PC/ABS alloy material based on waste regeneration and preparation process thereof

A technology of alloy material and preparation process, which is applied in the field of waste alloy plastic preparation, can solve problems such as environmental damage, economic loss, waste of production resources, etc., and achieve the effects of increasing material life, improving processing performance, and slowing down degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

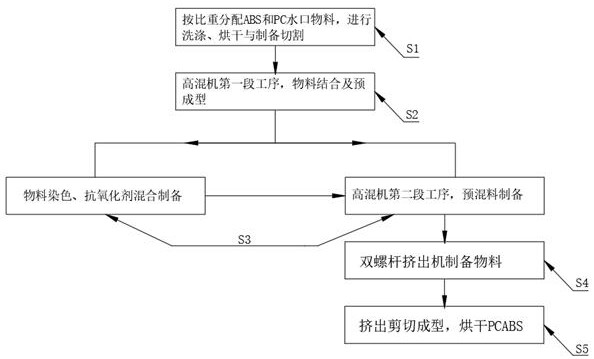

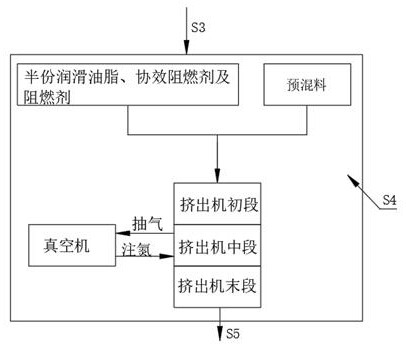

[0031] see Figure 1-2 , the present invention provides a technical solution: a PC / ABS alloy material based on waste regeneration, the alloy material is composed of the following raw materials, the raw materials are in parts by weight: 60 parts of ABS nozzle waste, 20 parts of PC nozzle waste, 3 parts Toughening agent, 5 parts of compatibilizer, 0.2 parts of antioxidant, 2 parts of synergistic flame retardant, 1 part of flame retardant, 5 parts of black masterbatch, 0.1 part of lubricating grease, 0.5 parts of anti-dripping agent, 10 parts of hardness improvement agent, 7 parts impact modifier and 3 parts pigment.

[0032] In this example, specifically: the synergistic flame retardant is halloysite, talcum powder, mica, kaolin and wollastonite in a ratio of 1:3:3:2 to make powder; the synergistic flame retardant is used Due to the synergistic flame retardant and auxiliary anti-dripping effect, on the premise that the toughness of the material is not affected, not only the fla...

Embodiment 2

[0047] see Figure 1-2 , the present invention also provides a technical solution: a PC / ABS alloy material based on waste regeneration, the alloy material is made up of the following raw materials, the raw materials are in parts by weight: 70 parts of ABS nozzle waste, 30 parts of PC nozzle waste, 4 1 part toughening agent, 6 parts compatibilizer, 0.3 part antioxidant, 3 parts synergistic flame retardant, 2 parts flame retardant, 6 parts black masterbatch, 0.2 part lubricating grease, 0.6 part anti-dripping agent, 12 parts hardness Modifier, 9 parts Impact Modifier, and 4 parts Pigment.

[0048] In this embodiment, specifically: the synergistic flame retardant is halloysite, talc powder, mica, kaolin and wollastonite, which are blended and powdered in a ratio of 1:3:3:2.

[0049] In this embodiment, specifically: the compatibilizer is maleic anhydride MAH grafted POE.

[0050] In this embodiment, specifically: the toughening agent is methyl methacrylate-butadiene-styrene gra...

Embodiment 3

[0063] see Figure 1-2 , the present invention also provides a technical solution: a PC / ABS alloy material based on waste regeneration, the alloy material is made up of the following raw materials, the raw materials are in parts by weight: 80 parts of ABS nozzle waste, 40 parts of PC nozzle waste, 5 1 part of toughening agent, 8 parts of compatibilizer, 0.4 part of antioxidant, 4 parts of synergistic flame retardant, 3 parts of flame retardant, 7 parts of black masterbatch, 0.3 part of lubricating grease, 0.7 part of anti-dripping agent, 15 parts of hardness Modifier, 13 parts Impact Modifier, and 5 parts Pigment.

[0064] In this embodiment, specifically: the synergistic flame retardant is halloysite, talc powder, mica, kaolin and wollastonite, which are blended and powdered in a ratio of 1:3:3:2.

[0065] In this embodiment, specifically: the compatibilizer is maleic anhydride MAH grafted POE, PE graft, SVN, methyl acrylate-glycidyl methacrylate copolymer.

[0066] In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com