Method for metallizing and electroplating only hole wall

A hole metallization and metallization technology is applied in the field of circuit board manufacturing technology to achieve the effects of simple hole metallization, good effect and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] This embodiment takes a double-sided printed circuit board as an example, and the specific processing steps are as follows:

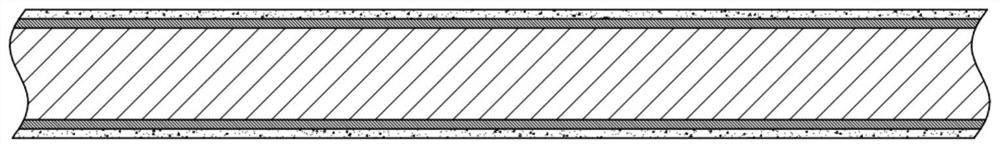

[0087] (1) Deposit parylene on the entire double-sided printed circuit board to form a masking layer 1, such as figure 1 as shown,

[0088] Specifically, the parylene coating produced by Xiayu Nanotechnology was deposited on the surface of the double-sided circuit board by vacuum vapor deposition, and the thickness of the coating was about 3um.

[0089] The prior art generally uses photo-induced dry film as an anti-plating mask. The photo-induced dry film has a three-layer structure. The photosensitive adhesive coating is between the carrier film and the protective film and is composed of adhesive and photopolymerizable monomer. It is complicated, and it needs to go through the process of photo-drawing, filming, exposure, and development; moreover, it is expensive, the strength is not high, and the thickness is relatively large, generally above...

Embodiment 2

[0119] This embodiment takes a 4-layer printed circuit board as an example, and the specific processing steps are as follows:

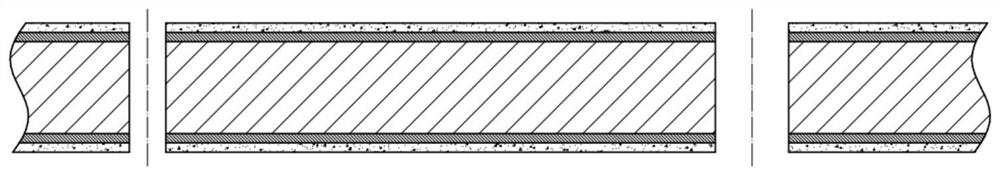

[0120] (1) On the 4-layer circuit board that has completed the inner layer circuit and laminated, double-sided heat-pressed composite RPP film, such as Figure 7 shown.

[0121] Specifically, heat-press composite RPP film, the thickness of the film is about 10um, and the bonding parameters are: pressure 15kg / cm 2 , temperature 100°C, speed 0.1m / min.

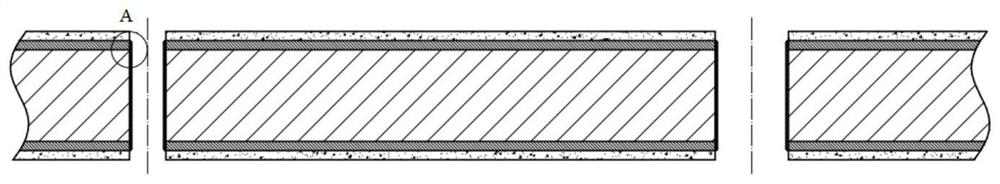

[0122] (2) After direct laser drilling or mechanical drilling, the laser is used to remove the slag on the hole wall, such as Figure 8 shown.

[0123] Specifically, in this embodiment, the hole is mechanically drilled first, and then the hole is expanded by a femtosecond laser beam, so as to finally meet the aperture requirement. The mechanical drilling uses the DCT-DM350 equipment produced by Dezhong Technology Co., Ltd. to drill holes according to the design requirements. Import the designed data...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com