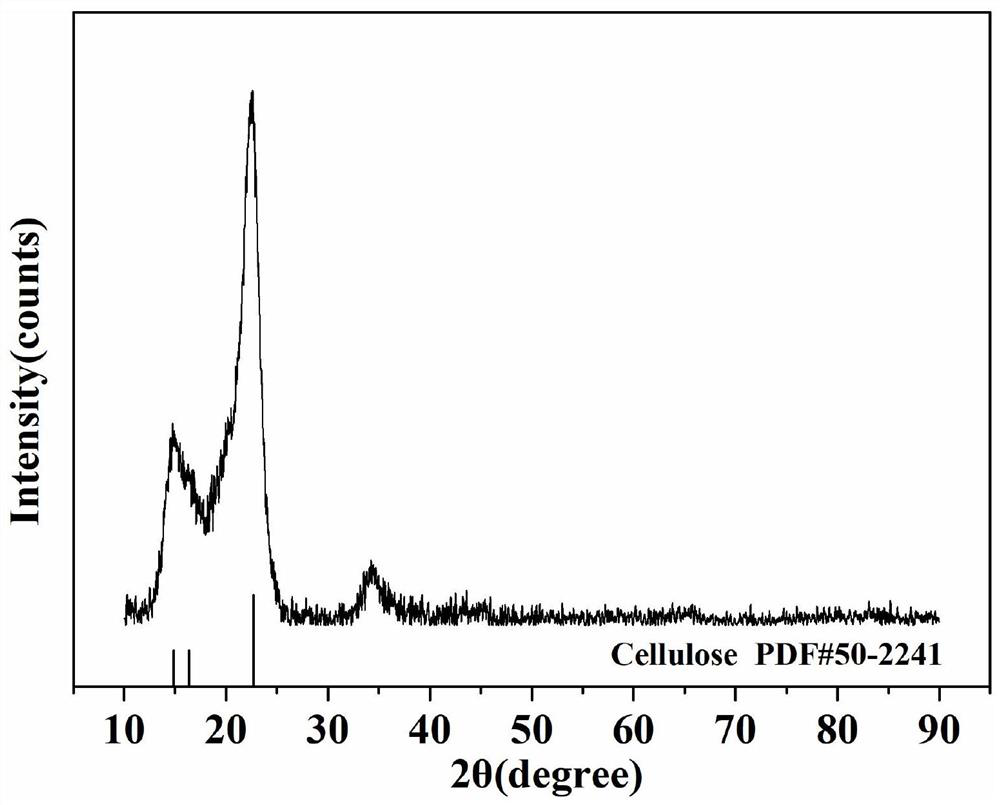

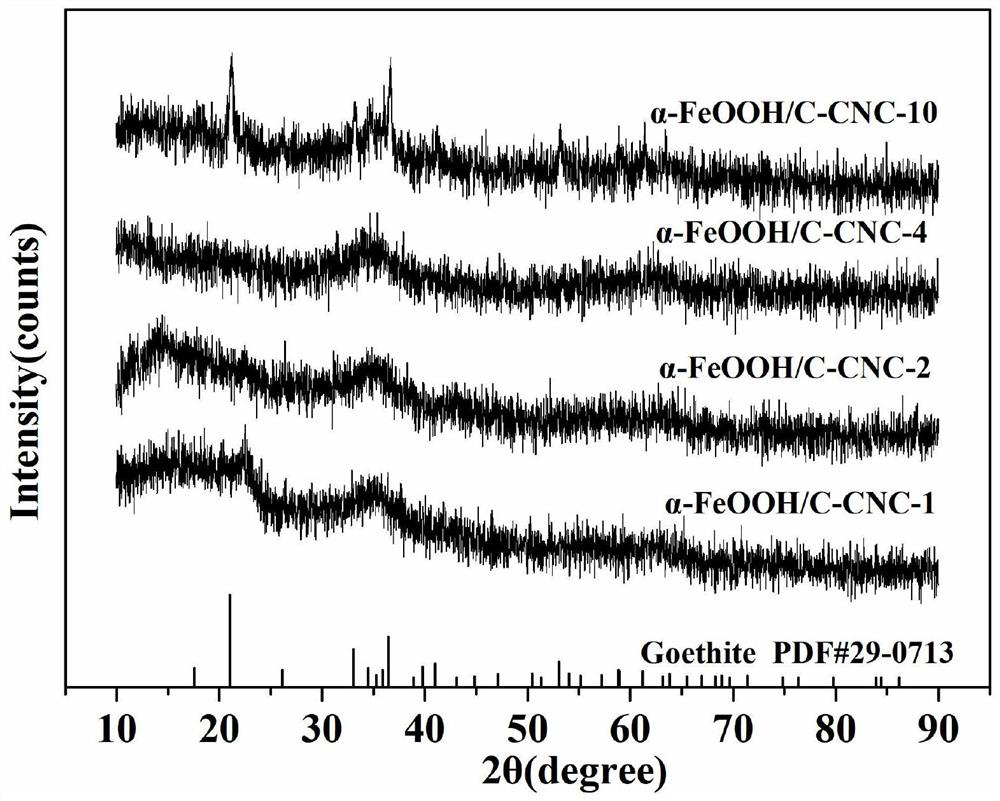

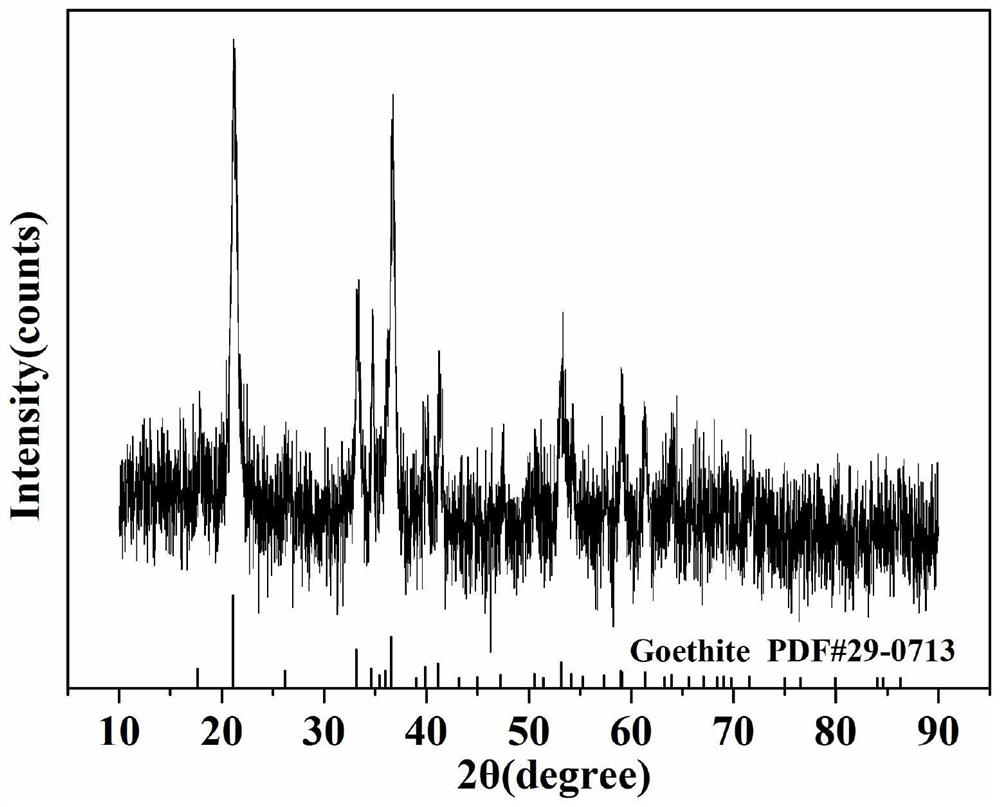

Preparation method of goethite/carboxylated cellulose nanocrystalline composite material for removing heavy metal ions

A technology of carboxylated cellulose and heavy metal ions, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc. Stable and rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a goethite / carboxylated cellulose nanocrystalline composite material and a preparation method thereof, comprising the following steps:

[0039] (1) At room temperature, 32.5 g of 3.2 wt % carboxylated cellulose nanocrystals were dispersed in 67.5 g of deionized water, and magnetically stirred for 20 min to form a 1 wt % carboxylated cellulose nano crystal dispersion.

[0040] (2) add 1~10g Fe(NO in the dispersion liquid that step (1) obtains 3 ) 3 9H 2 O, magnetically stirred at room temperature for 8 h to obtain Fe 3+ / carboxylated cellulose nanocrystal complex mixture.

[0041] (3) Add 5M NaOH solution to the mixed solution obtained in step (2) while stirring to adjust the pH of the mixed solution to pH>13, and continue stirring for 30 s.

[0042](4) Transfer the mixed solution obtained in the step (3) to a hydrothermal reaction kettle and seal it, place it in an oven for hydrothermal reaction at 70°C for 12 hours, and wash the product re...

Embodiment 2

[0050] (1) Disperse 32.5g of 3.2wt% carboxylated cellulose nanocrystals in 67.5g of deionized water at room temperature, and magnetically stir for 20min to form a 1wt% carboxylated cellulose nanocrystal dispersion.

