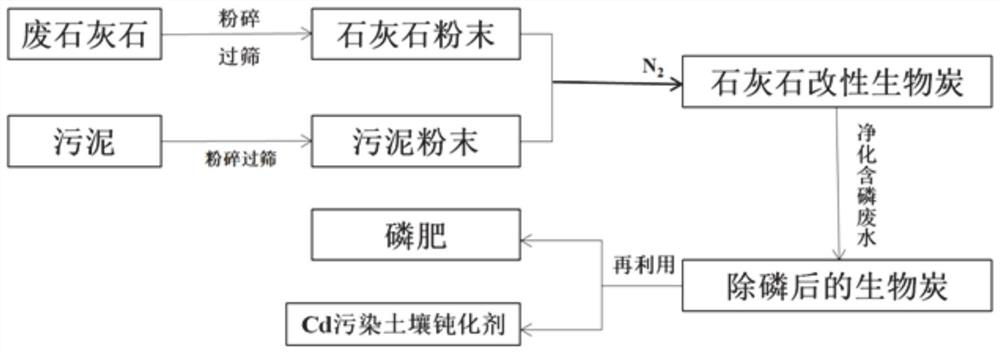

Phosphorus removal adsorbent as well as preparation method and application thereof

A phosphorus adsorbent and adsorbent technology, applied in the field of phosphorus removal adsorbent and its preparation, can solve the problems of restricting the wide application of modified materials, complicated material operation, high cost, etc., and achieve resource utilization, high phosphorus removal efficiency, and method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] ① Dry the remaining sludge from the sewage treatment plant at 105°C for 24 hours. The dried sludge is crushed through a 0.1mm sieve with a pulverizer; the limestone is washed three times with deionized water, and after drying, it is pulverized through a 0.1mm sieve with a pulverizer.

[0036] ② Mix the screened waste limestone and sludge according to the ratio of limestone to sludge dry weight of 3:1, put them into a quartz boat, and heat from room temperature at a rate of 10°C / min in a programmable tube furnace OTF-1200X to 800°C, and at 800°C N 2 Keep it under the atmosphere for 2 hours, and then wait for the powder to cool to room temperature, wash the obtained powder with deionized water to remove the residue on the surface, then place the powder in an oven at 95°C to dry, and after drying, grind it through a 0.1mm sieve. Save for later.

Embodiment 2

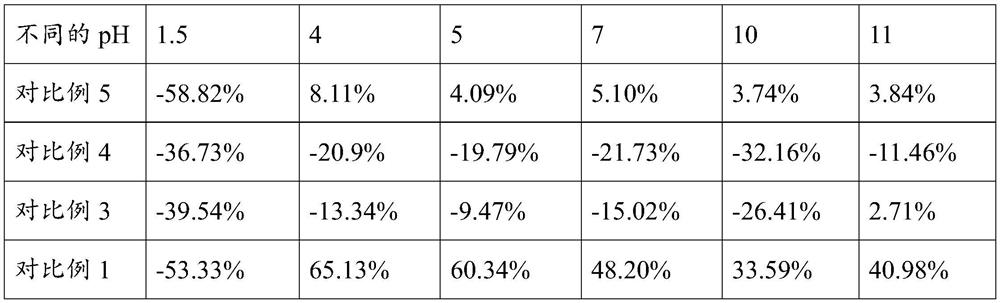

[0038] Compared with Example 1, the heating temperature in the tube furnace was 700°C.

Embodiment 3

[0040] Compared with Example 1, the heating temperature in the tube furnace was 600°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com