Solution and method for extracting radionuclides from high-level radioactive vitreous bodies

A radionuclide and vitreous technology, applied in the field of radionuclide extraction solutions, can solve the problems of harsh conditions, easy formation of strong corrosive volatile gases, and high concentration of lye, achieve mild composition, promote final processing, and extraction capabilities strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

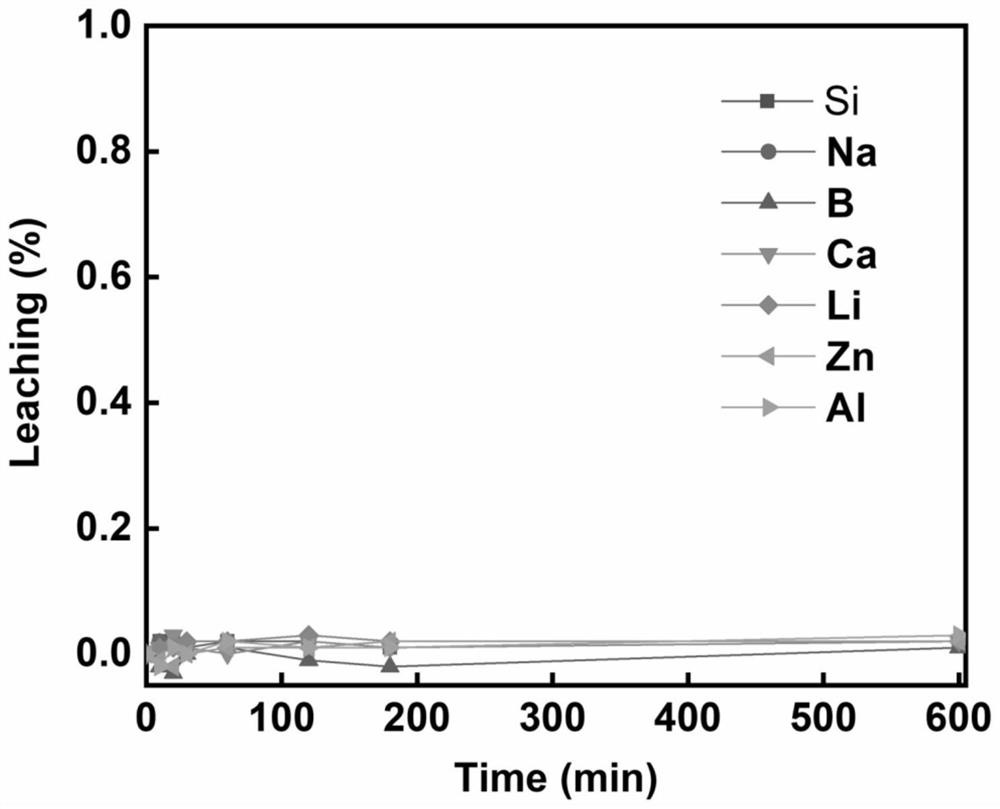

[0030] 1) Preparation of simulated high-radiation glass: using main glass forming reagents (including: SiO 2 , B 2 o 3 、Na 2 O, Al 2 o 3 , ZnO, CaO and Li 2 O) and various metal oxides (including: La 2 o 3 、Nd 2 o 3 , ZrO 2 、Cs 2 O, PdO, Rh 2 o 3 , RuO 2 and SeO 2 ). La, Pd, Ru, Rh, and Cs are respectively selected as representative nuclides of lanthanides, PGM, and alkaline earth elements. Please refer to Table 1 for detailed composition and dosage of each component. These reagents (purchased from Sinopharm Chemical Reagent Co., Ltd.) are non-radioactive and mixed uniformly. With the content of the ingredients listed in Table 1, mix the glass forming reagent and metal oxide powder in a 100mL alumina crucible, heat at 1450°C for 2h, then cool the glass melt to room temperature, and crush it to 100-300μm to obtain glass Solidified powder. The following examples and comparative examples of the present invention are implemented using the glass solidified body po...

Embodiment 1

[0042] The present embodiment extracts the method for radionuclide from the high-level glass solidified body, and its process is as follows:

