Nutritional and healthy germinated highland barley biscuits based on 3D printing technology and making method thereof

A production method and 3D printing technology, applied in the field of food 3D printing, can solve the problems of germinated barley flour biscuit research and lack of patents, etc., achieve high market application value, regulate hormone metabolism, and reduce PGI value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

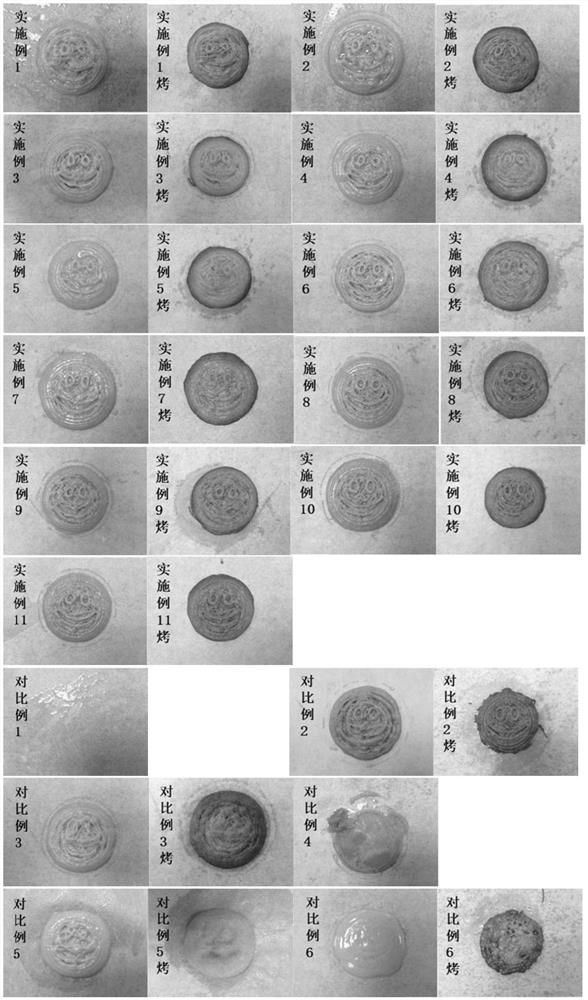

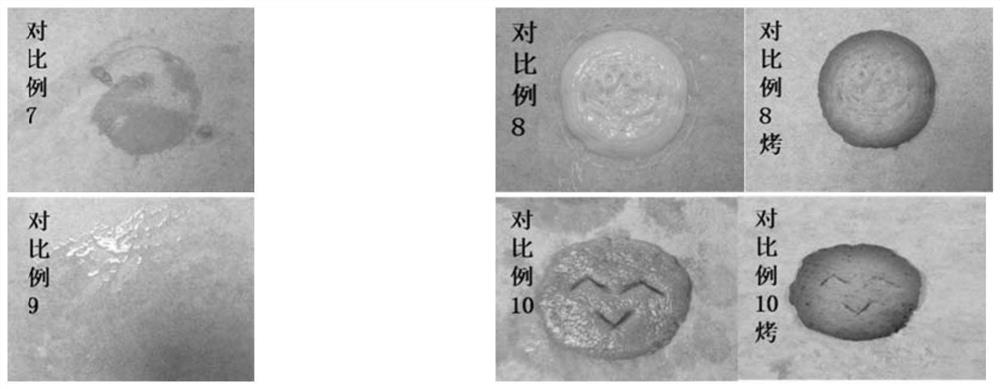

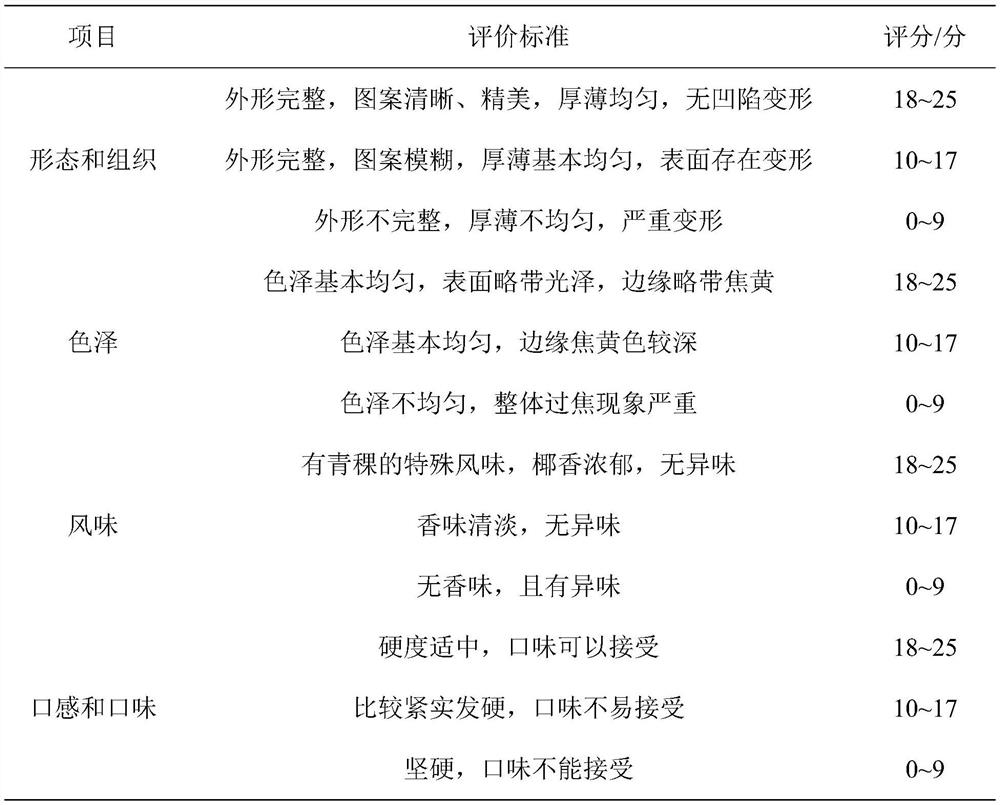

Examples

Embodiment 1

[0031] The raw and auxiliary materials of the germinated highland barley biscuit include the following components in parts by weight: 50 parts of germinated highland barley powder, 50 parts of wheat flour, 10 parts of inulin, 10 parts of soybean powder, 20 parts of erythritol, 0.01 part of mogroside, coconut 62 parts of oil, 60 parts of water.

[0032] The main preparation process of 3D printed germinated barley biscuits is as follows:

[0033] (1) Preparation of germinated highland barley flour: Soak the highland barley grains in clear water at room temperature for 6 hours, then germinate them for 40 hours at a temperature of 27° C. and a relative humidity of 99%, dry the germinated seeds at 45° C. for 10 hours, and pulverize Pass through a 80-mesh sieve.

[0034] (2) 3D printing: select a 0.8cm printing nozzle, put the premixed raw and auxiliary materials into the material bucket of the hot extrusion 3D printer to prepare for printing, and set the printing conditions for th...

Embodiment 2

[0037] The raw and auxiliary materials of the germinated highland barley biscuit include the following components in parts by weight: 50 parts of germinated highland barley powder, 50 parts of wheat flour, 10 parts of inulin, 10 parts of soybean powder, 20 parts of erythritol, 0.01 part of mogroside, coconut 62 parts of oil, 60 parts of water.

