A medium dielectric constant high q microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and dielectric constant technology, applied in the field of electronic functional materials and devices, can solve problems such as inability to meet, and achieve the effects of increasing the Q×f value, reducing dielectric loss, and reducing the concentration of defects such as oxygen vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) According to the mass fraction of 2.1% BaO, 5.7% SrO, 63.5% La 2 o 3 , 27.5%TiO 2 , 1.2% Al 2 o 3 Proportioning, weigh barium carbonate, strontium carbonate, lanthanum oxide, titanium dioxide (rutile phase), aluminum oxide, add the alcohol of suitable content, carry out planetary ball mill 8 hours;

[0028] 2) Dry the slurry, pre-fire it at 1450°C for 4 hours after sieving;

[0029] 3) Ball mill the obtained powder for another 4 hours, dry and sieve, add an appropriate amount of polyvinyl alcohol aqueous solution (PVA), grind and granulate, and shape by dry pressing.

[0030] 4) Finally, debinding the green body at 600°C for 4 hours, and then sintering at 1600°C for 4 hours to obtain the ceramic material with the desired chemical composition ratio.

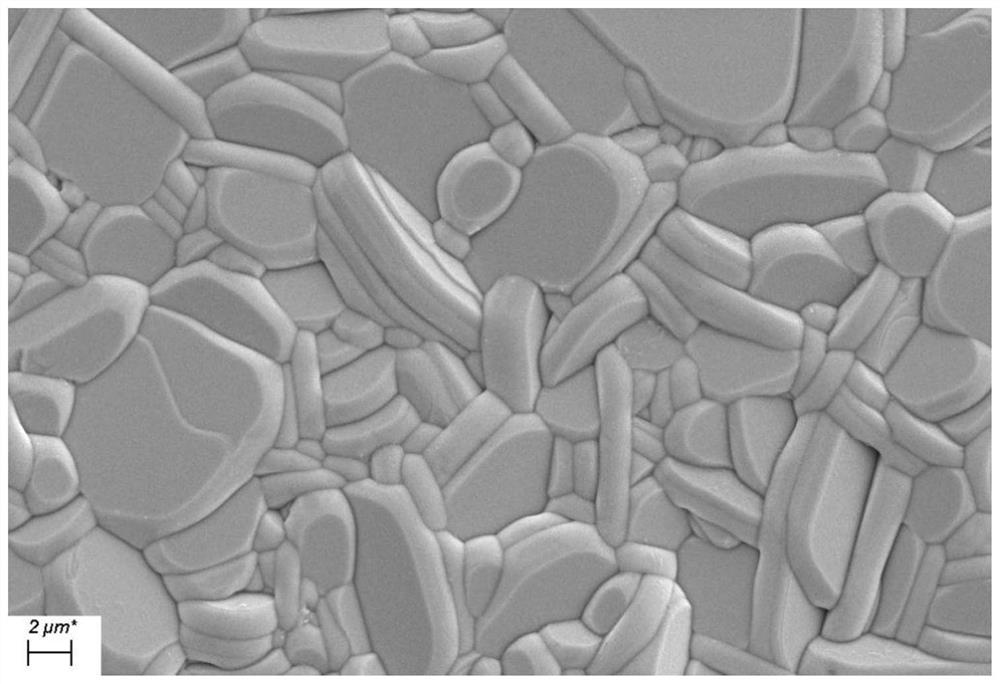

[0031] SEM surface morphology of ceramics as figure 1 As shown, it can be seen that the density of ceramics is higher, the pores are less, and its bulk density is 6.1g / cm 3 , with an average grain size of 3 μm. T...

Embodiment 2

[0033] 1) According to the mass fraction of 2.9% BaO, 7.7% SrO, 60.8% La 2 o 3 , 22.3%TiO 2 , 6.3% Al 2 o 3 Proportioning, weigh barium carbonate, strontium carbonate, lanthanum oxide, titanium dioxide (rutile phase), aluminum oxide, add the alcohol of suitable content, carry out planetary ball mill 8 hours;

[0034] 2) Dry the slurry, pre-fire it at 1450°C for 4 hours after sieving;

[0035] 3) Ball mill the obtained powder for another 4 hours, dry and sieve, add an appropriate amount of polyvinyl alcohol aqueous solution (PVA), grind and granulate, and shape by dry pressing.