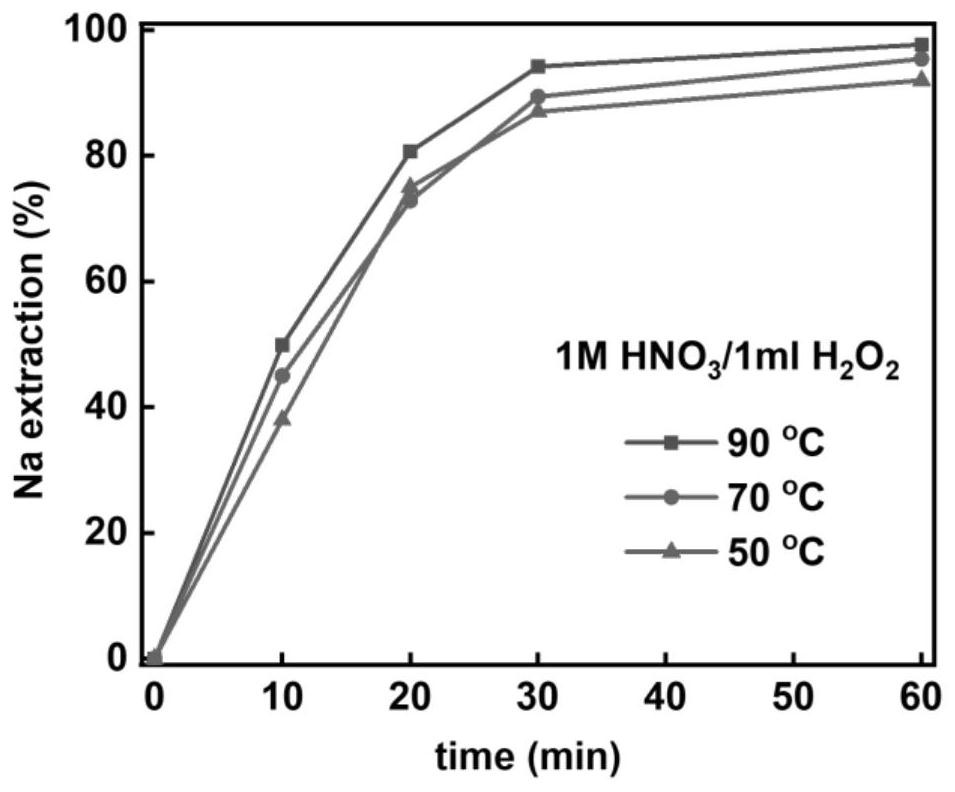

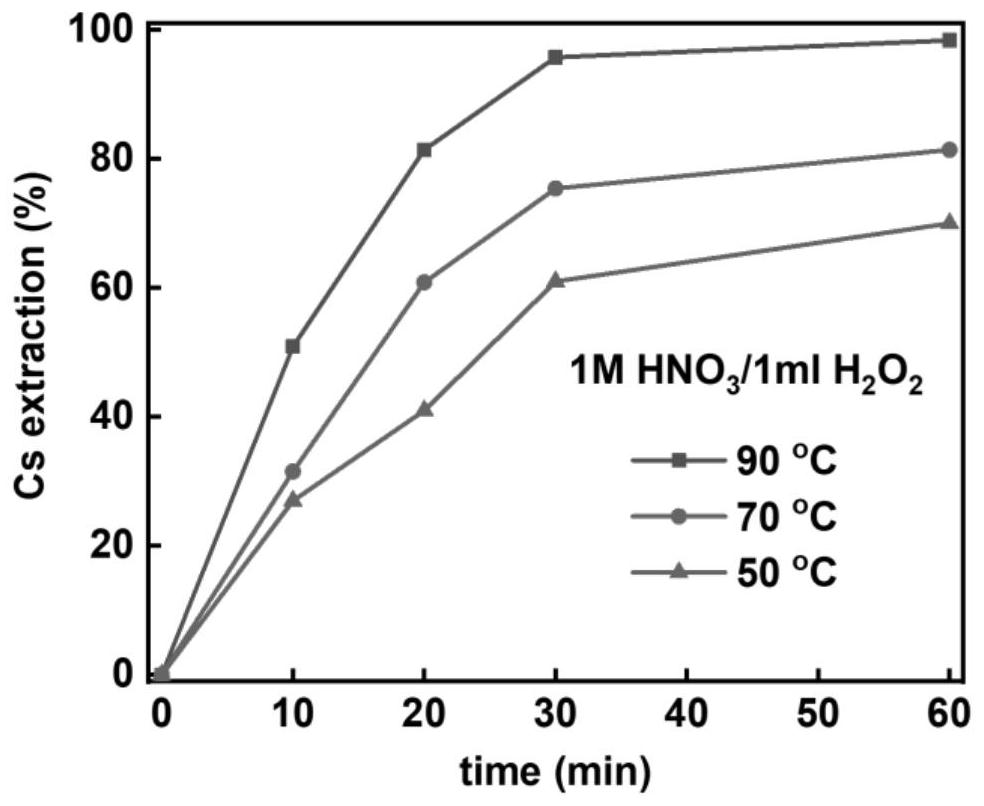

[0043] The self-made vitrified body powder was added to the mixed solution of hydrogen peroxide / nitric acid with different content ratios, wherein the amount of hydrogen peroxide added was 1 mL, and the concentration of nitric acid was 1 mol / L. The liquid / solid ratio was 20 / 1 mL / g. Put the above-prepared solid-liquid mixture into an oven, heat it up to 90°C, keep it warm for 1 hour, and then cool it down to room temperature. After the impregnation experiment, the supernatant was collected by centrifugation and analyzed for element concentration by ICP-MS. Referring to Figure 2(a) and Figure 2(b), the leaching rates of Na and Cs are 97.69% and 98.37%, respectively.

Embodiment 2

[0045] The present embodiment extracts the method for radionuclide from the high-level glass solidified body, and its process is as follows:

[0046] The self-made vitrified body powder was added to the mixed solution of hydrogen peroxide / nitric acid with different content ratios, wherein the amount of hydrogen peroxide added was 1 mL, and the concentration of nitric acid was 1 mol / L. The liquid / solid ratio was 20 / 1 mL / g. Put the above-prepared solid-liquid mixture into an oven, heat up to 50°C, keep it warm for 1 hour, and then cool to room temperature. After the impregnation experiment, the supernatant was collected by centrifugation and analyzed for element concentration by ICP-MS. Referring to Figure 2(a) and Figure 2(b), the leaching rates of Na and Cs are 92% and 70%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com