A kind of natural polymer fluid loss reducer

A technology of natural polymer and filtrate reducer, which is applied in the field of natural polymer fluid loss reducer and its preparation, can solve the problems of poor heat resistance of xanthan gum, etc., to increase the success rate of grafting, improve the tolerance and Good stability and anti-filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

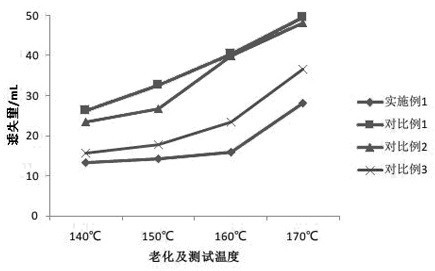

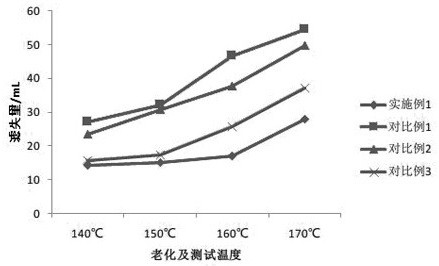

Examples

Embodiment 1

[0057] Preparation of natural polymer fluid loss reducer:

[0058] S1. take by weighing the grafting agent 50 weight parts that are made up of maleimide, sodium p-styrenesulfonate and add 500 weight parts of water, wherein the mass ratio of maleimide and sodium p-styrenesulfonate is 1: 1.5, and an appropriate amount of sodium hydroxide solution to adjust the solution to be alkaline and set aside;

[0059] S2. Weigh 0.05 parts by weight of dicumyl peroxide (DCP) and 0.01 parts by weight of N,N-methylenebisacrylamide as a crosslinking agent, set aside;

[0060] S3. take potassium persulfate and water, be made into the solution that mass fraction is 0.5% as initiator, stand-by;

[0061] S4. Take by weighing 1.2 parts by weight of xanthan gum and 100 parts by weight of water and place them in the reaction vessel for mixing. The resulting mixed solution is subjected to high-speed shear processing to prepare xanthan gum solution. If the temperature is high enough to cause the degr...

Embodiment 2

[0065] Preparation of natural polymer fluid loss reducer:

[0066] S1. take by weighing grafting agent 60 weight parts that are made up of maleimide, sodium p-styrenesulfonate and add 600 weight parts of water, wherein the mass ratio of maleimide and sodium p-styrenesulfonate is 1: 2, and an appropriate amount of potassium hydroxide solution to adjust the solution to be alkaline, and set aside;

[0067] S2. Weigh 0.17 parts by weight of dicumyl peroxide (DCP) and 0.03 parts by weight of N,N-methylenebisacrylamide as a crosslinking agent for use;

[0068] S3. take potassium persulfate and water, be made into the solution that mass fraction is 0.5% as initiator, stand-by;

[0069] S4. Weigh 1.5 parts by weight of xanthan gum and 150 parts by weight of water and place them in a reaction vessel for mixing, then carry out high-speed shearing treatment to the resulting mixed solution, and at the same time, in order to prevent high-speed shearing from increasing the temperature, the...

Embodiment 3

[0073] Preparation of natural polymer fluid loss reducer:

[0074] S1. take by weighing the grafting agent 55 weight parts that are made up of maleimide, sodium p-styrene sulfonate and add 550 weight parts of water, wherein the mass ratio of maleimide and sodium p-styrene sulfonate is 3: 4, and an appropriate amount of sodium hydroxide solution to adjust the solution to be alkaline, and set aside;

[0075] S2. Weigh 0.12 parts by weight of dicumyl peroxide (DCP) and 0.03 parts by weight of N,N-methylenebisacrylamide as a crosslinking agent for use;

[0076] S3. take potassium persulfate and water, be made into the solution that mass fraction is 0.5% as initiator, stand-by;

[0077] S4. Weigh 1.2 parts by weight of xanthan gum and 120 parts by weight of water and place them in a reaction vessel for mixing, then carry out high-speed shearing treatment to the resulting mixed solution, and at the same time, in order to prevent high-speed shearing from increasing the temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com