[0051] (2) in the dispersion liquid that described step (1) obtains, add 1g Fe (NO 3 ) 3 9H 2 O, magnetically stirred at room temperature for 8 h to obtain Fe 3+ / carboxylated cellulose nanocrystal complex mixture.

[0052] (3) Add 5M NaOH solution to the mixed solution obtained in step (2) while stirring to adjust the pH of the mixed solution to pH>13, and continue stirring for 30 s.

[0053] (4) Transfer the mixed solution obtained in the step (3) to a hydrothermal reaction kettle and seal it, place it in an oven for hydrothermal reaction at 70°C for 12 hours, and wash the product repeatedly with deionized water after the reaction is over. properties, and then washed 2 to 3 times with absolute ethanol, placed in a vacuum drying oven at 50 ° C and dried for ...

Embodiment 3

[0060] (1) Disperse 32.5g of 3.2wt% carboxylated cellulose nanocrystals in 67.5g of deionized water at room temperature, and magnetically stir for 20min to form a 1wt% carboxylated cellulose nanocrystal dispersion.

[0061] (2) in the dispersion liquid that described step (1) obtains, add 1g Fe (NO 3 ) 3 9H 2 O, magnetically stirred at room temperature for 8 h to obtain Fe 3+ / carboxylated cellulose nanocrystal complex mixture.

[0062] (3) Add 5M NaOH solution to the mixed solution obtained in step (2) while stirring to adjust the pH of the mixed solution to pH>13, and continue stirring for 30 s.

[0063] (4) Transfer the mixed solution obtained in the step (3) to a hydrothermal reaction kettle to seal it, place it in an oven for hydrothermal reaction at 70°C for 12 hours, and wash the product repeatedly with deionized water after the reaction is over. properties, and then washed with absolute ethanol for 2 to 3 times, placed in a vacuum drying oven at 50 ° C and dried f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com