High-heat-dissipation metal substrate for LED and preparation method thereof

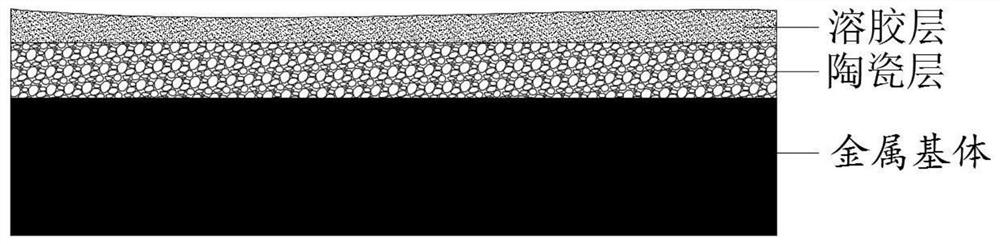

A metal substrate and function technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of high cost, complicated process, and reduced thermal conductivity, so as to improve insulation performance, strong adhesion, and improve thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Example 1: A high heat dissipation metal substrate for LEDs:

[0086] This embodiment provides a high heat dissipation metal substrate for LEDs, the preparation method of which includes:

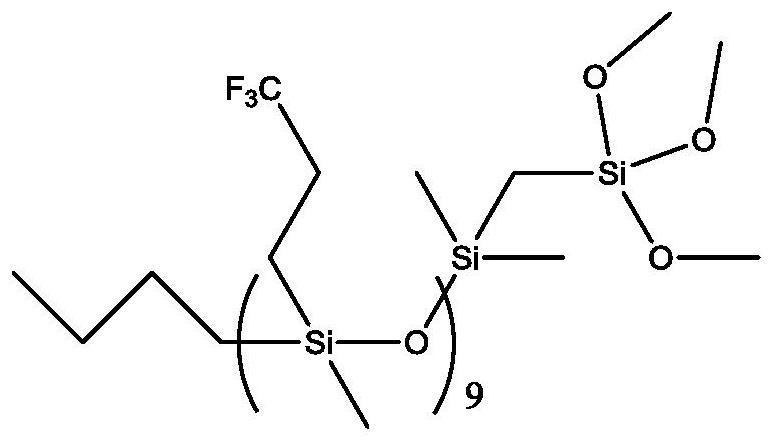

[0087] S1: Preparation of fluorine-containing silane coupling agent modified graphene oxide: prepare an absolute ethanol solution of fluorine-containing silane coupling agent shown in formula (1) with a mass fraction of 2%, according to the weight ratio of coupling agent to graphene oxide It is 2:1, slowly added to 4mg / mL graphene oxide aqueous solution within 2h, at ultrasonic frequency 35KHz, ultrasonic intensity 0.5W / cm 2 1. Disperse at a stirring rate of 150r / min for 1.5h until the system is uniform, then adjust the pH of the solution to 3.0 with 2mol / L hydrochloric acid, raise the temperature to 50°C at 5°C / min for 8h, then raise the temperature to 70°C for 2h, filter with Wash with pure water, dry at 50°C for 45 minutes, and grind until the particle size is not greater than 100...

Embodiment 2

[0106] Example 2: A metal substrate with high heat dissipation for LEDs:

[0107] This embodiment provides a high heat dissipation metal substrate for LEDs, the preparation method of which includes:

[0108] S1: Preparation of fluorine-containing silane coupling agent modified graphene oxide: prepare an absolute ethanol solution of fluorine-containing silane coupling agent shown in formula (1) with a mass fraction of 2.5%, according to the weight ratio of coupling agent to graphene oxide It is 2.5:1, slowly added to the graphene oxide aqueous solution with a concentration of 3.5mg / mL within 1.5 minutes, at an ultrasonic frequency of 50KHz and an ultrasonic intensity of 0.6W / cm 2 , Disperse at 180r / min for 1h until the system is uniform, then adjust the pH of the solution to 3.2 with 2mol / L hydrochloric acid, raise the temperature to 55°C at 4°C / min for 6h, then raise the temperature to 70°C for 3h, filter and wash with pure water , dried at 55°C for 30 minutes, and ground to ...

Embodiment 3

[0127] Embodiment 3: A metal substrate with high heat dissipation for LEDs:

[0128] This embodiment provides a high heat dissipation metal substrate for LEDs, the preparation method of which includes:

[0129] S1: Preparation of modified graphene oxide: prepare an absolute ethanol solution of (3,3,3-trifluoropropyl)trimethoxysilane with a mass fraction of 2.5%, according to the weight ratio of coupling agent to graphene oxide is 2.5 : 1, slowly added to the graphene oxide aqueous solution with a concentration of 3.5mg / mL within 1.5 hours, at an ultrasonic frequency of 50KHz and an ultrasonic intensity of 0.6W / cm 2 , Disperse at 180r / min for 1h until the system is uniform, then adjust the pH of the solution to 3.2 with 2mol / L hydrochloric acid, raise the temperature to 55°C at 4°C / min for 6h, then raise the temperature to 70°C for 3h, filter and wash with pure water , dried at 55°C for 30 minutes, and ground to a particle size not greater than 100 μm;

[0130] S2: preparing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com