Method for synchronously removing ammonia nitrogen in river sediment and overlying water body by using ammonia nitrogen release increasing agent

A technology of river sediment and release agent, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc. Eliminate problems such as river eutrophication, and achieve the effects of low preparation cost, good market prospect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

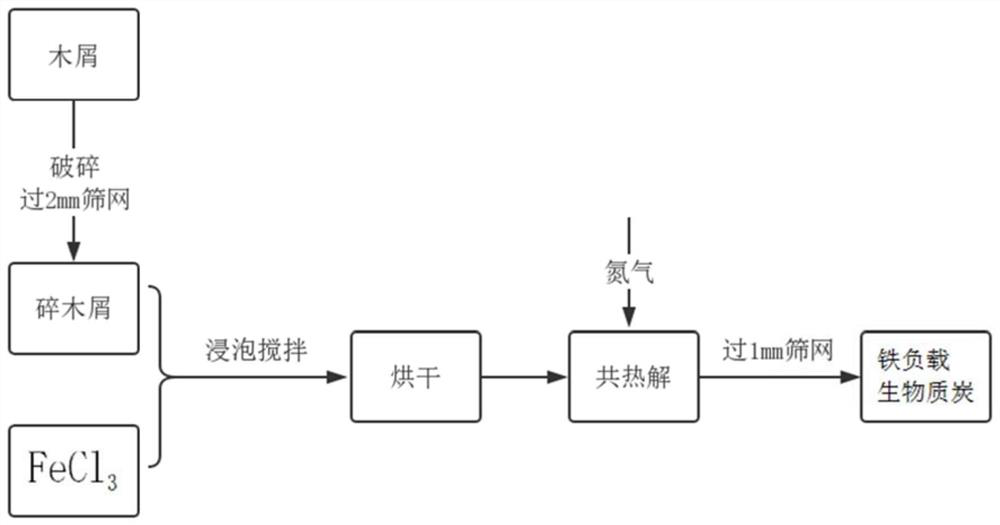

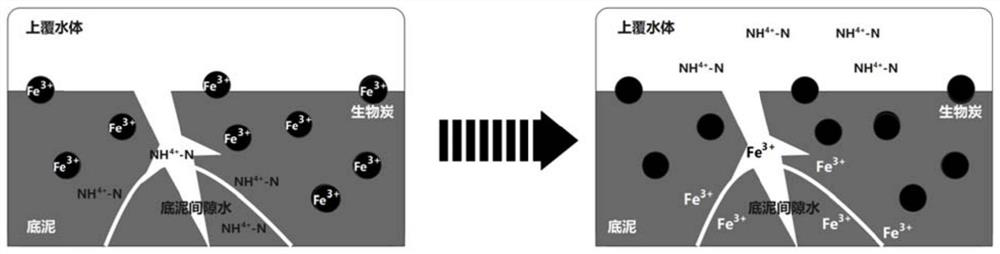

[0053] In another embodiment, the preparation method of described iron-loaded biochar comprises the following steps:

[0054] (a) Sieve the sawdust and mix with FeCl 3 The solution was mixed and soaked, stirred and soaked at room temperature, so that Fe 3+ Fully and evenly loaded on the surface of biomass, and then dried to constant weight;

[0055] (b) Co-pyrolyze the dried mixture under an inert gas atmosphere, and cool naturally to room temperature to obtain iron-loaded biochar, which is sieved for later use.

[0056] In another embodiment, FeCl 3 The concentration of the solution is 10~50mg L -1 , FeCl 3 The solution is fully mixed with wood chips, and the mixing specific gravity is FeCl 3 The solution accounts for 15-25wt% of wood chips.

[0057] In another embodiment, in step (a), drying is carried out at 40°C.

[0058] In another embodiment, in step (b), during co-pyrolysis: at 5-15°C min -1 The heating rate is increased to 450~550°C, and then stay for 1~3h; the...

Embodiment 1

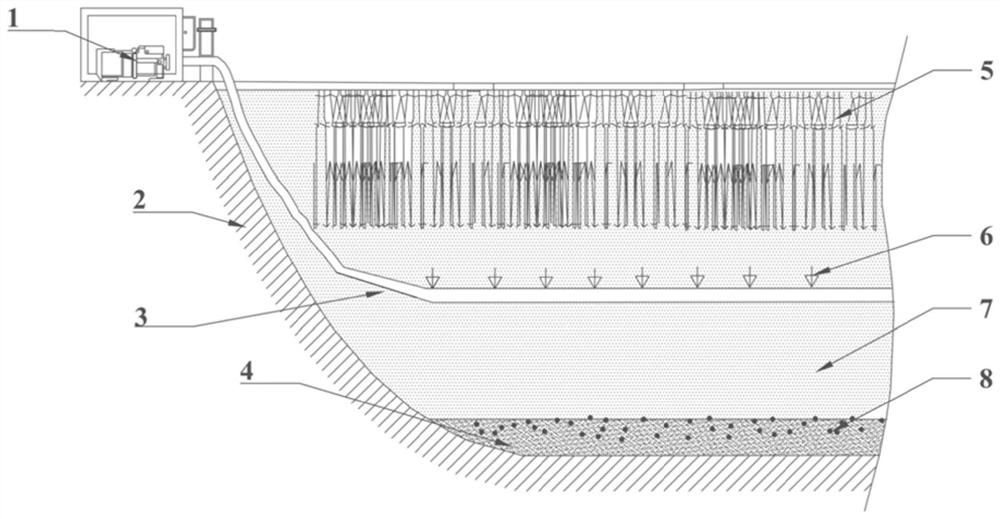

[0068] In this embodiment, the method of synchronously removing ammonia nitrogen from the river sediment and the overlying water body using the ammonia nitrogen release agent adopts the following steps:

[0069] (1) figure 1 Flowchart for the preparation of the bottom sludge ammonia nitrogen release agent (iron-loaded biochar), pass the wood chips through a 2-mm sieve, and mix with FeCl 3 Solution (30mg L -1 ) mixed soaking, FeCl 3 The mixing ratio of the solution and the wood chips is 20wt%, and the OS40-S cantilever electric stirrer is used to stir and soak for 2 hours at room temperature, and the speed is 50r min -1 , the purpose is to make Fe 3+ Fully and evenly loaded on the surface of biomass; use HY TECH-HY5210 blast drying oven to dry the above samples to constant weight at 40°C.

[0070] (2) Put 20g of drying mixture in a quartz boat with a length of 10cm and a radius of 2cm, place the quartz boat in the quartz tube of the OTF-1200X-S small-scale high-temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com