[0038] The main preparation process of 3D printed germinated barley biscuits is as follows:

[0039] (1) Preparation of germinated highland barley flour: Soak the highland barley grains in clear water at room temperature for 6 hours, then germinate them for 40 hours at a temperature of 27° C. and a relative humidity of 99%, dry the germinated seeds at 45° C. for 10 hours, and pulverize Pass through a 80-mesh sieve.

[0040] (2) 3D printing molding: select a 1cm printing nozzle, put the premixed raw and auxiliary materials into the material barrel of the hot extrusion 3D printer to prepare for printing, and set the printing conditions ...

Embodiment 3

[0043] The raw and auxiliary materials of the germinated highland barley biscuit include the following components in parts by weight: 50 parts of germinated highland barley powder, 50 parts of wheat flour, 10 parts of inulin, 10 parts of soybean powder, 20 parts of erythritol, 0.01 part of mogroside, coconut 32 parts of oil, 88 parts of water.

[0044] The main preparation process of 3D printed germinated barley biscuits is as follows:

[0045] (1) Preparation of germinated highland barley powder: Soak the highland barley grains in clear water at room temperature for 8 hours, then germinate them for 36 hours at a temperature of 27° C. and a relative humidity of 99%, dry the germinated seeds at 50° C. for 8 hours, and pulverize Pass through a 80-mesh sieve.

[0046] (2) 3D printing: select a 1cm print nozzle, put the premixed raw and auxiliary materials into the material barrel of the hot extrusion 3D printer to prepare for printing, and set the printing conditions of the smil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com