Preparation method and application of core-shell structure indium cadmium sulfide@N-titanium dioxide composite photocatalyst

A technology of indium cadmium sulfide and titanium dioxide, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems that Ti-O clusters are not stable, affect the catalytic effect of materials, etc., and meet the preparation conditions Easy to control, simple and easy to prepare, good photocatalytic degradation activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) NH 2 - Preparation of MIL-125(Ti): 1.2681 g of 2-aminoterephthalic acid (6 mmol, TCI, 98%) and titanium isopropoxide (3 mmol) were dissolved in DMF (N-N dimethylformamide) (25 ml, DMF) and anhydrous methanol solvent (25ml, CH 3 OH, 99.8%), the mixture was stirred for 30 minutes to obtain a homogeneous mixture, the mixture was transferred to a polytetrafluoroethylene stainless steel autoclave, and kept at 150° C. for 24 h. After the mixture was cooled to room temperature, the yellow NH 2 - MIL-125, rinsed several times with anhydrous methanol and DMF, dried overnight in an oven at 200°C for 6 hours.

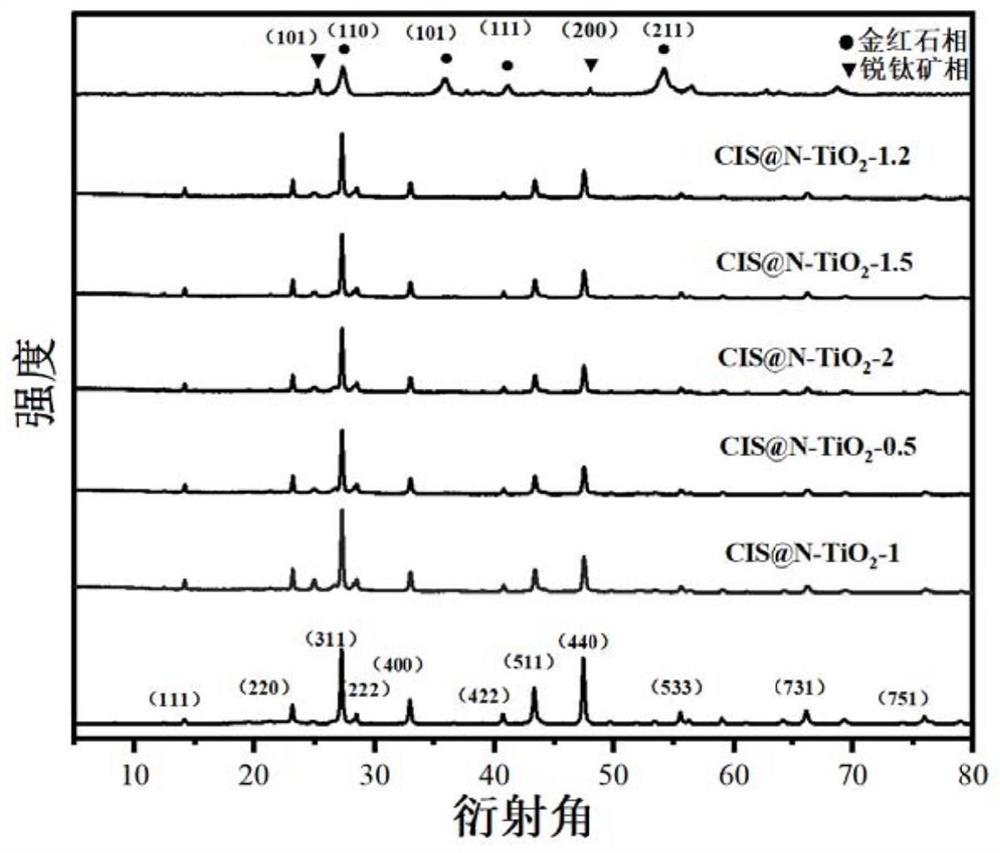

[0031] (2) NH 2 - N-TiO derived from MIL-125(Ti) 2 Preparation: the NH obtained in step (1) 2 -MIL-125(Ti) was calcined for 6h at 500°C under a nitrogen atmosphere to obtain N-TiO 2 .

