System and method for removing pollutants in coal-fired flue gas

A coal-fired flue gas and pollutant technology, applied in the field of flue gas purification, can solve the problems of low pollutant removal efficiency and affecting the removal efficiency of adsorbents, and achieve the effect of improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

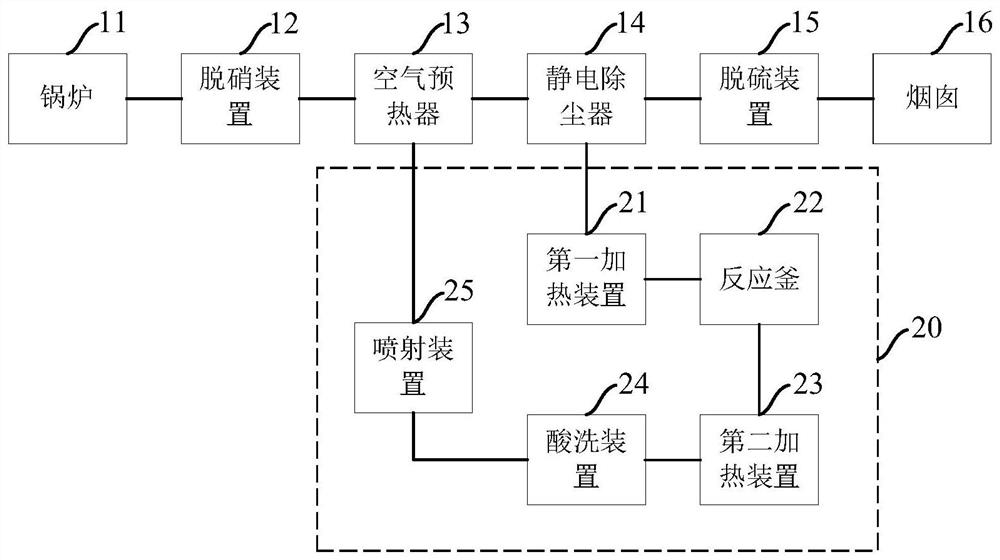

[0061] Such as figure 1 As shown, an embodiment of the present application provides a system for removing pollutants in coal-fired flue gas. The system includes a boiler 11, a denitrification device 12, an air preheater 13, an electrostatic Dust collector 14, desulfurization device 15 and chimney 16;

[0062] The system also includes a bypass system 20, and the bypass system 20 includes: a first heating device 21, a reaction kettle 22, a second heating device 23, a pickling device 24 and a spraying device 25;

[0063] The first end of the first heating device 21 is connected to the electrostatic precipitator, and the first heating device 21 is used to receive and heat the mixture of sodium hydroxide and fly ash produced by the electrostatic precipitator to obtain aluminosilicate;

[0064] The first end of the reactor 22 is connected to the second end of the first heating device 21, and the reactor 22 is used for static aging, crystallization and drying of the solution contain...

