Method for preparing block copolymer hollow fiber membrane by combining selective swelling and melt spinning stretching processes

A technology of melt-spinning stretching and copolymer, which is applied in the field of block copolymer hollow fiber membrane preparation based on selective swelling method, can solve the problems such as the decline of interception performance, the decline of interception performance of hollow fiber membrane, and the impact on the application of hollow fiber membrane. Achieve the effect of improving performance and avoiding the appearance of dense layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 20g PSF 75 -PEG 20 The block copolymer is added into a twin-screw extruder, melted under the condition of nitrogen protection at 200 / 210°C, and then extruded through a spinneret at 200°C, and the stretching rate is adjusted to 260mm / min under water cooling to obtain a drawn Hollow fiber with a stretch ratio of 247%. The obtained hollow fiber was immersed in a mixed solvent of n-propanol and acetone containing 20wt% acetone, treated in a water bath at 65° C. for 1 h, and then transferred to n-octane for 12 h. Immediately after the treatment, the hollow fiber was taken out and dried at 40° C. to obtain a hollow fiber membrane.

[0037] The pure water flux of the polysulfone / polyethylene glycol hollow fiber membrane prepared in this example is 84L m -2 h -1 · bar -1 About 60% of bovine serum albumin with a diameter of about 6nm is rejected.

Embodiment 2

[0039] 20g PSF 75 -PEG 20 The block copolymer was added into a twin-screw extruder, melted under nitrogen protection conditions at 200 / 210°C, and then extruded through a spinneret at 200°C, and the stretching rate was adjusted to 360mm / min under natural cooling to obtain Hollow fiber with a draw ratio of 380%. The obtained hollow fiber was immersed in a mixed solvent of n-propanol and acetone containing 20wt% acetone, treated in a water bath at 65° C. for 1 h, and then transferred to n-heptane for 6 h. Immediately after the treatment, the hollow fiber was taken out and dried at 40° C. to obtain a hollow fiber membrane.

[0040] The pure water flux of the polysulfone / polyethylene glycol hollow fiber membrane prepared in this example is 89L m -2h -1 · bar -1 About 68% of bovine serum albumin with a diameter of about 6nm is rejected.

Embodiment 3

[0042] 20g PSF 75 -PEG 20 The block copolymer was added into a twin-screw extruder, melted under nitrogen protection at 200 / 210°C, and then extruded through a spinneret at 200°C, and the stretching rate was adjusted to 470mm / min under natural cooling to obtain A hollow fiber with a draw ratio of 527%. The obtained hollow fiber was immersed in a mixed solvent of n-propanol and acetone containing 20 wt% acetone, treated in a water bath at 65° C. for 1 h, and then transferred to n-heptane for 1 h. Immediately after the treatment, the hollow fiber was taken out and dried at 40° C. to obtain a hollow fiber membrane.

