Wear-resistant low-noise soft brake pad and preparation method thereof

A brake pad and soft technology, applied in the field of brake materials, can solve the problems of a lot of dust and high noise of the brake pad, and achieve the effects of stable friction coefficient, small thermal expansion rate and improved braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The first aspect of the present invention provides a wear-resistant and low-noise soft brake pad, comprising the following raw materials in parts by weight: 48-54 parts of anti-friction rubber particles, 7.5-13 parts of barite powder, 2-2 parts of artificial graphite 7 parts, 1-6 parts of friction powder, 4-9 parts of coke, 1-6 parts of yellow vermiculite, 0.4-5 parts of high-temperature calcined alumina, 7-16 parts of flake graphite containing 94% fixed carbon, 1-5 parts of aramid fiber 2-8 parts of zircon powder, 1-5 parts of calcium sulfate whiskers, 1-6 parts of heavy magnesium containing 90% magnesium, 1-3 parts of talcum powder;

[0034] The friction-reducing rubber particles include the following raw materials in parts by weight: 8 parts of rubber, 7 parts of reinforcing fiber, and 12 parts of thermosetting resin;

[0035] The rubber is one or more of styrene-butadiene rubber, nitrile rubber, chlorinated polyisobutylene rubber and silicone rubber;

[0036] The r...

Embodiment 2

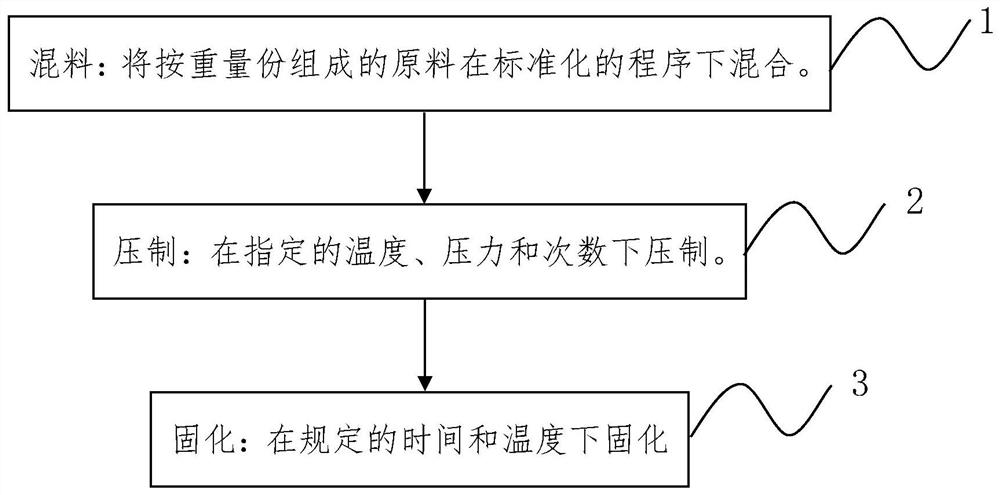

[0045] figure 1 It is the preparation flowchart of the present invention.

[0046] A second aspect of the present invention provides a method for preparing a wear-resistant and low-noise soft brake pad, comprising the following steps:

[0047](1) Mixing: Use a plow-type mixer with a reamer or a vertical high-speed mixer for mixing, add all raw materials except aramid fiber and flake graphite to the mixer and start the reamer to mix 6.5 minutes; then add aramid fiber and flake graphite and start the reamer to mix for 0.5-1.5 minutes; store in a metal or plastic container with a cover; store it for a minimum of 1 day before use; the maximum validity period is 120 days;

[0048] (2) Compression: Use a hydraulic press and a six-cavity mold to press, adjust the temperature of the press mold to 155°C to 165°C; apply a rubber-type release agent; when pressing the mold, pressurize to 20MPa for 20 seconds, and then deflate for 5 seconds. Repeat the pressurization and deflation proces...

Embodiment 3

[0051] Wear-resistant and low-noise soft brake pads include the following raw materials by weight: 51 parts of anti-friction rubber particles, 10.5 parts of barite powder, 5 parts of artificial graphite, 3 parts of friction powder, 6 parts of coke, 3 parts of yellow vermiculite, high-temperature calcined 0.5 parts of alumina, 12 parts of flake graphite containing 94% fixed carbon, 1 part of aramid fiber, 4 parts of zircon powder, 1 part of calcium sulfate whisker, 2 parts of heavy magnesium containing 90% of magnesium, and 1 part of talcum powder.

[0052] The friction-reducing rubber particles include the following raw materials in parts by weight: 8 parts of rubber, 7 parts of reinforcing fiber, and 12 parts of thermosetting resin;

[0053] Described rubber is styrene-butadiene rubber and nitrile rubber;

[0054] The reinforcing fibers are metal fibers and carbon fibers;

[0055] The thermosetting resin is phenolic resin.

[0056] The fineness of the artificial graphite is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com