Modified paper-plastic composite adhesive and preparation method thereof

A technology of composite adhesive and modified paper, applied in the field of adhesive materials, can solve the problems of plastic film opening and foaming, poor bonding effect, poor environmental protection, etc. and the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

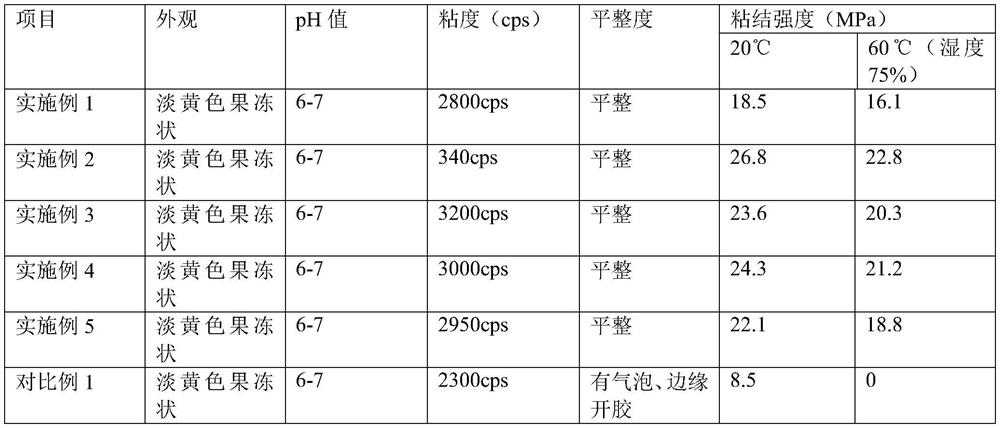

Examples

Embodiment 1

[0025] A modified paper-plastic composite glue, comprising 40 parts by weight of hide glue, 15 parts of maltose, 10 parts of superfine talcum powder with a particle size of 0.5-1 μm, 0.1 part of transglutaminase, 0.1 part of collagenase, 30 parts of water.

[0026] A preparation method of modified paper-plastic composite glue, comprising the following steps:

[0027] (S.1) Put hide glue and maltose in water, heat up to 50°C to dissolve, then add superfine talc powder to form a stable colloid;

[0028] (S.2) Adjust the temperature of the colloid to 35°C, add transglutaminase to the colloid, and stir the enzymolysis for 30 minutes to obtain a primary enzymatic hydrolyzate;

[0029] (S.3) Add collagenase to the first enzymatic hydrolyzate, enzymatically hydrolyze at 35°C for 15 minutes, then raise the temperature to 70°C, keep for 10 minutes to inactivate the enzyme, and naturally cool to room temperature to obtain the modified paper-plastic composite glue .

Embodiment 2

[0031] A modified paper-plastic composite glue, comprising 60 parts by weight of bone glue, 30 parts of maltose, 25 parts of superfine talcum powder with a particle size of 0.5-2 μm, 0.5 part of glutamine transaminase, 0.5 part of collagenase, water 40 parts and 5 parts boric acid.

[0032] A preparation method of modified paper-plastic composite glue, comprising the following steps:

[0033] (S.1) Put bone glue and maltose in water, heat up to 65°C to dissolve, then add ultra-fine talc powder to form a stable colloid;

[0034] (S.2) Adjust the temperature of the colloid to 42°C, add transglutaminase to the colloid, and stir for 45 minutes for enzymolysis to obtain a primary enzymatic hydrolyzate;

[0035] (S.3) Add collagenase to the first enzymatic hydrolyzate, 40°C, enzymolysis for 30 minutes, add boric acid, raise the temperature to 75°C, keep for 30 minutes to inactivate the enzyme, naturally cool to room temperature to obtain modified paper Plastic compound.

Embodiment 3

[0037] A modified paper-plastic composite glue, comprising 50 parts by weight of gelatin, 20 parts of maltose, 15 parts of superfine talcum powder with a particle diameter of 5-10 μm, 0.3 parts of glutamine transaminase, 0.3 parts of collagenase, water 35 parts and 3 parts of trimethyl borate.

[0038] A preparation method of modified paper-plastic composite glue, comprising the following steps:

[0039] (S.1) Put gelatin and maltose in water, heat up to 60°C to dissolve, then add ultra-fine talc powder to form a stable colloid;

[0040] (S.2) Adjust the temperature of the colloid to 38°C, add transglutaminase to the colloid, and stir for 40 minutes for enzymolysis to obtain a primary enzymatic hydrolyzate;

[0041] (S.3) Add collagenase to the first enzymatic hydrolyzate, hydrolyze at 40°C for 20 minutes, add trimethyl borate, raise the temperature to 72°C, keep for 20 minutes to inactivate the enzyme, and naturally cool to room temperature to obtain Modified paper-plastic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com