Highly siliceous form of zeolite rho

A zeolite, form technology, applied in the direction of silicate, aluminum silicate, molecular sieve characteristic borosilicate, etc., can solve the problem of no zeolite Rho report, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0082] Another exemplary embodiment is a process comprising synthesizing methylamine from methanol and / or dimethyl ether and ammonia using the composition of the first exemplary embodiment described above, optionally including the one or more.

[0083] Another exemplary embodiment is a method comprising: heating an aqueous reaction mixture to a temperature of at least 75°C in the presence of a structure directing agent, wherein the aqueous reaction mixture has between atomic Si and atomic B The molar ratio between Si and atomic Al is about 4 to about 50, or the molar ratio between atomic Si and atomic Al is about 4 to about 50, and the structure directing agent is selected from compound I, compound II, compound III, or two or Further mixtures of compounds I, II and III. Optionally, this exemplary embodiment may include one or more of the following scenarios: Scenario 8: wherein the aqueous reaction mixture has a molar ratio between atomic Si and structure directing agent of a...

Embodiment 1

[0089] Embodiment 1. Reaction formula 1 illustrates the synthetic method of compound II. 200 mL of anhydrous THF was cannulated into a 500 mL flame-dried round bottom flask with a stir bar. 3.965 g (30.0 mmol) of 2-methylbenzimidazole was added to the flask, and then the flask was purged with nitrogen. The reaction mixture was cooled to -78°C. 12.0 mL (30.0 mmol, 1.0 equivalent) of 2.5M n-butyllithium was added to the reaction mixture, and stirred at -78°C for 5 minutes, then returned to room temperature and stirred at room temperature for 15 minutes. 12.77 g (90.0 mmol, 3.0 equiv) of iodomethane was added, and the reaction was stirred at room temperature for 16 hours. The light brown reaction mixture was poured into 150 mL of deionized water and extracted twice with 75 mL of ethyl acetate and twice with 75 mL of dichloromethane 2x. The combined organic layers were dried over sodium sulfate, filtered via gravity into a pre-weighed round bottom flask, and the solvent was rem...

Embodiment 2

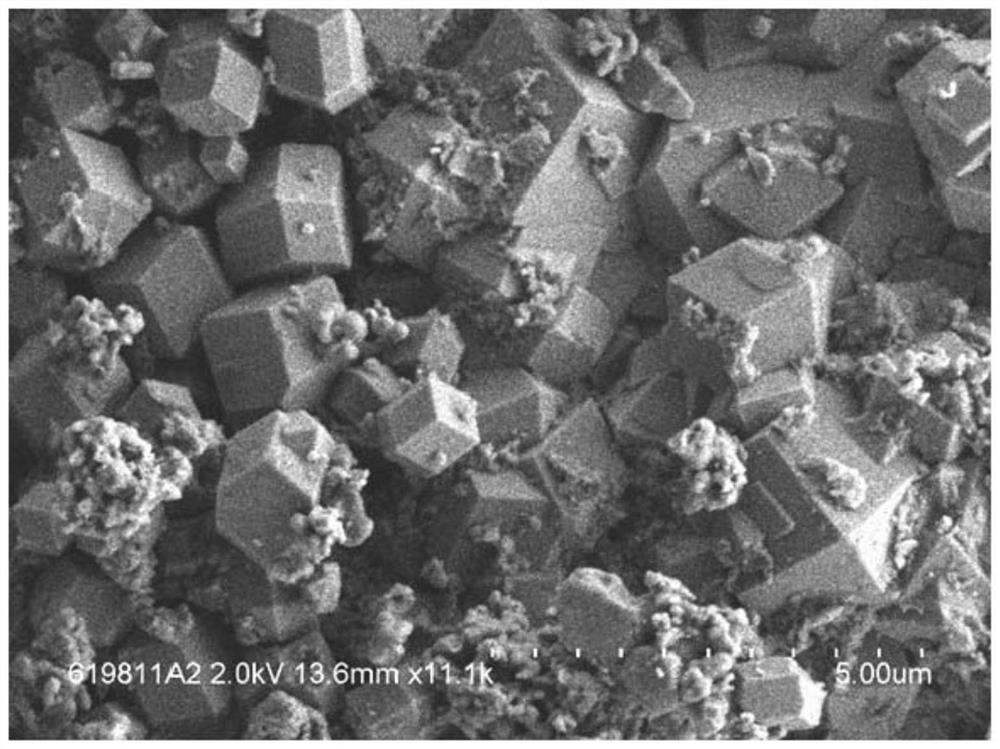

[0094] Example 2 : In a 1.5 mL reactor, the hydroxide solution of boric acid, tetramethyl orthosilicate (TMOS) and compound II was combined with sufficient water such that the molar ratio between atomic Si and atomic B in the reaction mixture is 10, and the molar ratio between atomic Si and SDA is 4. This mixture was then freeze-dried to remove ethanol and most of the water, and then the molar ratio between water and atomic Si was adjusted to 4 by adding deionized water back. The reaction mixture was heated at 150° C. for 10 days, thereby preparing a mixture of borosilicate Rho zeolite and amorphous material. figure 1 is a scanning electron microscope (SEM) photograph of this product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com