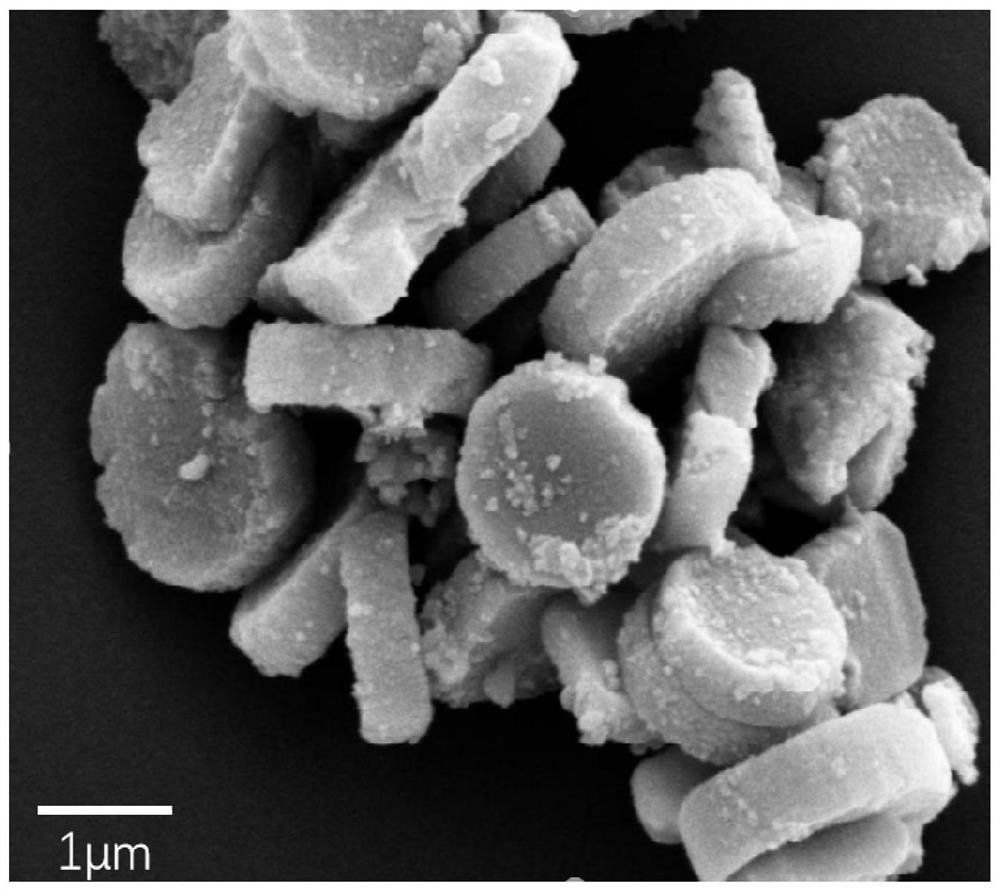

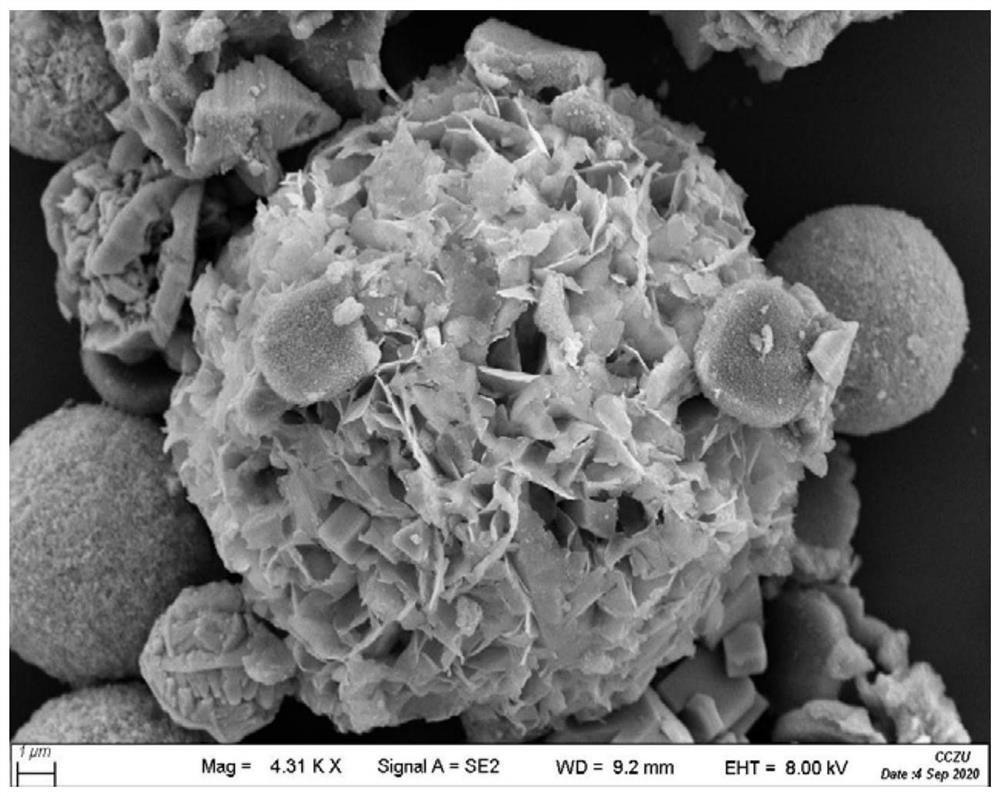

[0032] (3) Preparation of indium cadmium sulfide@N-titanium dioxide composite photocatalyst: N-TiO 2(0.056g) was dispersed in 30ml of water containing cadmium chloride (1mmol) an...

Embodiment 2

[0034] (1) NH 2 - Preparation of MIL-125(Ti): 1.2681 g of 2-aminoterephthalic acid (6 mmol, TCI, 98%) and titanium isopropoxide (3 mmol) were dissolved in DMF (N-N dimethylformamide) (25 ml, DMF) and anhydrous methanol solvent (25ml, CH 3 OH, 99.8%), the mixture was stirred for 30 minutes to obtain a homogeneous mixture, the mixture was transferred to a polytetrafluoroethylene stainless steel autoclave, and kept at 150° C. for 24 h. After the mixture was cooled to room temperature, the yellow NH 2 - MIL-125, rinsed several times with anhydrous methanol and DMF, dried overnight in an oven at 200°C for 6 hours.

[0035] (2) NH 2 - N-TiO derived from MIL-125(Ti) 2 Preparation: the NH obtained in step (1) 2 -MIL-125(Ti) was calcined for 6h at 500°C under a nitrogen atmosphere to obtain N-TiO 2 .