[0036] 4) Finally, debinding the green body at 600°C for 4 hours, and then sintering at 1650°C for 4 hours to obtain the ceramic material with the desired chemical composition ratio.

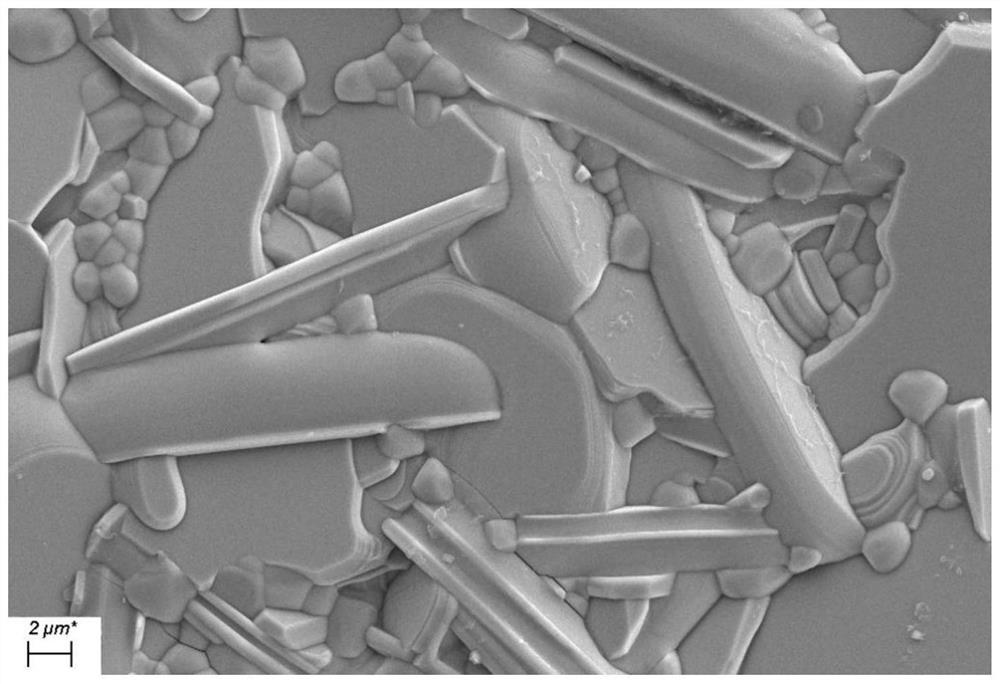

[0037] SEM surface morphology of ceramics as image 3 As shown, it can be seen that the density of ceramics is higher, the pores are less, and its bulk density is 6.1g / cm 3 . The dielectric constant measured by a...

Embodiment 3

[0039] 1) According to the mass fraction of 2.8% BaO, 7.6% SrO, 59.6% La 2 o 3 , 30.0%TiO 2 Proportioning, weigh barium carbonate, strontium carbonate, lanthanum oxide, titanium dioxide (rutile phase), add the alcohol of suitable content, carry out planetary ball mill 8 hours;

[0040] 2) Dry the slurry, pre-fire it at 1450°C for 4 hours after sieving;

[0041] 3) Ball mill the obtained powder for another 4 hours, dry and sieve, add an appropriate amount of polyvinyl alcohol aqueous solution (PVA), grind and granulate, and shape by dry pressing.

[0042] 4) Finally, debinding the green body at 600°C for 4 hours, and then sintering at 1600°C for 4 hours to obtain the ceramic material with the desired chemical composition ratio.

[0043] The bulk density of ceramics is 6.0g / cm 3 . The dielectric constant measured by a network analyzer is 48.1, the Q×f value is 51600GHz, and the temperature coefficient of the resonant frequency is -0.8ppm / ℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com