CuO composite photocatalytic nanomaterial and efficient preparation method thereof

A composite photocatalysis and nanomaterial technology, applied in the field of CuO composite photocatalytic nanomaterials and their efficient preparation, can solve the problems of uneven distribution of CuO particles, long preparation period, large energy consumption, etc., and achieves increased photothermal response rate, The effect of low cost and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

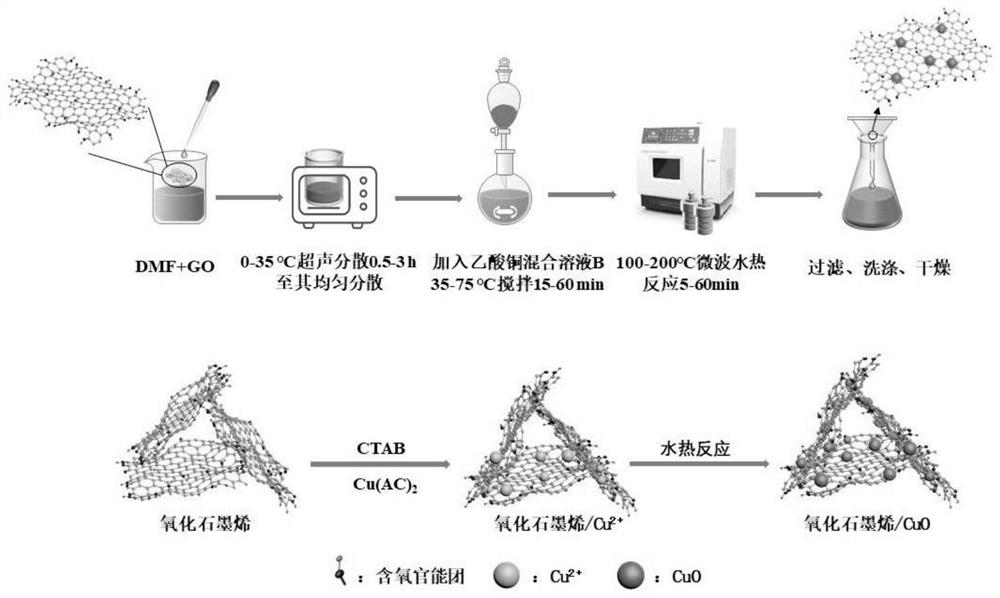

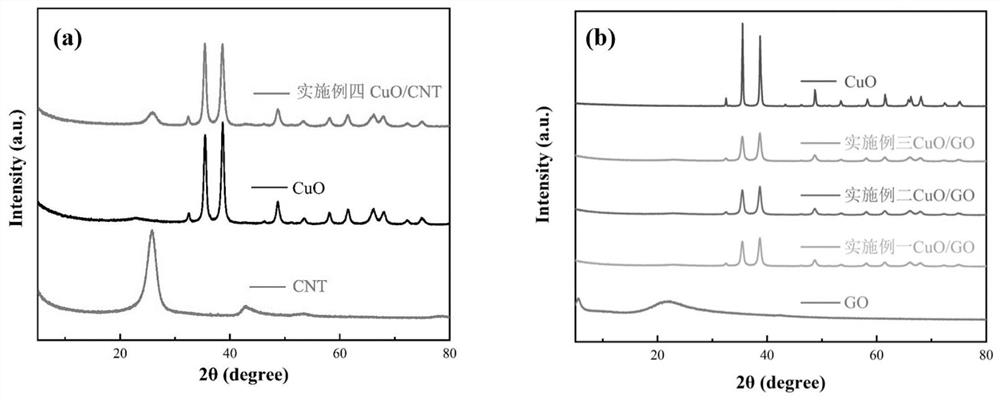

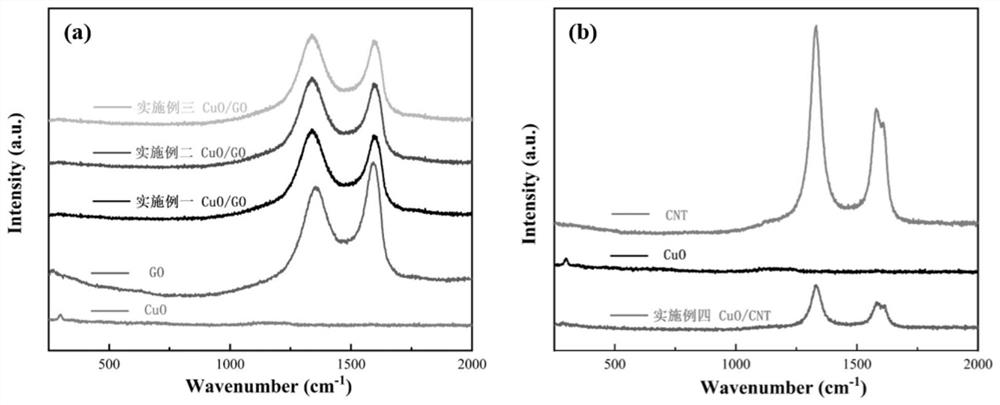

[0035] A CuO composite photocatalytic nanomaterial, with graphene oxide (GO) as the carrier and CuO as the loading material, is prepared by a step-by-step microwave hydrothermal method. The specific preparation method includes the following steps:

[0036] (1) Pretreatment: Disperse 80mg of GO in 60ml of deionized water according to the weight and place it in an ultrasonic disperser at 30°C for 2 hours to obtain a GO dispersion;

[0037] 400mg Cu(AC) 2 , 12mg NaOH and 40mg CTAB were added to 10ml deionized water and stirred evenly for later use to obtain a mixed solution;

[0038] Add the mixed liquid dropwise to the GO dispersion liquid and heat it in a mixed water bath at 45°C for 40 minutes, with a stirring speed of 600-800rmp to prepare a precursor solution;

[0039] (2) Microwave hydrothermal method: Add the prepared precursor solution into a polychlorotetrafluoroethylene reactor, place the reactor in a microwave hydrothermal synthesizer, heat it to 160°C for 30 minutes...

Embodiment 2

[0044] A CuO composite photocatalytic nanomaterial, with graphene oxide (GO) as the carrier and CuO as the loading material, is prepared by a step-by-step microwave hydrothermal method. The specific preparation method includes the following steps:

