Emulsion paint for external wall and preparation method of emulsion paint

A latex paint and pre-emulsion technology, applied in the field of latex paint for exterior walls and its preparation, can solve the problems of poor water permeability, anti-salt and alkali resistance, poor film-forming performance, and alkaline bleed, etc., and achieve easy operation , improve the quality, the effect of high cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

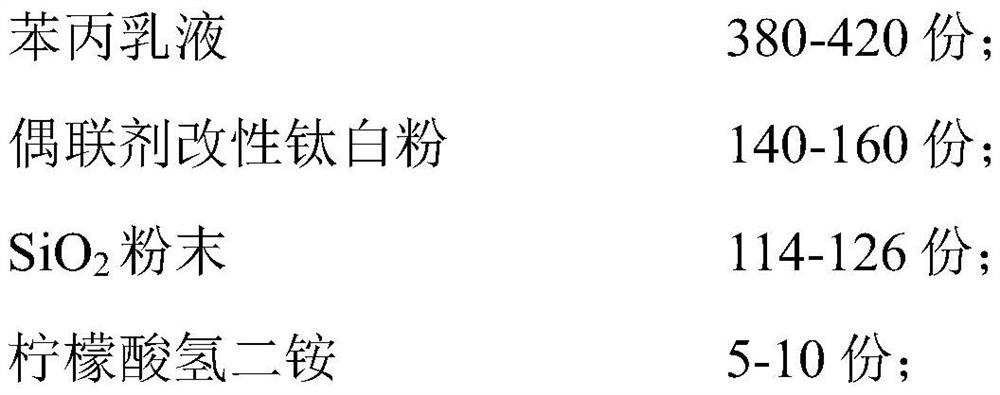

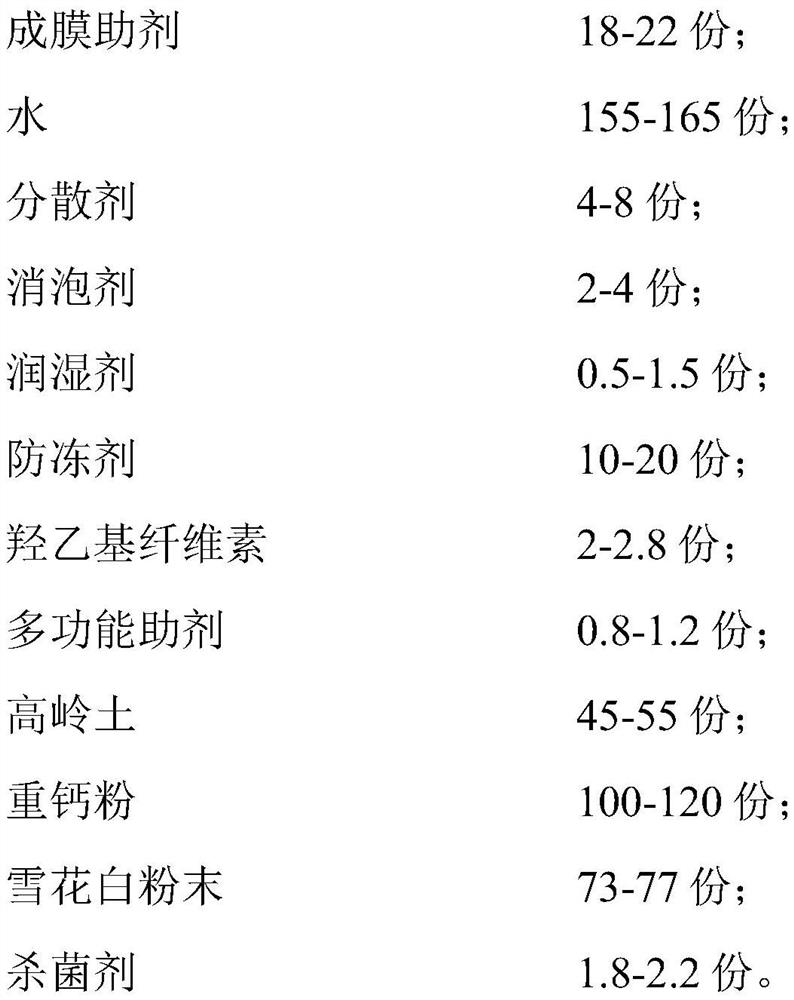

Method used

Image

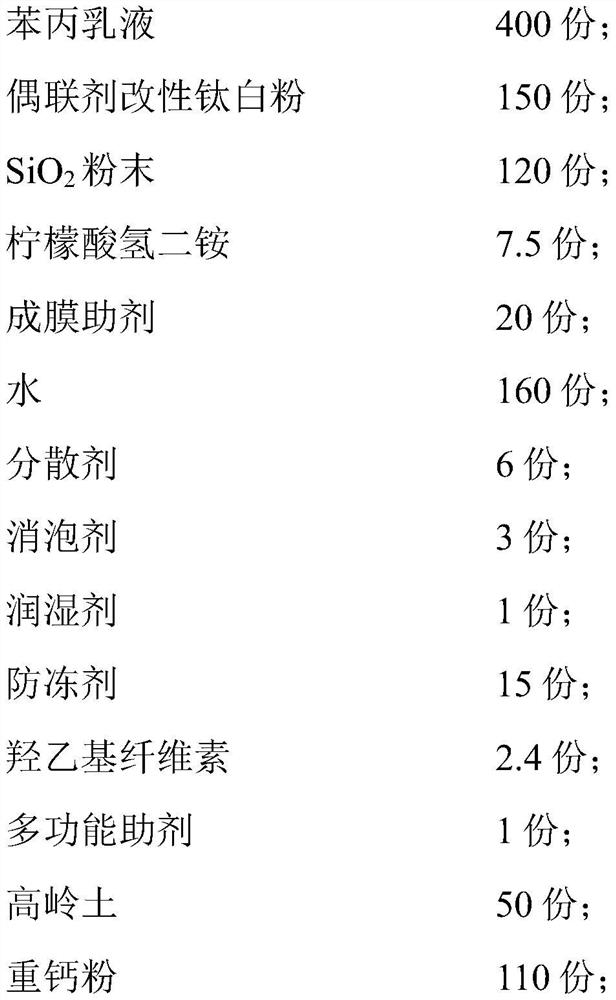

Examples

preparation example 1

[0064] Coupling agent modified titanium dioxide is prepared by the following method:

[0065] At a temperature of 65°C, mix and stir 200kg of titanium dioxide and water for 10 minutes to obtain a titanium dioxide slurry with a mass fraction of 40%, then add 300kg of titanate coupling agent and mix evenly, react for 1 hour, filter, and temperature, and dried for 50 minutes to obtain coupling agent-modified titanium dioxide.

preparation example 2

[0067] Coupling agent modified titanium dioxide is prepared by the following method:

[0068] At a temperature of 67.5°C, mix and stir 200kg of titanium dioxide and water for 12.5 minutes to obtain a titanium dioxide slurry with a mass fraction of 42.5%, then add 350kg of silane coupling agent and mix evenly, react for 1.25h, filter, and temperature, and dried for 55 minutes to obtain coupling agent-modified titanium dioxide.

preparation example 3

[0070] Coupling agent modified titanium dioxide is prepared by the following method:

[0071] At a temperature of 70°C, mix and stir 200kg of titanium dioxide and water for 15 minutes to obtain a titanium dioxide slurry with a mass fraction of 45%, then add 400kg of silane coupling agent and mix evenly, react for 1.5h, filter, and filter at a temperature of 90°C , dried for 60 minutes to obtain coupling agent modified titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com