Silicon carbide epitaxial layer, etching method thereof and silicon carbide device

A silicon carbide and epitaxial layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of easy formation of micro-channels at sidewalls and corners, reducing the reliability of silicon carbide device etching, etc. Etching, preventing the formation of etched patterns, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

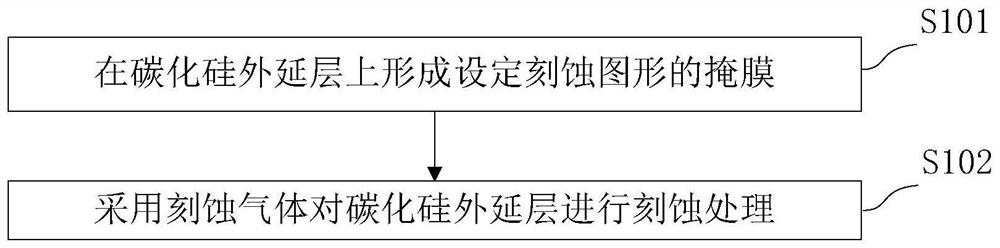

[0032] Such as figure 1 As shown, the etching method of the silicon carbide epitaxial layer in this embodiment includes:

[0033] S101, forming a mask for setting an etching pattern on the silicon carbide epitaxial layer;

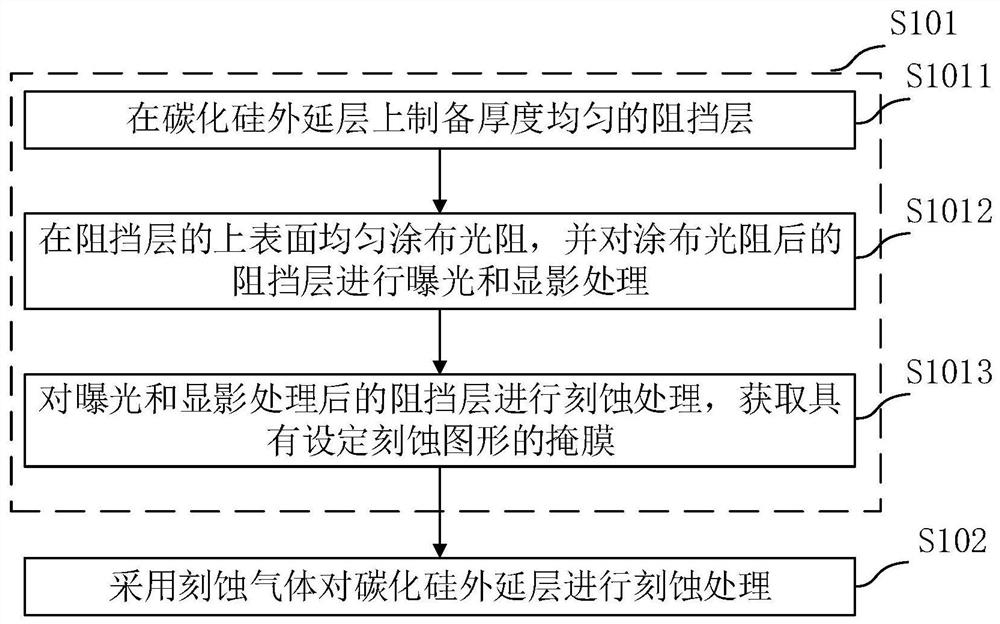

[0034] Specifically, such as figure 2 As shown, step S101 includes:

[0035] S1011, preparing a barrier layer with a uniform thickness on the silicon carbide epitaxial layer;

[0036] Specifically, a CVD (Chemical Vapor Deposition) method is used to prepare a barrier layer with uniform thickness on the silicon carbide epitaxial layer.

[0037] S1012, uniformly coating photoresist on the upper surface of the barrier layer, and performing exposure and development treatment on the barrier layer coated with photoresist; wherein, coating the photoresist by using a coating device.

[0038] S1013. Etching the exposed and developed barrier layer to obtain a mask with a set etching pattern;

[0039] Wherein, the barrier layer includes but not limited to silico...

Embodiment 2

[0054] The silicon carbide epitaxial layer of this embodiment is obtained by using the etching method of the silicon carbide epitaxial layer in Embodiment 1.

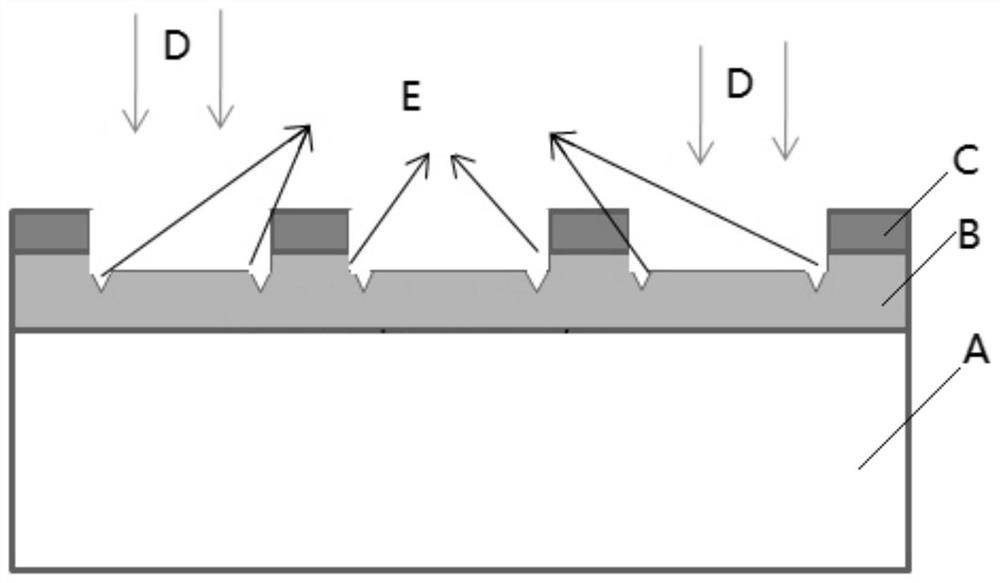

[0055] The silicon carbide epitaxial layer in this embodiment is obtained by etching with chlorine gas, argon gas and hydrogen bromide etching gas, which effectively prevents the formation of microchannels at the etched pattern.

Embodiment 3

[0057] The silicon carbide device of this embodiment includes the silicon carbide epitaxial layer in Embodiment 2.

[0058] In this embodiment, the silicon carbide epitaxial layer obtained by etching with chlorine gas, argon gas and hydrogen bromide etching gas is used to ensure the reliability of the silicon carbide device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com