[0045] (1) Pretreatment: Disperse 80mg of GO in 60ml of deionized water according to the weight and place it in an ultrasonic disperser at 30°C for 2 hours to obtain a GO dispersion;

[0046] 200mg Cu(AC) 2 , 8mg NaOH and 20mg CTAB were added to 5ml deionized water and stirred evenly for later use to obtain a mixed solution;

[0047] The mixed liquid was added dropwise to the GO dispersion liquid and heated in a mixed water bath at 45° C. for 40 min at a stirring speed of 600-800 rpm to obtain a precursor solution.

[0048] (2) Microwave hydrothermal method: Add the prepared precursor solution into a polychlorotetrafluoroethylene reaction kettle, place the reaction kettle in a microwave hydrothermal synthesizer with a microwave f...

Embodiment 3

[0052] A CuO composite photocatalytic nanomaterial, with graphene oxide (GO) as the carrier and CuO as the loading material, is prepared by a step-by-step microwave hydrothermal method. The specific preparation method includes the following steps:

[0053] (1) Pretreatment: Disperse 80mg of GO in 60ml of deionized water according to the weight and place it in an ultrasonic disperser at 30°C for 2 hours to obtain a GO dispersion;

[0054] 400mg Cu(AC) 2 , 15mg NaOH and 40mg CTAB were added to 10ml deionized water and stirred evenly for later use to obtain a mixed solution;

[0055] The mixed liquid was added dropwise to the GO dispersion liquid and heated in a mixed water bath at 40° C. for 30 min with a stirring speed of 600-800 rpm to obtain a precursor solution.

[0056] (2) Microwave hydrothermal method: Add the prepared precursor solution into a polychlorotetrafluoroethylene reaction kettle, place the reaction kettle in a microwave hydrothermal synthesizer with a microwa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com