material for the data line of Example 1 is as follows:

[0045] (1) Weigh Portland cement and fly ash by weight, and mix and stir at 50°C for 17 minutes to obtain mixture 1, which is set aside;

[0046] (2) Weigh the EPDM emulsion and the coupling agent by weight, add the coupling agent and the mixture 1 into the EPDM emulsion, stir at 55° C. for 30 minutes to obtain the mixture 2, and set aside;

[0047] (3) Weighing the initiator and the unsaturated vulcanizing agent according to parts by weight, adding the initiator and the unsaturated vulcanizing agent into the mixture 2, and fully stirring at 55° C. to obtain the mixture 3; ...

Embodiment 11

[0053] The difference between this example and Example 10 is that the formula also contains 10kg of stabilizer, and the stabilizer is Wenlun glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com