Alternating-current and direct-current dual-purpose high-blowing-force cellulose welding rod

It is a dual-purpose AC and DC technology with high blowing force. It is applied in the direction of welding medium, welding equipment, welding equipment, etc. It can solve the problems that the strength is not enough to meet the strength, and achieve the effect of beautiful shape, improved work efficiency, and reduced manual maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In addition to the definition, the technical terms used in the following examples have the same meaning as those in those skilled in the art of the present invention. The test reagents used in the following examples are all conventional biochemical agents, and the experimental methods, such as non-special descriptions, are conventional methods.

[0023] The present invention will be described in connection with the examples.

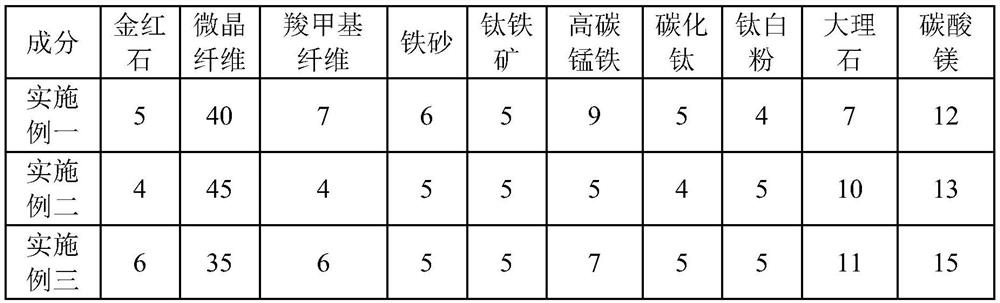

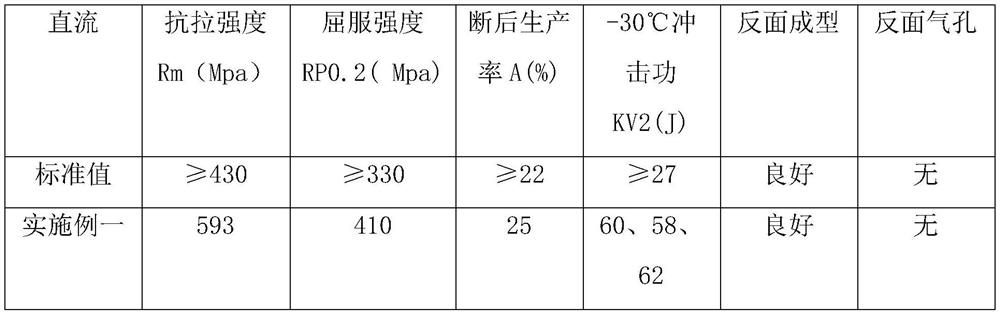

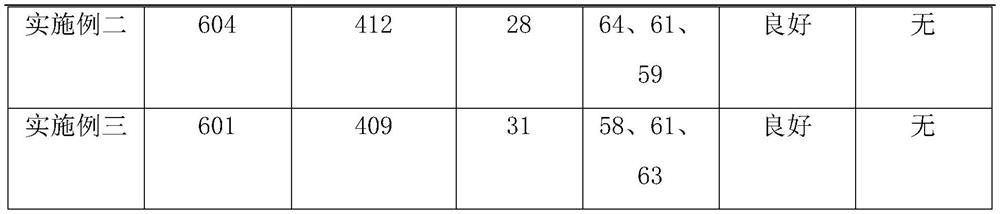

[0024] The hydrozo powder powder raw material of the present invention has been strictly dispristed, and each of the raw materials is a strict chemical component range, and controlling part of the raw material particle size (particles control through the screen, excluding large particles and uneven particles) To ensure the strength of the particles of the flux. In the production process, the full online monitoring is implemented, and the powder powder is prepared in a certain proportion, and the water glass is added to the excipient mixed powder, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com