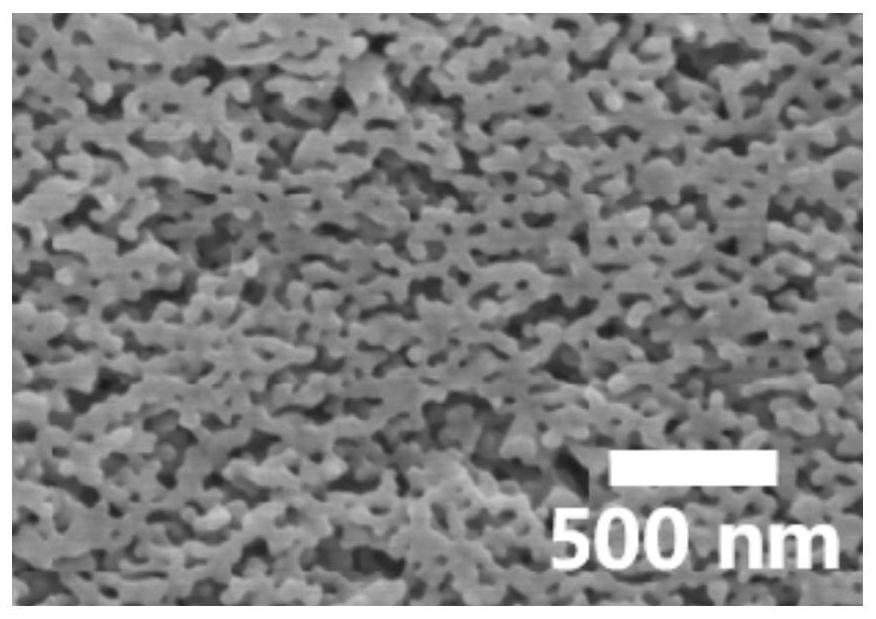

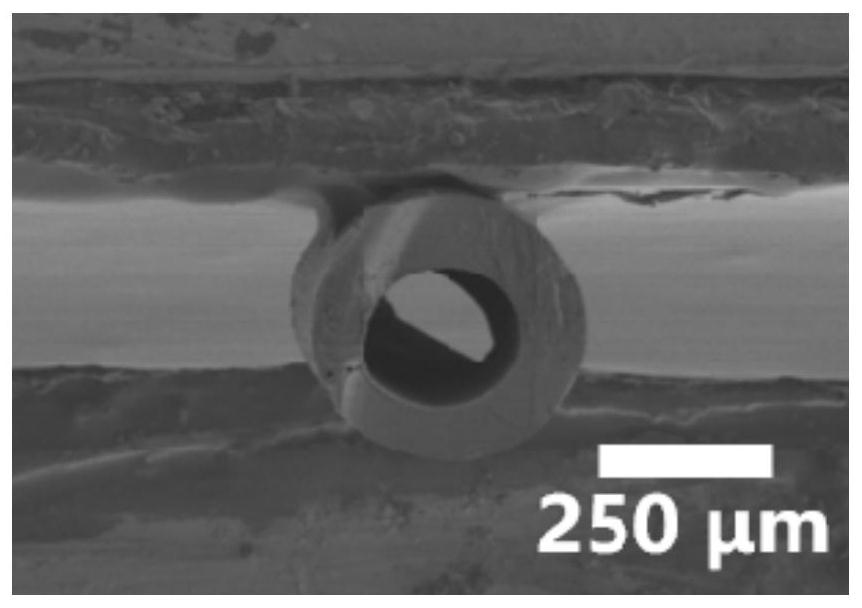

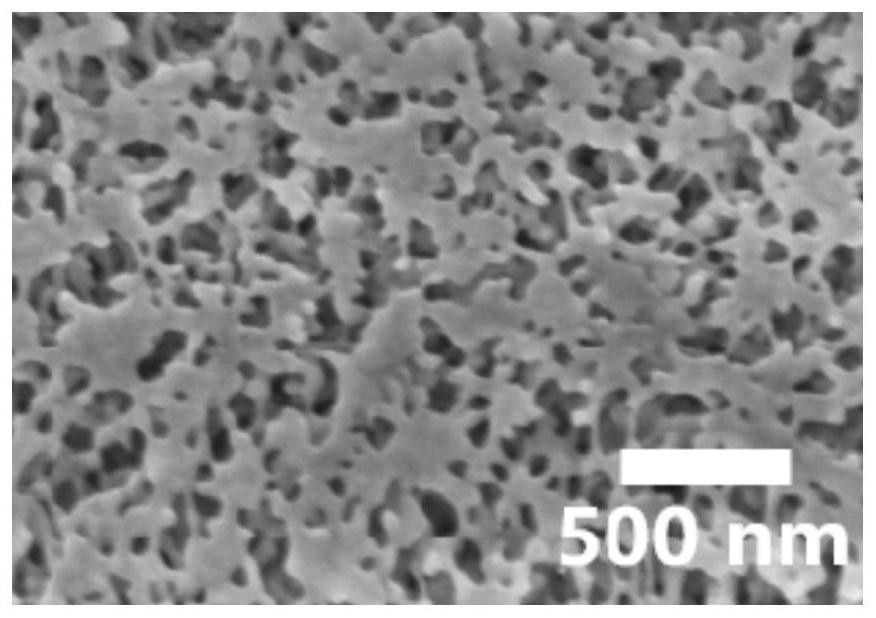

[0043] figure 1 , figure 2 The SEM images of the outer surface and section of the polysulfone / polyethylene glycol hollow fiber membrane prepared in this example are respectively. It can be seen from the figure that the polysulfone / polyethylene glycol hollow fiber membrane after high-speed stretching has a good open-pore structure, and the channels have obvious t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com