Heavy metal sulfydryl adsorption material and preparation method thereof

A technology for adsorption materials and heavy metals, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of low modification efficiency of mercapto resin, achieve good treatment effect, high removal rate, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

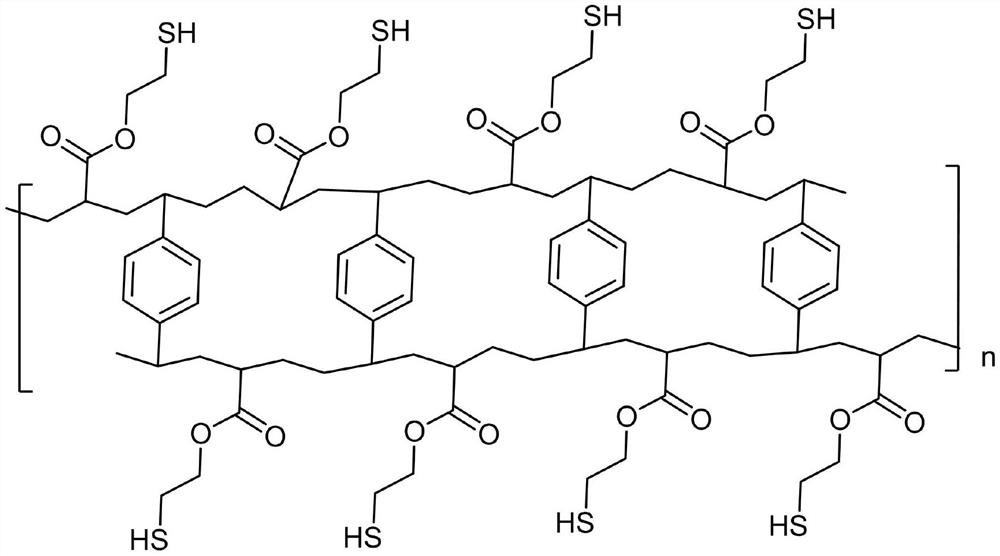

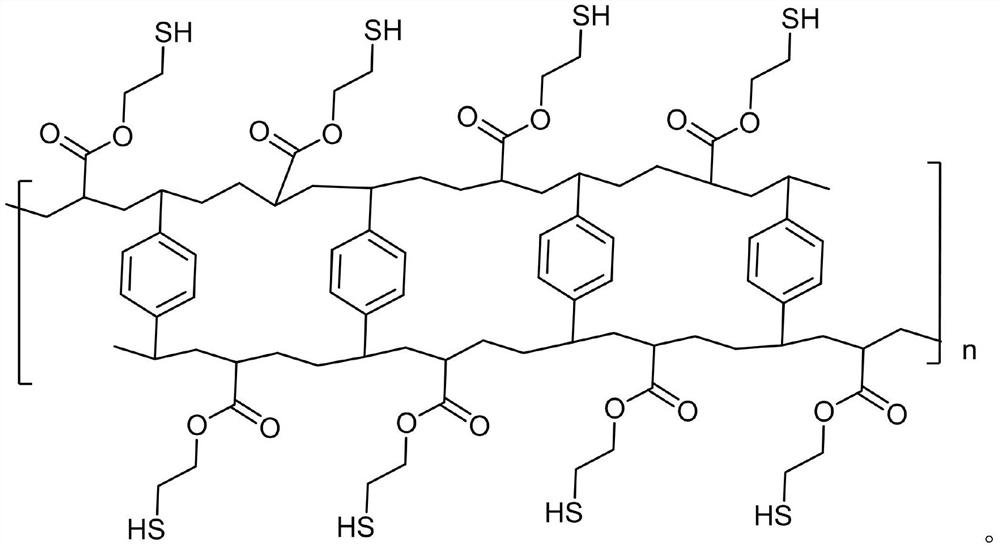

Image

Examples

Embodiment 1

[0022] Step 1. Add 72g of acrylic acid and 7.82g of mercaptoethanol to the reactor, add 1.9g of p-toluenesulfonic acid and 400ml of THF under stirring conditions, heat and reflux at 70°C for 4h to obtain mercaptoethyl acrylate, and distill under reduced pressure, Washed three times with water and dried to obtain mercaptoethyl acrylate.

