Heterojunction photovoltaic cell of grid line electrode without silver paste

A photovoltaic cell and silver paste-free technology, which is applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of high silver content, high purchase cost and high production process requirements of low-temperature silver paste, so as to save light-receiving area, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

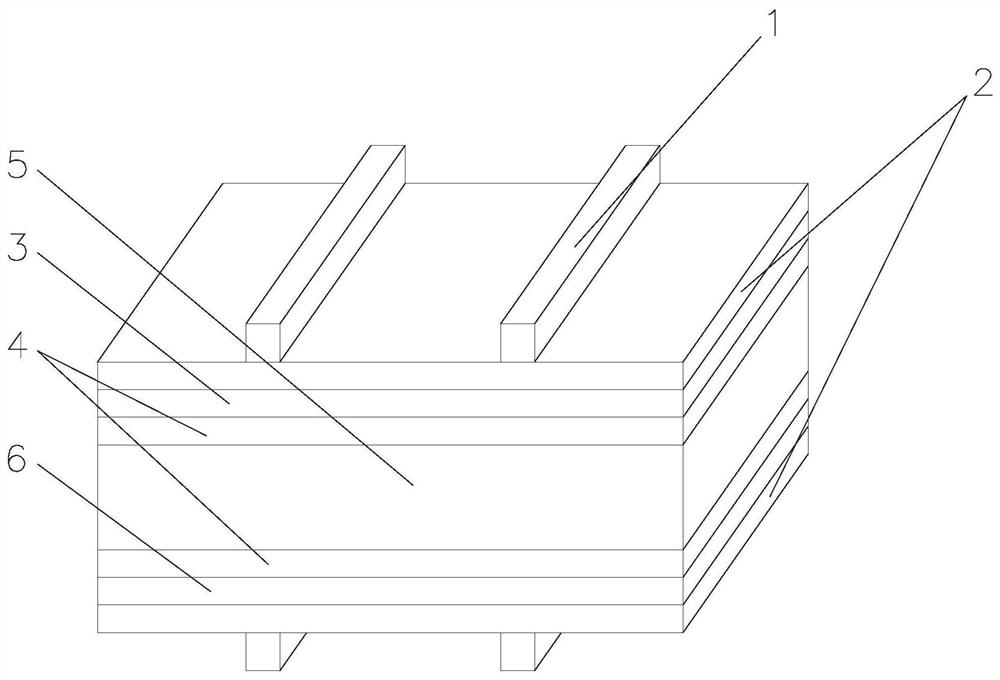

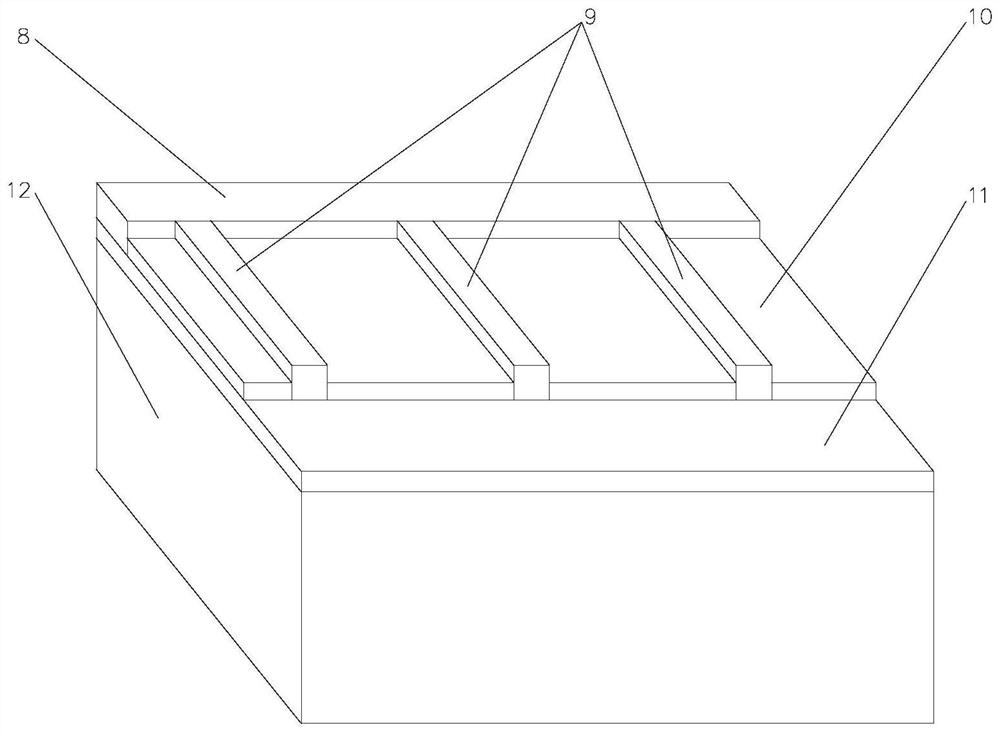

[0049] As shown in the figure, in one embodiment, the implementation of this case uses a 158*158N type single crystal heterojunction non-low temperature silver paste busbar electrode battery. Since there are no fine grid electrodes on both sides of the heterojunction cell, the amount of fine grid silver paste is zero.

