Combined cavity for flow field video and aerodynamic load measurement

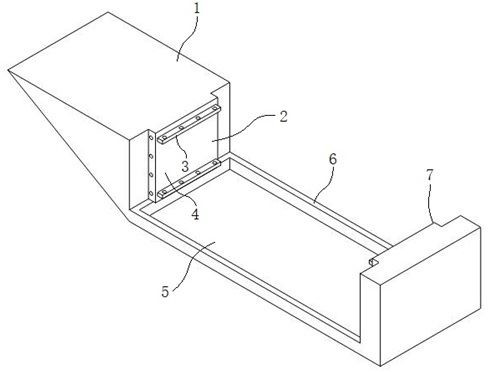

An aerodynamic load, combined technology, applied in the cross field, can solve the problem of increasing the workload of wind tunnel test, video measurement of difficult flow field structure, static pressure distribution of aerodynamic characteristics, noise load and vibration response, cavity model processing cost increase, etc. problems, to avoid processing multiple sets of models, convenient disassembly and assembly, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

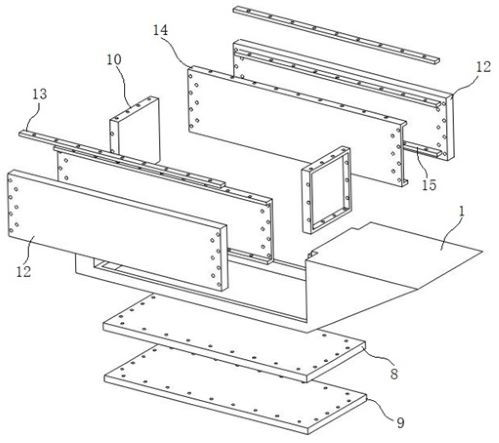

[0035] When the substrate 1 is only connected with rigid functional boards 12 on both sides of the first connecting part 2 and the second connecting part 7, the whole constructed cavity can be used for unsteady pulsating pressure measurement or oil flow test on the cavity wall surface.

Embodiment 2

[0037] When the elastic plate 14 is combined and connected to the inner wall of the functional plate 12, the entire constructed cavity can be used to study the mutual coupling characteristics of the elastic cavity wall and the noise in the cavity

Embodiment 3

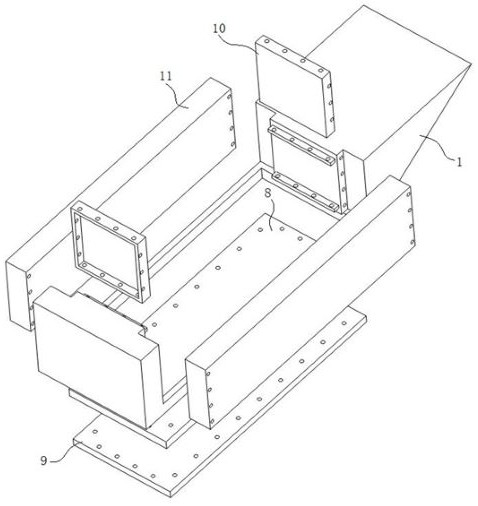

[0039] like image 3 As shown, when the functional plate 12 and the elastic plate 14 are replaced by a transparent plexiglass plate 11, the entire constructed cavity can be used to display and measure the flow structure, so that the device can be applied to PIV test, schlieren test and video measurement test etc.

[0040] The research contents of the above-mentioned embodiments have a wide range of application, and can be simultaneously applied to cavity unsteady pulsation pressure measurement test, flow display test, acoustic-vibration characteristic research and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com