Process for treating high-concentration nitrate and ammonia-nitrogen wastewater by using sludge fermentation liquor as carbon source through series connection of short-cut denitrification and anaerobic ammonia oxidation

A short-range denitrification, anaerobic ammonium oxidation technology, applied in anaerobic digestion treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of increasing sludge treatment and disposal costs and energy consumption, Consumption of organic carbon sources, inability to meet denitrification and other problems, to achieve stable short-range denitrification nitrite accumulation rate, achieve sludge reduction, and save sludge disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

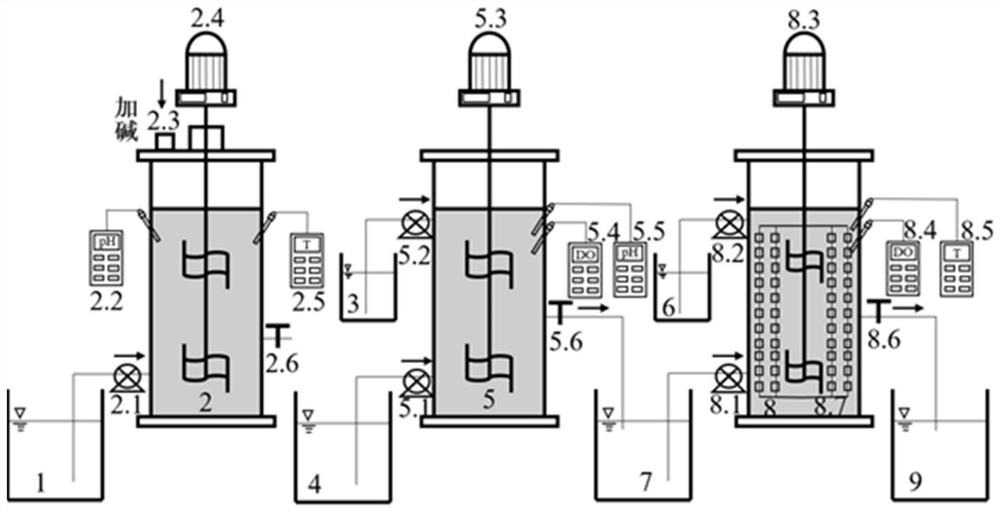

[0027] like figure 1As shown, the process of short-range denitrification and anaerobic ammonium oxidation treatment of high-concentration nitrate and ammonia nitrogen wastewater is realized using sludge fermentation liquid as a carbon source. The equipment used includes a mud storage tank (1), a sludge fermentation tank (2), a fermentation Liquid water tank (3), nitrate waste water tank (4), PD-SBR reactor (5), ammonia nitrogen waste water tank (6), intermediate water tank (7), AMX-SBR reactor (8), effluent water tank (9) ; It is characterized in that the remaining sludge in the mud storage box (1) is pumped into the sludge fermentation tank (2) through the first peristaltic pump (2.1), and the sludge fermentation mixture is discharged through the first sludge discharge valve (2.6), After centrifugation, it enters the fermentation liquid water tank (3); the waste water in the nitrate waste water tank (4) is pumped into the PD-SBR reactor (5) through the second peristaltic pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com