[0036] (3) Preparation of indium cadmium sulfide@N-titanium dioxide composite photocatalyst: N-TiO 2 (0.08g) was dispersed in 30ml of water containing cadmium chloride (1mmol) a...

Embodiment 3

[0038] (1) NH 2 - Preparation of MIL-125(Ti): 1.2681 g of 2-aminoterephthalic acid (6 mmol, TCI, 98%) and titanium isopropoxide (3 mmol) were dissolved in DMF (N-N dimethylformamide) (25 ml, DMF) and anhydrous methanol solvent (25ml, CH 3 OH, 99.8%), the mixture was stirred for 30 minutes to obtain a homogeneous mixture, the mixture was transferred to a polytetrafluoroethylene stainless steel autoclave, and kept at 150° C. for 24 h. After the mixture was cooled to room temperature, the yellow NH 2 - MIL-125, rinsed several times with anhydrous methanol and DMF, dried overnight in an oven at 200°C for 6 hours.

[0039] (2) NH 2 - N-TiO derived from MIL-125(Ti) 2 Preparation: the NH obtained in step (1) 2 -MIL-125(Ti) was calcined for 6h at 500°C under a nitrogen atmosphere to obtain N-TiO 2 .

[0040] (3) Preparation of indium cadmium sulfide@N-titanium dioxide composite photocatalyst: N-TiO 2 (0.096g) was dispersed in 30ml of water containing cadmium chloride (1mmol) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com