A kind of carbon fiber electrostatic flocking fabric for realizing high-efficiency photo-steam conversion and preparation method thereof

An electrostatic flocking, carbon fiber technology, applied in textiles, papermaking, coatings, etc., can solve the problems of durability and repeated use performance, low utilization of solar energy, and difficulty in large-scale use. Transformation efficiency, strong operability and designability, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

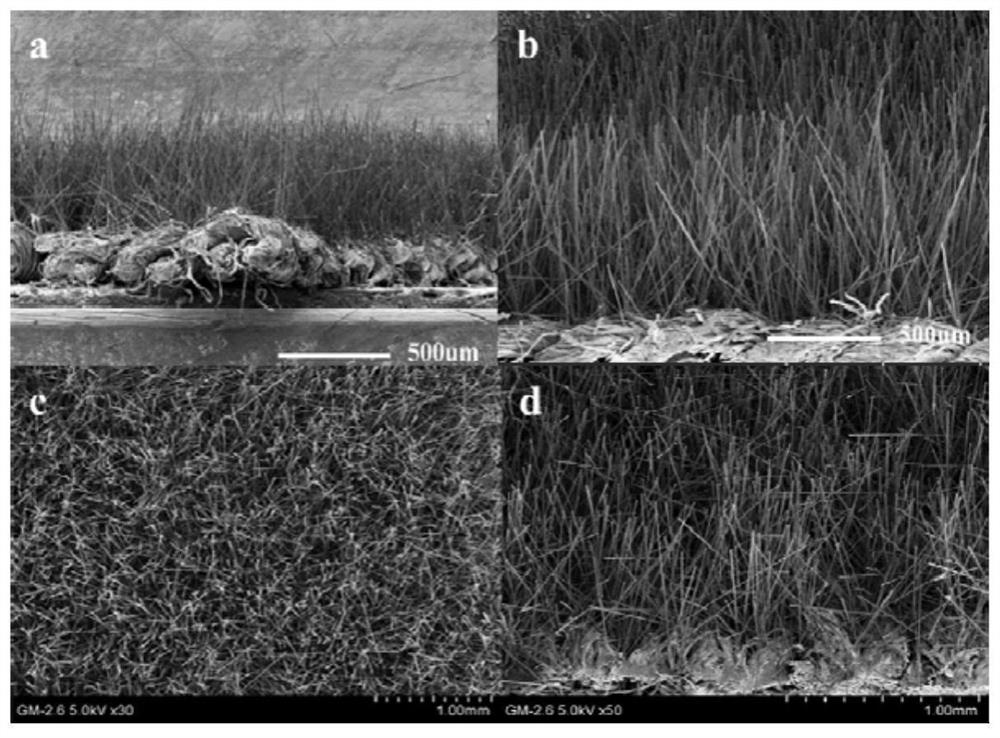

[0046] A preparation method of carbon fiber electrostatic flocking fabric for realizing high-efficiency photo-steam conversion, the specific steps are as follows:

[0047] (1) the cotton fabric is ironed and finished, and its surface is coated with chitosan glue with a thickness of 0.1 mm;

[0048] (2) Under the protection of nitrogen, the carbon fiber bundles with a length of 0.5 mm were calcined at a temperature of 400 ° C for 1 h in a tube furnace, and the surface colloid was removed to make single carbon fibers;

[0049] (3) In the flocking chamber, place the carbon fiber in the single state prepared in step (2) on the lower electrode plate that is connected to static electricity; fix the cotton fabric coated with chitosan glue obtained in step (1) on the upper electrode On the upper plate, the ground wire of the upper plate, under the working state, the carbon fibers on the lower plate are neatly implanted on the surface of the cotton fabric coated with chitosan glue on t...

Embodiment 2

[0053] A preparation method of carbon fiber electrostatic flocking fabric for realizing high-efficiency photo-steam conversion, the specific steps are as follows:

[0054] (1) the polyester-cotton fabric is ironed and finished, and its surface coating thickness is the hydroxymethyl cellulose viscose of 0.1mm;

[0055] (2) Under nitrogen protection, carbon fiber bundles with a length of 1 mm are calcined at a temperature of 430 ° C for 1 h in a tube furnace to remove surface colloids to make single carbon fibers;

[0056] (3) In the flocking chamber, place the carbon fiber in the single state prepared in step (2) on the lower electrode plate that is connected to static electricity; The fabric is fixed on the upper plate, and the upper plate is grounded. In the working state, the carbon fibers on the lower plate are neatly implanted into the upper plate coated with hydroxymethyl cellulose adhesive under the action of high-voltage static electricity. The surface of polyester-cot...

Embodiment 3

[0060] A preparation method of carbon fiber electrostatic flocking fabric for realizing high-efficiency photo-steam conversion, the specific steps are as follows:

[0061] (1) The viscose fiber fabric is ironed and finished, and its surface is coated with an acrylate adhesive with a thickness of 0.1 mm;

[0062] (2) Under the protection of nitrogen, the carbon fiber bundle with a length of 1.5 mm was calcined at a temperature of 450 ° C for 1 h in a tube furnace, and the surface colloid was removed to make a single carbon fiber;

[0063] (3) In the flocking chamber, place the carbon fiber in the single state prepared in step (2) on the lower electrode plate that is connected to static electricity; fix the viscose fiber fabric coated with acrylate adhesive obtained in step (1) On the upper plate, the ground wire of the upper plate, under the working state, the carbon fiber on the lower plate is neatly implanted on the surface of the viscose fiber fabric coated with acrylic adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com