Environment-friendly deodorant and preparation method thereof

An environmentally friendly deodorant and deodorant technology, which is applied in the fields of botanical equipment and methods, chemical instruments and methods, biocides, etc., can solve the problems of low efficiency of deodorization methods, poor removal effect of odorous gas in circulating water, and insufficient raw materials. Environmental protection and other issues, to achieve the effect of improving deodorization effect, good chemical stability and biocompatibility, and inhibiting the production of odor molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

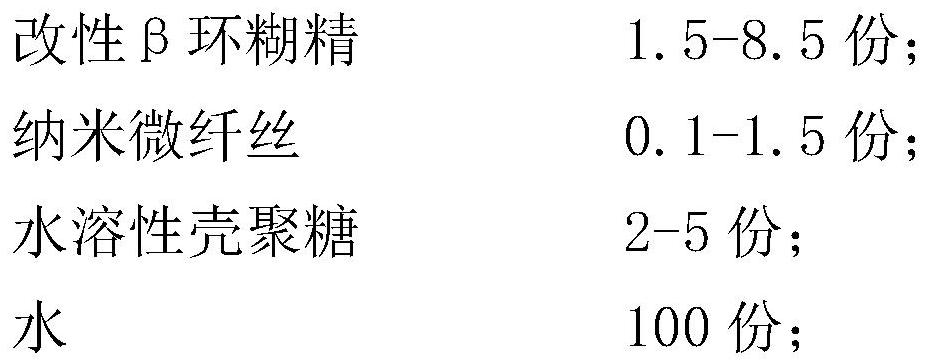

Method used

Image

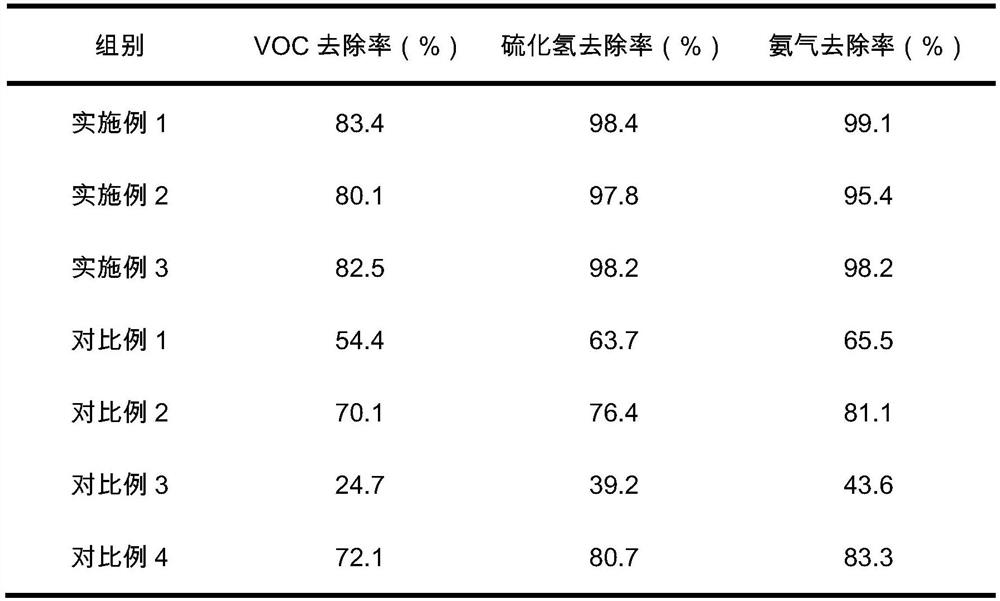

Examples

Embodiment 1

[0043] Step 1: Take 100 parts of water and heat it to 60°C, then add 20 parts of β-cyclodextrin, adjust the pH value of the water body to 10 with 30% sodium hydroxide, and stir with a stirrer for 10 minutes. Then add 20 parts of cationic etherifying agent 3-chloro-2-hydroxypropyl-trimethylammonium chloride, stir for 4 minutes with a stirrer at 800 r / min, and shake for 10 minutes with a 300 kHz ultrasonic cleaner. Then use a microwave frequency of 2450MHz to heat for 6 minutes, and then add hydrochloric acid after standing for 8 minutes to adjust the pH to 6.9. The solution was vacuum-dried at 70°C for 10 h, and the resulting dried product was dissolved in 20 parts of N,N-dimethylformamide. 200 parts of acetone were added to the solution, and the obtained precipitate was vacuum-dried at 50° C. for 15 hours to obtain modified β-cyclodextrin.

[0044] Step 2: Take 100 parts of water, add 1 part of hardwood fiber, and use a deflagging machine to decompose at a speed of 20,000 rpm...

Embodiment 2

[0047] Step 1: Take 100 parts of water and heat it to 40°C, then add 5 parts of β-cyclodextrin, adjust the pH value of the water body to 8 with 30% sodium hydroxide, and stir with a stirrer for 5 minutes. Then add 4 parts of cationic etherification agent 2,3-epoxypropyltrimethylammonium chloride, stir for 2 minutes with a stirrer at a speed of 300 r / min, and shake for 5 minutes with a 300 kHz ultrasonic cleaner. Then use a microwave frequency of 2450MHz to heat for 2 minutes, and then add hydrochloric acid after standing for 5 minutes to adjust the pH to 6.5. The solution was vacuum-dried at 60°C for 8 hours, and the resulting dried product was dissolved in 10 parts of N,N-dimethylformamide. Add 100 parts of acetone to the solution, and then vacuum-dry the obtained precipitate at 40°C for 10 hours to obtain modified β-cyclodextrin.

[0048] Step 2: Take 100 parts of water, add 0.5 part of coniferous wood fiber, and use a deflagging machine to decompose at a speed of 10,000 rp...

Embodiment 3

[0051] Step 1: Take 100 parts of water and heat it to 80°C, then add 30 parts of β-cyclodextrin, adjust the pH value of the water body to 11 with potassium hydroxide with a mass fraction of 30%, and stir with a stirrer for 15 minutes. Then add 25 parts of cationic etherifying agent 3-chloro-2-hydroxypropyl-trimethylammonium chloride, stir for 5 minutes with a stirrer at a speed of 1000 r / min, and shake for 15 minutes with a 300 kHz ultrasonic cleaner. Then use a microwave frequency of 2450MHz to heat for 10 minutes, and then add hydrochloric acid after standing for 10 minutes to adjust the pH to 7.0. The solution was vacuum-dried at 80°C for 15 hours, and the resulting dried product was dissolved in 25 parts of N,N-dimethylformamide. Add 300 parts of acetone to the solution, and then vacuum-dry the obtained precipitate at 60° C. for 20 hours to obtain modified β-cyclodextrin.

[0052] Step 2: Take 100 parts of water, add 1.5 parts of cotton fiber, and use a deflagging machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com