Hospital sewage treatment method

A sewage treatment method and hospital technology, which can be used in water/sewage treatment, biological water/sewage treatment, heating water/sewage treatment, etc., and can solve problems such as low removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

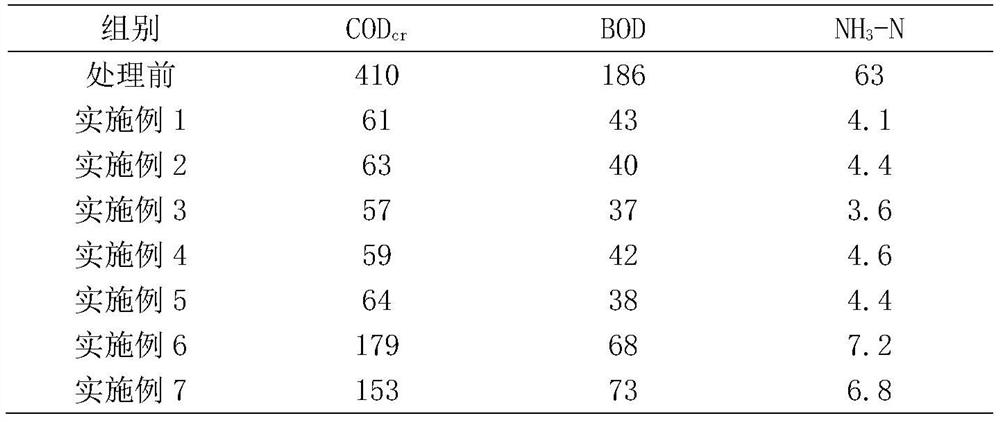

Examples

Embodiment 1

[0022] The present embodiment provides a kind of hospital sewage treatment method, comprises the following steps:

[0023] S1. Sewage Sterilization: After the sewage produced in the hospital is collected, it is continuously sterilized by a tubular sterilizer to obtain sterilized wastewater; the sterilization temperature is 135°C.

[0024] S2, microbial treatment: cooling the wastewater after sterilizing treatment, adding microorganisms to the cooled wastewater, the addition of the microorganisms is 6% of the wastewater weight; 2 days of treatment; the microorganisms are Flavobacterium sea mud, Bacillus subtilis , Rhizopus niger, Esterogenic yeast, Bifidobacterium, Mucor racemosa and Mucor ruckeri, the weight ratio is 5:0.5:1:3:1:1:2.

[0025] S3. Centrifugal separation: use a continuous flow centrifuge to centrifuge the waste water after the microbial treatment in step S2, and discharge the clear liquid to the flocculation tank after centrifugation, and kill the bacteria in a ...

Embodiment 2

[0030] The present embodiment provides a kind of hospital sewage treatment method, comprises the following steps:

[0031] S1. Sewage Sterilization: After the sewage produced in the hospital is collected, it is continuously sterilized by a tubular sterilizer to obtain sterilized wastewater; the sterilization temperature is 110°C.

[0032] S2, microbial treatment: cooling the wastewater after sterilizing treatment, adding microorganisms to the cooled wastewater, the addition of the microorganisms is 1% of the wastewater weight; 5 days of treatment; the microorganisms are Flavobacterium sea mud, Bacillus subtilis , Rhizopus niger, Esterogenic yeast, Bifidobacterium, Mucor racemosa and Mucor ruckeri, the weight ratio is 1:2:2:1:0.5:5:1.

[0033] S3. Centrifugal separation: use a continuous flow centrifuge to centrifuge the waste water after the microbial treatment in step S2, and discharge the clear liquid to the flocculation tank after centrifugation, and kill the bacteria in a ...

Embodiment 3

[0038] The present embodiment provides a kind of hospital sewage treatment method, comprises the following steps:

[0039] S1. Sewage Sterilization: After the sewage produced in the hospital is collected, it is continuously sterilized by a tubular sterilizer to obtain sterilized wastewater; the sterilization temperature is 121°C.

[0040] S2, microbial treatment: the waste water after sterilizing treatment is cooled, and microorganism is added in the waste water after cooling, and the addition amount of described microorganism is 5% of waste water weight; Treat for 3 days; Microbe is sea mud Flavobacterium, Bacillus subtilis , Rhizopus niger, Esterogenic yeast, Bifidobacterium, Mucor racemosa and Mucor ruckeri, the weight ratio is 3:1:2:1:0.5:5:1.

[0041] S3. Centrifugal separation: use a continuous flow centrifuge to centrifuge the waste water after the microbial treatment in step S2, and discharge the clear liquid to the flocculation tank after centrifugation, and kill the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com