[0050] (1) The amount of silver paste used on the grid line electrode of the battery is reduced, which greatly reduces the manufacturing cost of the heterojunction battery,

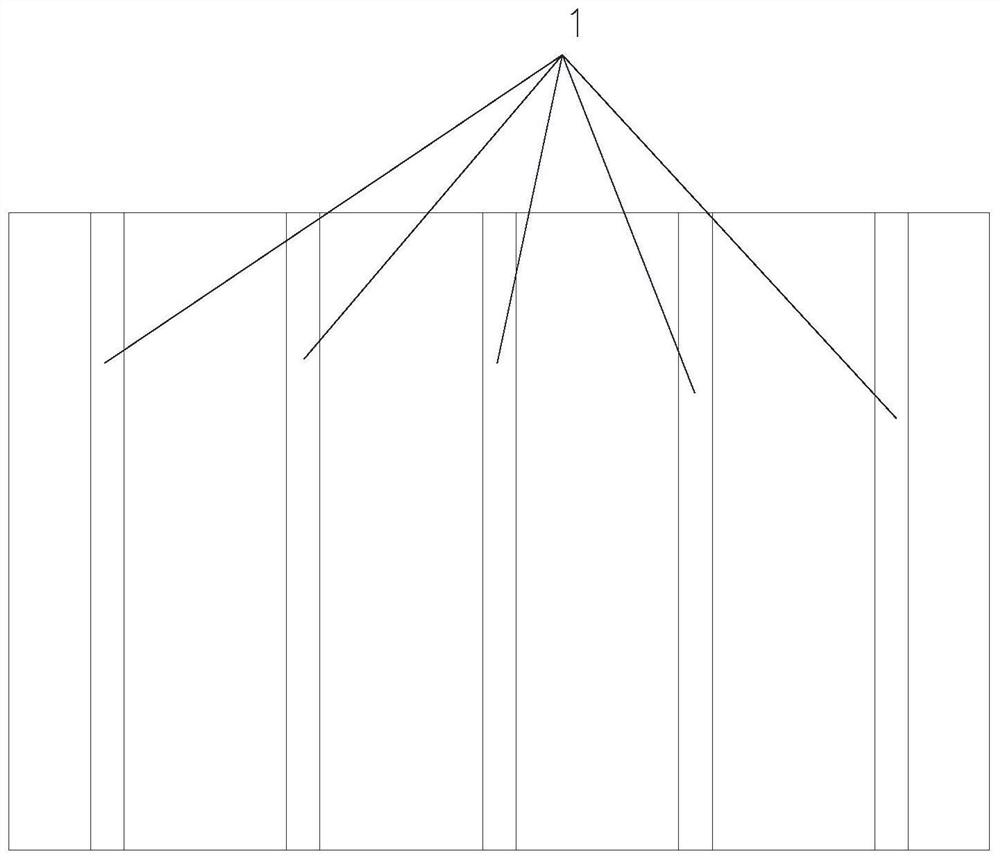

[0051] As for the number of busbars on the cell, the current trend is to adopt a multi-gate electrode structure of 7 to 9 as much as possible, which can reduce the width of the grid lines, thereby reducing the amount of silver paste used to manufacture the grid line electrodes, and reducing the cost of the grid line electrodes. At present, the amount of high-temperature silver paste for PERC crystalline silicon multi-gate electrode cells is reduced to 74mg, which is 40mg less than that of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com