[0023] Step 2. mix the obtained mercaptoethyl acrylate with 13g divinylbenzene press, add 1g benzoyl peroxide, obtain oily phase; then, add 500mL deionized water containing 0.05%~0.1% polyvinyl alcohol, in Under stirring conditions, the oil phase is dispersed into oil beads in the water phase, and the diameter of the oil beads is controlled. At the same time, it is heated to 60°C and reacted for 6 hours to carry out a polymerization reaction. After the reaction, cool and filter to obtain a mercapto alcohol-modified acrylic acid polymer. .

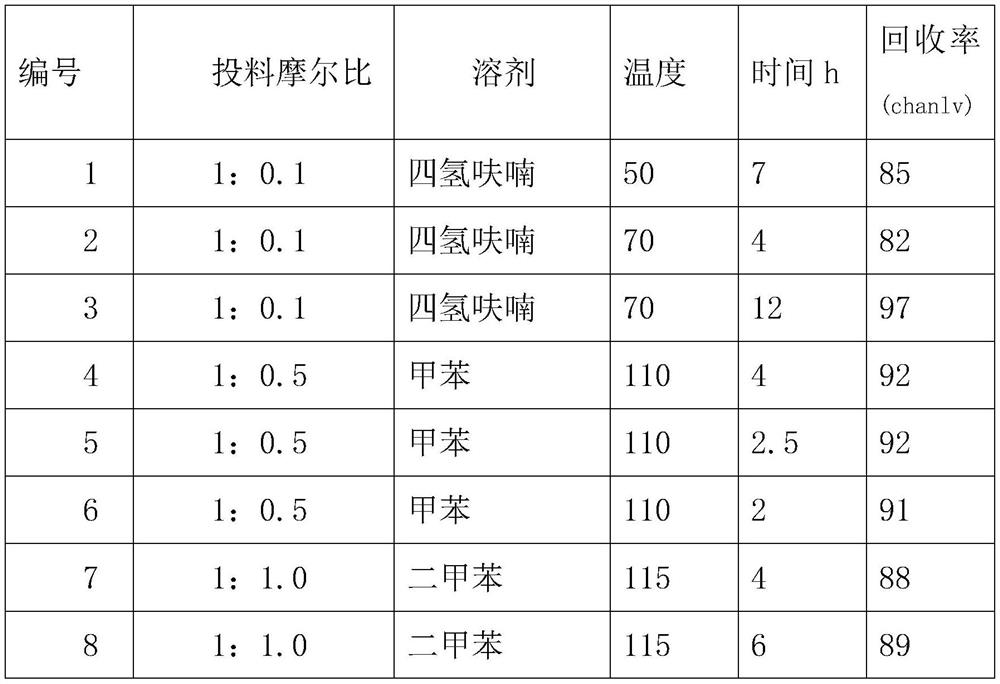

[0024] Synthesis shown in table 1 is carried out with reference to the method described in example 1 st...

Embodiment 2

[0029] Add 72g of acrylic acid and 93.76g of mercaptoethanol into the reactor, add 7g of p-toluenesulfonic acid and 600ml of THF under stirring conditions, heat and reflux at 70°C for 5h to obtain mercaptoethyl acrylate, distill under reduced pressure, and wash with water three times. Dry to obtain product mercapto acrylate. Mix the obtained mercaptoethyl acrylate with 13 g of divinylbenzene, add 1 g of benzoyl peroxide to obtain an oil phase; then, add 500 mL of deionized water containing 0.05% to 0.1% of polyvinyl alcohol, and stir The oil phase is dispersed into oil droplets in the water phase, and the diameter of the oil droplets is controlled. At the same time, it is heated to 60° C. for 6 hours to carry out a polymerization reaction. After the reaction, it is cooled and filtered to obtain a mercapto alcohol-modified acrylic acid polymer.

Embodiment 3

[0031] Add 72g of acrylic acid and 10.6g of 2-mercapto-3-butanol into the reactor, add 2g of p-toluenesulfonic acid and 400ml of THF under stirring conditions, heat and reflux at 70°C for 2h to obtain mercaptobutyl acrylate, and distill under reduced pressure , washed with water three times, and dried to obtain the product mercaptobutyl acrylate. Mix the obtained mercaptobutyl acrylate with 15g of divinylbenzene, add 1g of benzoyl peroxide to obtain an oil phase; then, add 500mL of deionized water containing 0.05% to 0.1% of polyvinyl alcohol, and stir The oil phase is dispersed into oil droplets in the water phase, and the diameter of the oil droplets is controlled. At the same time, it is heated to 60° C. for 6 hours to carry out a polymerization reaction. After the reaction, it is cooled and filtered to obtain a mercapto alcohol-modified acrylic acid polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com