Green phenol koji with whitening function and preparation method thereof

A green phenol koji, functional technology, applied in the field of skin care products, can solve the problems of inconvenient large-scale production, long consumption time, complicated extraction process, etc., and achieve the effects of increasing the overall utilization rate, saving the cost of raw materials, and ensuring the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

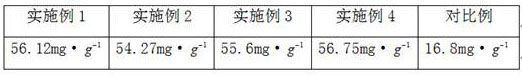

Examples

Embodiment 1

[0022] DIVECTION A germ and preparation method having whitening function, including the following steps:

[0023] S1: Choose green bean leaves, mung bean and mung bean seeds, of which mung bean leaves and mung bean flowers do dry, pulverized, mung bean seeds, dry, grinding treatment, and mixing the quality of the three;

[0024] S2: Mix the lactic acid bacteria powder and bifidobacterial powder or mixed with pure water to obtain a mixed bacterium fermentation liquid, spray the strain mixture to the three mixtures obtained by S1 and placed in the fermentation chamber. 3 days ;

[0025] S3: In S2, it is extracted at 45 ° C for 1 h at 45 ° C in S2 to 1 H. Ethanol with a volume fraction of 55%.

[0026] S4: Take S3 extraction liquid, evaporated to 1 / 3 of the volume of volume under 45 ° C, and the concentrate is lyophilized.

[0027] The green bean leaves in S1, the mung bean pelets are pulverized to 1 mm, and the green bean seed is ground to 30 mesh. The lactacteria powder and bifidob...

Embodiment 2

[0032] The technical solution of the present invention has a grease and preparation method of whitening function, including the following steps:

[0033] S1: Choose green bean leaves, mung bean and mung bean seeds, of which mung bean leaves and mung bean flowers do dry, pulverized, mung bean seeds, dry, grinding treatment, and mixing the quality of the three;

[0034] S2: Mix the lactic acid bacteria powder and bifidobacterial powder and mixed into pure water to obtain a mixed bacterium fermentation liquid, spray the strain mixture to the three mixtures obtained by S1 and placed in the fermentation room. 5 days ;

[0035] S3: The liquid ratio of 1: 12 g / ml and the volume fraction of 60% is mixed at 50 ° C at 50 ° C for 2 h at 50 ° C in S2.

[0036] S4: The extraction liquid of S3 was removed at 55 ° C, and the vapor was evaporated to 1 / 5 of the volume of volume, and the concentrate was lyophilized.

[0037] S1 in green bean leaves, mung beanioma is pulverized to 2 mm, mung bean ...

Embodiment 3

[0043] The technical solution of the present invention has a grease and preparation method of whitening function, including the following steps:

[0044] S1: Choose green bean leaves, mung bean and mung bean seeds, of which mung bean leaves and mung bean flowers do dry, pulverized, mung bean seeds, dry, grinding treatment, and mixing the quality of the three;

[0045] S2: Mix the lactic acid bacteria powder and bifidobacterial powder or mixed with pure water to obtain a mixed bacterium fermentation liquid, spray the strain mixture to the three mixtures obtained by S1 and placed in the fermentation chamber. 3 days ;

[0046] S3: The liquid ratio of 1: 15 g / ml and the volume fraction of 55% is mixed at 45 ° C for 1 h at 45 ° C in S2.

[0047] S4: Take S3 extraction liquid, evaporated to 1 / 3 of the volume of volume under 45 ° C, and the concentrate is lyophilized.

[0048] The green bean leaves in S1, the mung bean pelets are pulverized to 1 mm, and the green bean seed is ground to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com