Preparation method and application of microcapsule burst bead

A technology of microcapsules and explosive beads, applied in the field of daily chemical products, can solve the problems of poor biodegradability of microcapsules, such as precipitation and stratification, and achieve good biocompatibility and biodegradability, long shelf life and adjustable taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] (1) Preparation of slow-release flavor popping beads matrix: take chitosan and dissolve it in 1% acetic acid solution, so that the concentration of chitosan is 0.1g / L, add lavender essence and Tween-80 to the chitosan solution , stir evenly to form an O / W emulsion, then dropwise add 0.5g / L sodium tripolyphosphate solution, stir and cross-link to obtain microcapsules; add xanthan gum to obtain a pop-bead matrix.

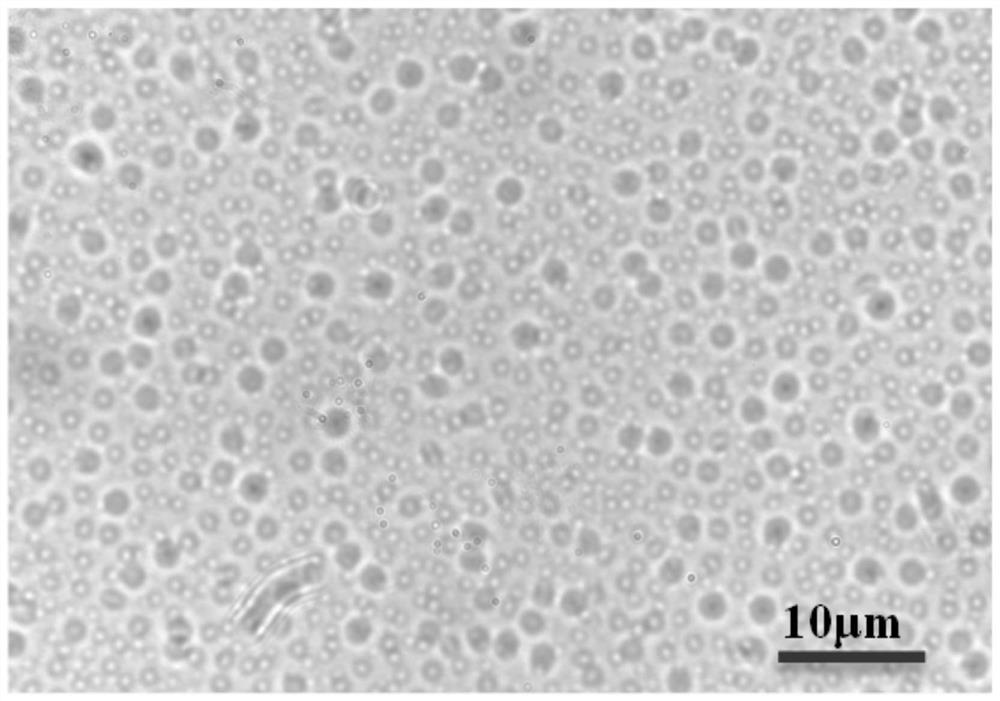

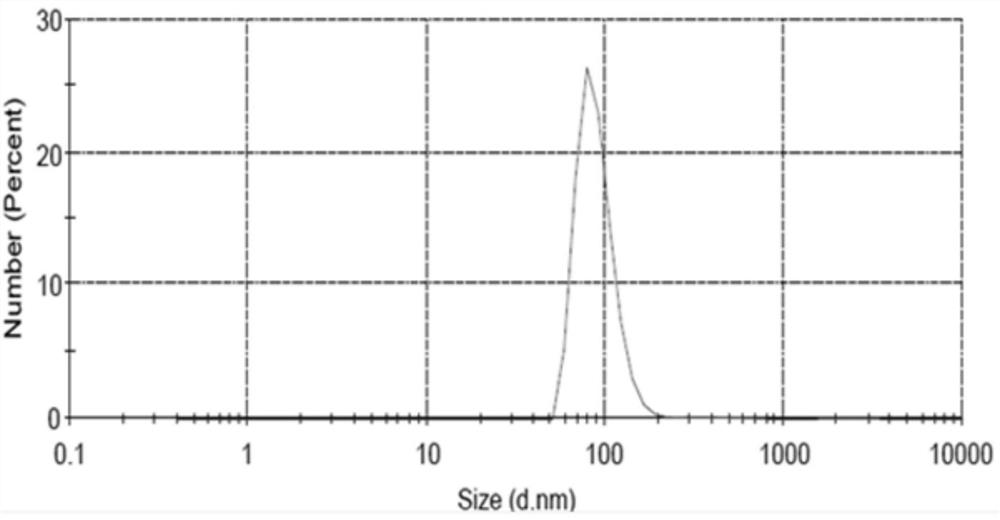

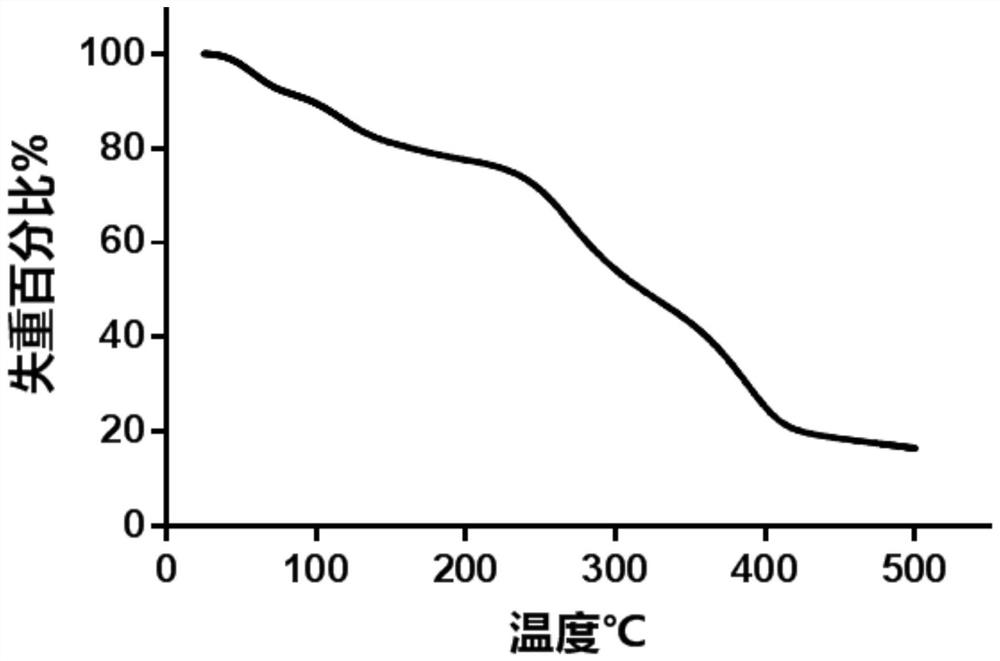

[0086] (2) Popping bead forming: mix the popping bead matrix with an equal volume of 2% calcium chloride solution, stir evenly and drop into 0.2% sodium alginate solution to obtain the product. Electron micrograph, particle size and thermogravimetric analysis of the prepared microcapsule quick-fried beads are as follows: figure 1 , figure 2 , image 3 shown.

Embodiment 2

[0088] (1) Preparation of slow-release flavor popping beads matrix: take chitosan and dissolve it in 0.5% acetic acid solution, so that the concentration of chitosan is 1g / L, add rose essence and lecithin in chitosan solution, stir Uniformly form an O / W emulsion, then add 0.5g / L sodium tripolyphosphate solution drop by drop, stir and cross-link to obtain the popping pearl matrix; add xanthan gum to obtain the popping pearl matrix.

[0089] (2) Bead forming: Stir the bead base and 10% calcium carbonate solution of equal volume and drop them evenly into 0.2% sodium alginate and 10% modified gelatin solution containing photoinitiator to obtain the product.

Embodiment 3

[0091] (1) Preparation of slow-release flavor popping beads matrix: take chitosan and dissolve it in 1% acetic acid solution, so that the concentration of chitosan is 3g / L, add sweet orange essence and Tween-80 to the chitosan solution , stir evenly to form an O / W emulsion, then add 1g / L sodium sulfate solution drop by drop, stir and cross-link to obtain the popping pearl matrix; add xanthan gum to obtain the popping pearl matrix.

[0092] (2) Popping bead forming: stir the popping bead base and 50% calcium chloride solution of equal volume and drop them evenly into 0.2% gelatin solution to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com