A new type of trapezoidal thread processing method of c/sic ceramic matrix composite material

A technology of trapezoidal threads and composite materials, applied in metal processing equipment, manufacturing tools, thread cutting machines, etc., can solve problems such as poor anisotropic thermal conductivity, service performance quality risk, small tooth structure size, etc., to achieve cutting performance and service life Improvement, excellent cutting matching, and high tooth root strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

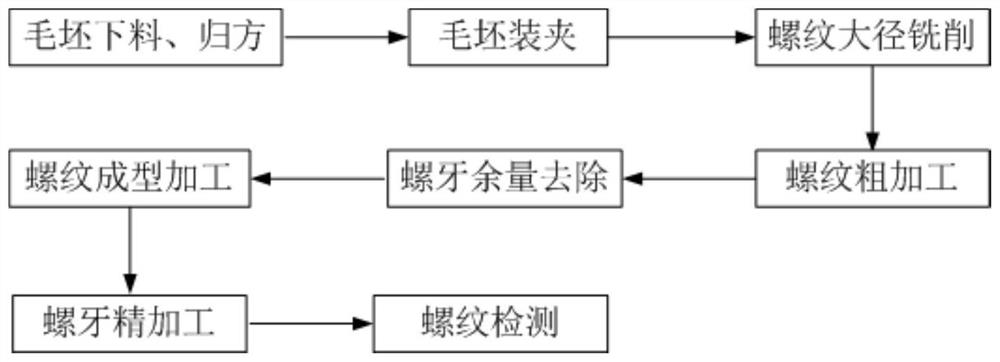

[0047] The processing object is the Tr8×1.5-7e threaded connection of orthogonal three-directional C-fiber C / SiC ceramic matrix composite material, and the processing method is copying dry cutting.

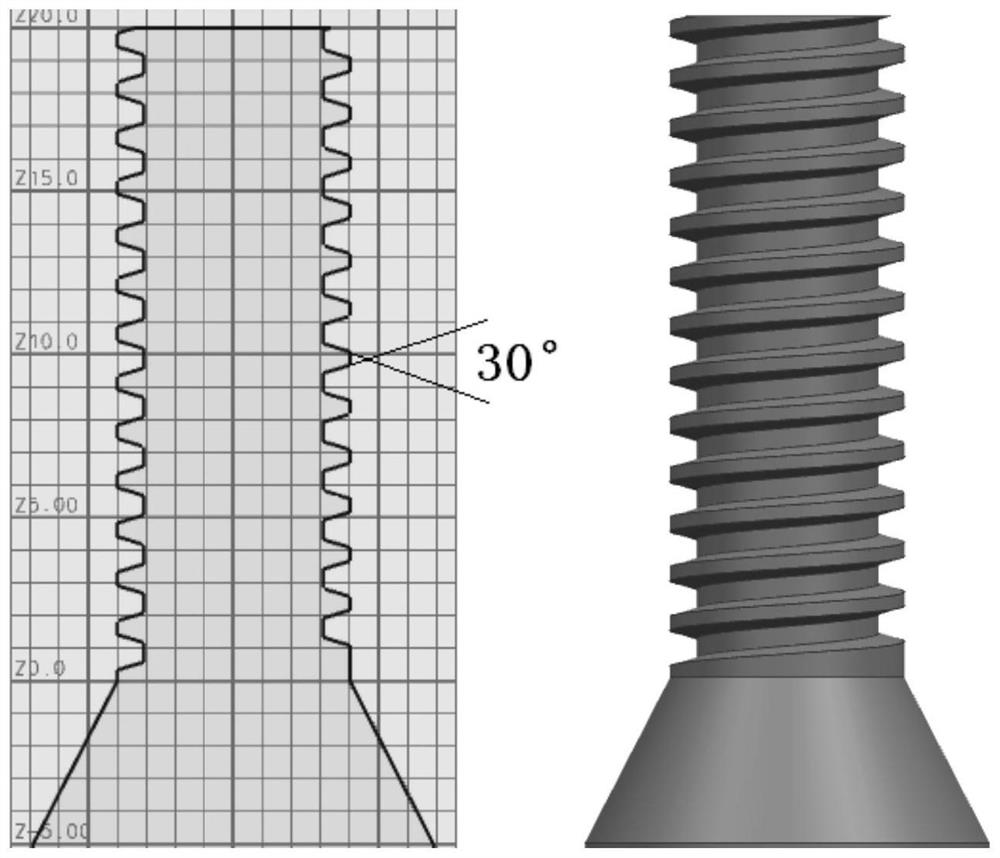

[0048] (1) Design a metric trapezoidal thread structure with an angle of 30°, an accuracy of 7e, and a major diameter of The trail is The thread direction is right hand.

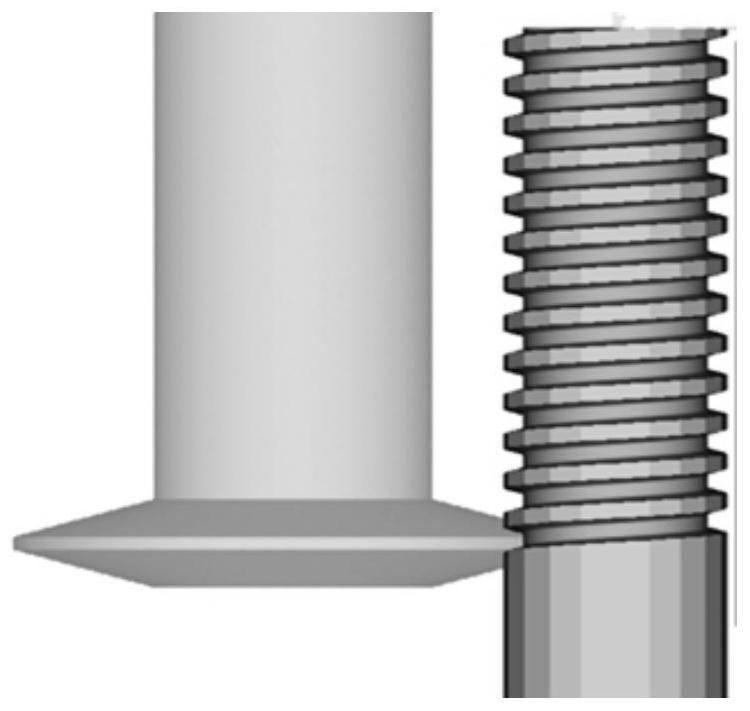

[0049] (2) Design and manufacture integral diamond variable diameter round nose milling cutter and electroplated diamond thread milling cutter. Among them, the structure of the integral diamond round nose milling cutter is an integral type. The base of the tool holder is made of nano-tungsten carbide-cobalt carbide, the blade is made of synthetic polycrystalline diamond (PCD), and the blade and the holder are made of high frequency induction brazing. The diameter is Φ9.75mm, the rotating diameter of the blade is Φ10mm, the number of blades is 2, and the corner R of the blade tip is 0.798mm. The diamond raw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com