Quick-dry high-strength peelable film for radioactive surface decontamination and preparation method thereof

A radioactive and peeling film technology, used in coatings, conjugated diene coatings, polyether coatings, etc., can solve the problems of large environmental humidity, inability to dry quickly, poor film-forming effect, etc., to improve the peeling effect. , The effect of fast drying and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

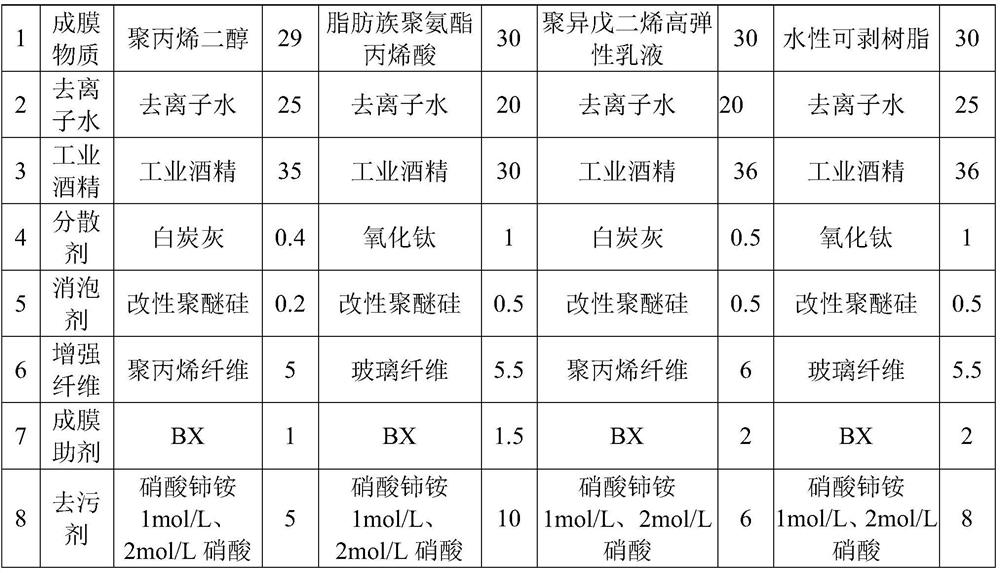

Embodiment 1

[0045] Take nitric acid and ammonium cerium nitrate with a volume ratio of 1:1 in a beaker in turn, stir for 15 minutes to obtain a detergent; take another beaker, and add deionized water and industrial alcohol to it in turn, stir for 5 minutes, and then add Stir polypropylene glycol, modified polyether silicon, and white carbon for 1 hour to obtain a film-forming agent; add detergent and polypropylene fiber to the film-forming agent in sequence, and stir for 20 minutes to obtain a quick-drying high-strength Peelable film.

Embodiment 2

[0047] Aliphatic urethane acrylic acid is used as the film-forming material, nano-titanium oxide powder is used as the dispersant, glass fiber is used as the reinforcing fiber, other compositions are the same as in Example 1, and the preparation process is the same as in Example 1.

Embodiment 3

[0049] Polyisoprene high elastic emulsion is used as the film-forming substance, white carbon ash is used as the dispersant, polypropylene fiber is used as the reinforcing fiber, other compositions are consistent with Example 1, and the preparation process is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com