A kind of ultra-thin copper foil and preparation method thereof

An ultra-thin copper foil and metal foil technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of poor tensile strength and elongation, and the thickness of ultra-thin copper foil cannot meet the requirements, and achieve excellent performance, The preparation method is stable and controllable, and the effect of good peeling potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

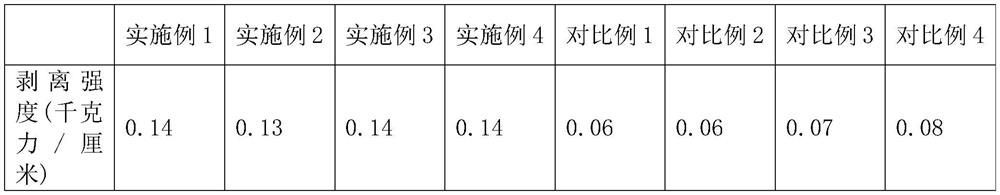

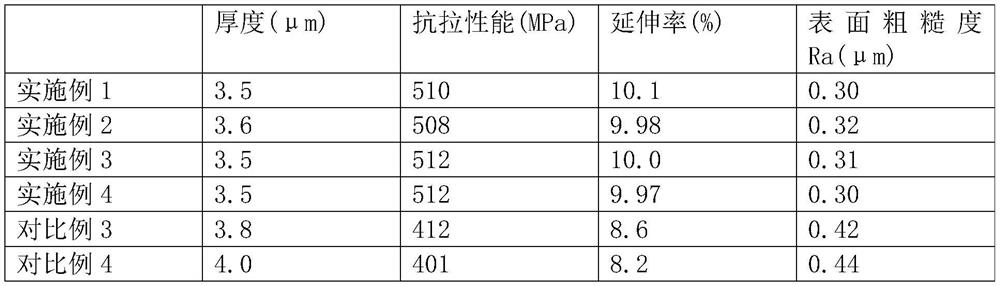

Examples

Embodiment 1

[0033] (1) Adsorb the organic layer on the surface of the copper foil carrier

[0034] Take copper foil with a thickness of 35 μm as the deposition carrier, pickle the carrier to remove oxides and impurities on the surface of the carrier, and then immerse the cleaned carrier copper foil in cyclohexyl hexaphosphoric acid and 2-thiouracil In the mixed aqueous solution (the concentration of cyclohexanehexaphosphoric acid is 1g / L, and the concentration of 2-thiouracil is 1g / L), soak at room temperature for 70s, take it out and wash it with deionized water to obtain a carrier for adsorbing the organic layer;

[0035] (2) Deposit an alloy layer on the organic layer adsorbed by the carrier

[0036] Preparation of tungsten-nickel alloy electrolyte: the concentration of nickel sulfate in the electrolyte is 20g / L, the concentration of sodium tungstate is 35g / L, the addition amount of rare earth element Pr is 0.05g / L, and the addition amount of Nd is 0.03g / L. Electrolyte pH4.5;

[0037...

Embodiment 2

[0043] (1) Adsorb the organic layer on the surface of the copper foil carrier

[0044] Take copper foil with a thickness of 35 μm as the deposition carrier, pickle the carrier to remove oxides and impurities on the surface of the carrier, and then immerse the cleaned carrier copper foil in cyclohexyl hexaphosphoric acid and 2-thiouracil In the mixed aqueous solution (the concentration of cyclohexanehexaphosphoric acid is 5g / L, and the concentration of 2-thiouracil is 5g / L), soak at room temperature for 75s, take it out and rinse it with deionized water to obtain a carrier for adsorbing the organic layer;

[0045] (2) Deposit an alloy layer on the organic layer adsorbed by the carrier

[0046] Preparation of tungsten-nickel alloy electrolyte: the concentration of nickel sulfate in the electrolyte is 22g / L, the concentration of sodium tungstate is 30g / L, the addition amount of rare earth element Pr is 0.06g / L, and the addition amount of Nd is 0.04g / L. Electrolyte pH5.0;

[004...

Embodiment 3

[0053] (1) Adsorb the organic layer on the surface of the copper foil carrier

[0054] Take copper foil with a thickness of 35 μm as the deposition carrier, pickle the carrier to remove oxides and impurities on the surface of the carrier, and then immerse the cleaned carrier copper foil in cyclohexyl hexaphosphoric acid and 2-thiouracil In the mixed aqueous solution (the concentration of cyclohexanehexaphosphoric acid is 10g / L, and the concentration of 2-thiouracil is 6g / L), soak at room temperature for 73s, take it out and rinse it with deionized water to obtain a carrier for adsorbing the organic layer;

[0055] (2) Deposit an alloy layer on the organic layer adsorbed by the carrier

[0056] Preparation of tungsten-nickel alloy electrolyte: the concentration of nickel sulfate in the electrolyte is 23g / L, the concentration of sodium tungstate is 25g / L, the addition amount of rare earth element Pr is 0.06g / L, and the addition amount of Nd is 0.04g / L. Electrolyte pH5.0;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com