Embodiment 2

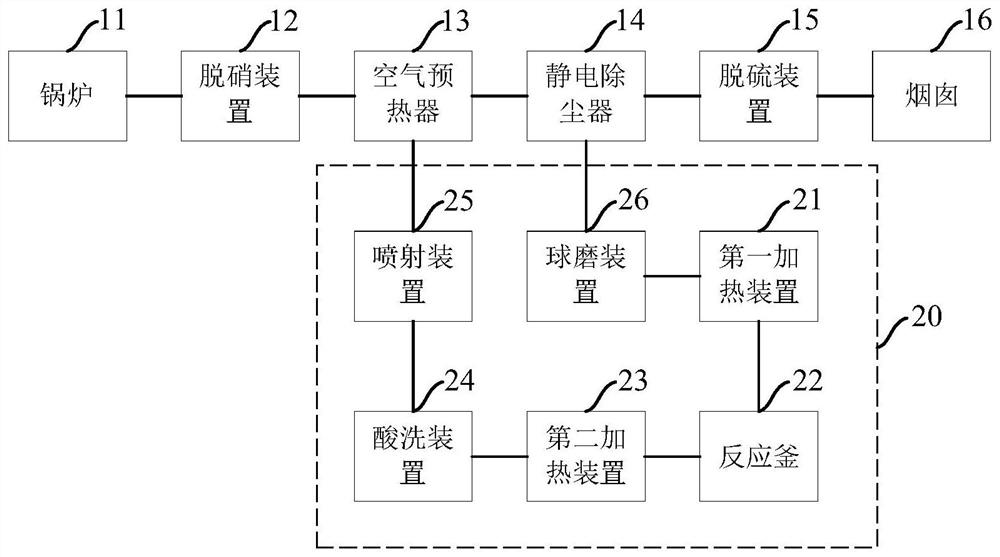

[0075] Different from the first embodiment, on the basis of the first embodiment, the system provided by the second embodiment further includes a grinding device. Such as figure 2 As shown, the bypass system 20 also includes a grinding device 26;

[0076] The first end of the grinding device 26 is connected to the electrostatic precipitator, and the second end of the grinding device 26 is connected to the first end of the first heating device 21. The grinding device 26 is used to receive and grind sodium hydroxide and the fly ash produced by the electrostatic precipitator the mixed mixture;

[0077] The first heating device 21 is used to receive and heat the mixture obtained from the grinding device 26 .

[0078] In this embodiment, setting the grinding device can help increase the specific surface area of the fly ash, so that the contact area and probability of the sodium hydroxide on the surface of the fly ash and the silicon-aluminum element are larger, thereby produci...

Embodiment 3

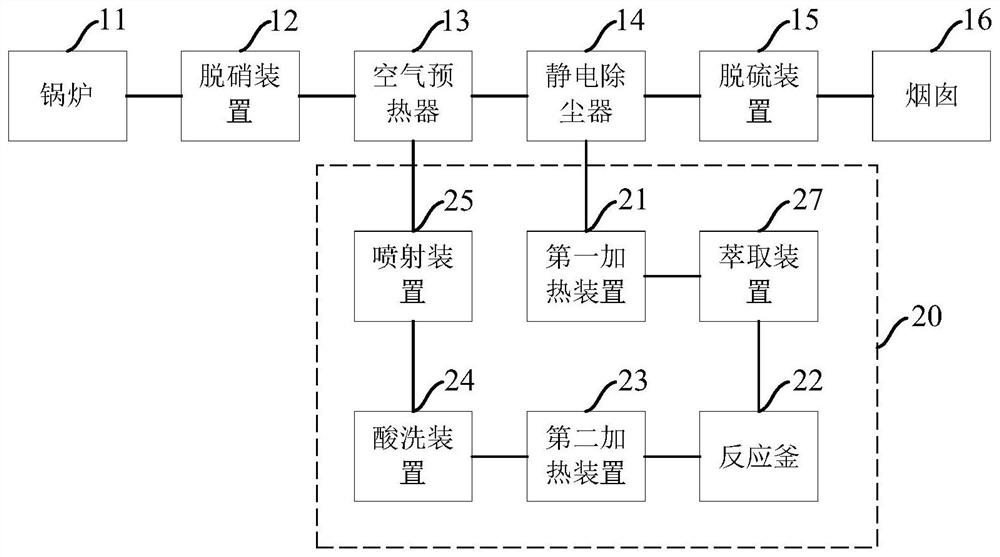

[0080] Different from the first embodiment, on the basis of the first embodiment, the system provided by the third embodiment further includes an extraction device. Such as image 3 As shown, the bypass system 20 also includes an extraction device 27;

[0081] The first end of the extraction device 27 is connected to the second end of the first heating device 21, and the second end of the extraction device 27 is connected to the first end of the reaction kettle 22. The extraction device 27 is used to contain the silicon aluminum obtained by the first heating device 21. The acid salt solution is extracted to obtain rare earth ions;

[0082] The reaction kettle 22 is used for static aging, crystallization and drying of the solution extracted by the extraction device 27 .

[0083] In this embodiment, since the fly ash contains more rare earth elements, the rare earth elements in the fly ash can be extracted by setting an extraction device for recycling.

[0084] Further, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com